Understanding Mixer Settlers: From Lab to Industrial Scale

The Fundamentals of Mixer Settler Technology

Mixer settlers are essential equipment in various industries, including chemical processing, hydrometallurgy, and pharmaceutical manufacturing. These versatile devices combine mixing and settling stages to facilitate liquid-liquid extraction processes. The mixer section promotes intimate contact between two immiscible liquids, allowing for efficient mass transfer of desired components. Subsequently, the settler section enables the separation of the mixed phases through gravity settling.

Key Components and Working Principles

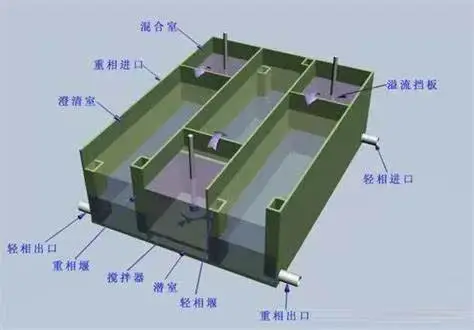

Both laboratory mixer settler, laboratory and industrial mixer settlers share common components, including mixing chambers, impellers, and settling zones. The mixing chamber is where the aqueous and organic phases are brought into contact, creating a dispersion. Impellers generate the necessary turbulence for thorough mixing. In the settling zone, the dispersed phases separate based on density differences, allowing for the collection of purified products.

Scaling Up: From Bench to Production

The transition from laboratory to industrial scale mixer settlers involves significant considerations. While the basic principles remain the same, factors such as flow rates, residence times, and interfacial areas must be carefully scaled up. Industrial mixer settlers often incorporate additional features like automated controls, continuous operation capabilities, and enhanced safety measures to meet the demands of large-scale production environments.

Laboratory Mixer Settlers: Precision and Flexibility in Research

Advantages of Laboratory-Scale Units

Laboratory mixer settlers offer numerous benefits for research and development applications. These compact units provide excellent control over experimental parameters, allowing scientists to fine-tune extraction conditions with precision. The smaller scale enables rapid testing of various process conditions, facilitating the optimization of separation efficiency and selectivity. Additionally, laboratory mixer settlers typically require minimal sample volumes, making them ideal for working with expensive or limited reagents.

Applications in Process Development

In the realm of process development, laboratory mixer settlers play a crucial role. They serve as valuable tools for screening different solvent systems, investigating extraction kinetics, and evaluating the effects of pH, temperature, and other variables on separation performance. Researchers can use these units to generate essential data for process modeling and scale-up studies, laying the groundwork for successful industrial implementation.

Customization and Modularity

One of the key advantages of laboratory mixer settlers is their adaptability. Many models offer modular designs, allowing researchers to configure multiple stages in series or parallel arrangements. This flexibility enables the simulation of complex multistage extraction processes on a small scale. Furthermore, laboratory units often feature interchangeable components, such as different impeller designs or settling chamber geometries, facilitating the exploration of various process configurations.

Industrial Mixer Settlers: Robust Performance for Large-Scale Production

Capacity and Throughput Considerations

Industrial mixer settlers are engineered to handle substantial volumetric flow rates and achieve high throughput in continuous operations. These large-scale units are designed with increased mixing and settling volumes, allowing for efficient processing of industrial-scale batches. The enhanced capacity of industrial mixer settlers makes them suitable for applications in mineral processing, petrochemical refining, and bulk chemical production, where handling large quantities of material is essential.

Advanced Features for Process Optimization

To meet the demands of industrial-scale operations, mixer settlers at this level incorporate advanced features for process optimization. Automated control systems enable precise regulation of mixing speeds, phase ratios, and residence times. Many industrial units are equipped with inline monitoring capabilities, allowing for real-time adjustments to maintain optimal performance. Additionally, robust construction materials and designs ensure durability and reliability in challenging industrial environments.

Integration with Broader Production Systems

Industrial mixer settlers are often integrated into comprehensive production systems, forming part of larger extraction trains or hydrometallurgical circuits. These units can be seamlessly connected with other process equipment such as pumps, heat exchangers, and filtration systems. The ability to integrate mixer settlers into automated production lines enhances overall process efficiency and enables the implementation of sophisticated control strategies for maximizing yield and product quality.

Conclusion

Choosing between laboratory and industrial mixer settlers depends on your specific needs and operational context. Laboratory units excel in research, process development, and small-scale applications, offering precision and flexibility. Industrial mixer settlers are the go-to choice for large-scale production, providing robust performance and high throughput. By carefully evaluating your requirements, including scale, application complexity, and future scalability, you can select the most appropriate mixer settler technology to optimize your extraction processes and achieve your production goals.

Contact Us

For expert guidance on selecting the right mixer settler for your needs, reach out to Cuiyan Technology. Our team of specialists can help you navigate the options and find the perfect solution to enhance your extraction processes. Contact us at wangzhijun@cuiyan-tec.com to explore how our advanced extraction equipment can benefit your operations.