Comparing Metal and Plastic Mixer Settlers: Performance and Durability

Material Properties and Their Impact on Extraction Efficiency

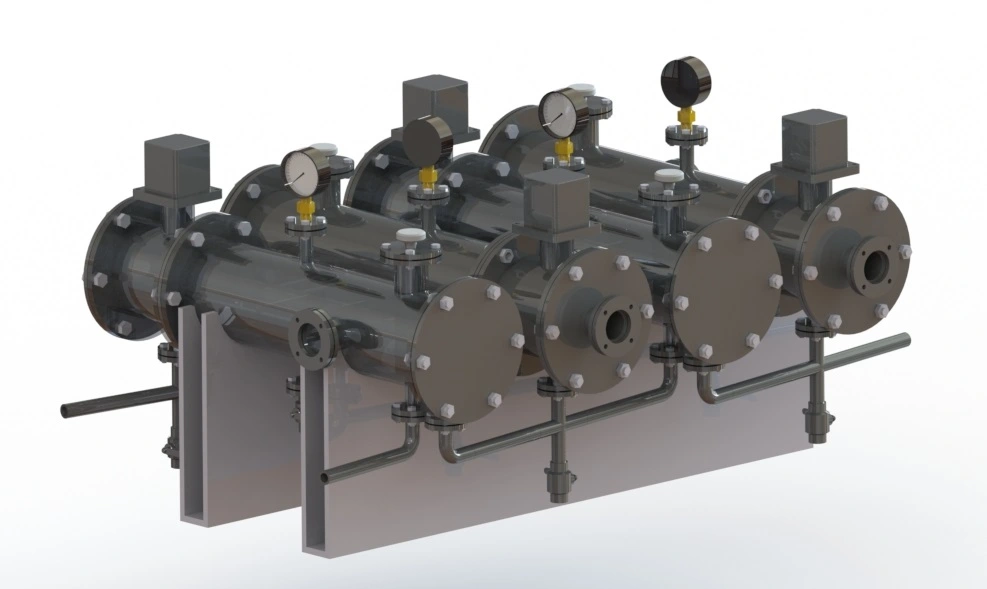

Metal mixer settlers, typically constructed from stainless steel or other corrosion-resistant alloys, offer superior strength and stability. This robustness allows for higher operating pressures and temperatures, making them suitable for demanding extraction processes. The thermal conductivity of metal also promotes efficient heat transfer, which can be advantageous in temperature-sensitive applications. Plastic mixer settlers, often made from materials like polypropylene or PVDF, provide excellent chemical resistance and are lighter in weight. Their non-reactive nature makes them ideal for handling corrosive substances without the risk of contamination. However, plastic settlers may have limitations in terms of operating temperatures and pressure capabilities compared to their metal counterparts.

Longevity and Maintenance Requirements

The durability of metal mixer settlers is a significant advantage, with many units lasting for decades with proper maintenance. Their robust construction makes them resistant to wear and tear, reducing the frequency of repairs and replacements. However, metal settlers may require periodic inspections and treatments to prevent corrosion, especially in harsh chemical environments. Plastic mixer settlers, while generally having a shorter lifespan, offer the benefit of being corrosion-free. This characteristic can translate to lower maintenance costs and reduced downtime for cleaning and repairs. The choice between metal and plastic often depends on the specific chemicals involved in the extraction process and the expected operational lifespan of the equipment.

Adaptability and Customization Options

Metal mixer settlers provide greater flexibility in terms of design modifications and customization. Their structural integrity allows for easier retrofitting and upgrades, which can be beneficial as process requirements evolve over time. Welding and machining techniques can be employed to make alterations or repairs on-site. Plastic mixer settlers, while less adaptable in terms of structural changes, offer advantages in modular design. They can be easily assembled and disassembled, facilitating transportation and installation in confined spaces. The lightweight nature of plastic also allows for more straightforward reconfiguration of extraction setups when needed.

Economic Considerations: Initial Costs vs. Long-term Value

Upfront Investment and Installation Expenses

The initial cost of metal mixer settlers is typically higher due to the materials used and the manufacturing processes involved. Stainless steel and other corrosion-resistant alloys come at a premium, reflecting in the equipment's price. Installation of metal settlers may also require more specialized equipment and skilled labor, potentially increasing upfront expenses. Plastic mixer settlers, conversely, offer a more budget-friendly initial investment. The raw materials and manufacturing processes for plastic components are generally less expensive, resulting in lower purchase prices. Their lightweight nature can also lead to reduced transportation and installation costs, making them an attractive option for projects with tight budgets or in remote locations.

Operational Costs and Energy Efficiency

When evaluating the long-term economic impact, it's crucial to consider operational costs. Metal mixer settlers often demonstrate superior energy efficiency due to their excellent heat transfer properties. This can lead to reduced energy consumption in processes that require temperature control, potentially offsetting the higher initial investment over time. Plastic mixer settlers, while potentially less energy-efficient in heat transfer, may offer advantages in terms of pumping costs due to their lighter weight and smoother internal surfaces. The choice between metal and plastic can significantly impact ongoing operational expenses, making it essential to analyze the specific requirements of your extraction process.

Lifecycle Analysis and Replacement Frequency

A comprehensive cost-effectiveness assessment must include a lifecycle analysis of both metal and plastic mixer settlers. Metal units, with their extended lifespan, may provide better value over the long term despite higher upfront costs. The durability of metal settlers can translate to fewer replacements and reduced downtime for maintenance, contributing to overall cost savings. Plastic mixer settlers, while potentially requiring more frequent replacements, offer the advantage of easier and less expensive replacement processes. The decision between metal and plastic should consider the projected operational life of the extraction facility and the anticipated frequency of equipment upgrades or replacements.

Environmental and Safety Considerations in Mixer Settler Selection

Ecological Impact and Sustainability

The environmental implications of choosing between metal and plastic mixer settlers are becoming increasingly important in today's eco-conscious industrial landscape. Metal settlers, particularly those made from stainless steel, offer excellent recyclability at the end of their lifecycle. This characteristic aligns well with circular economy principles and can contribute to a company's sustainability goals. However, the energy-intensive production of metal settlers should be considered in the overall environmental assessment. Plastic mixer settlers, while potentially less energy-intensive to produce, pose challenges in terms of long-term environmental impact. The recyclability of industrial-grade plastics can be limited, and the potential for microplastic pollution is a growing concern. Companies must weigh these factors against their environmental policies and regulatory requirements when making a selection.

Safety Considerations in Handling and Operation

Safety is paramount in any industrial process, and the choice of mixer settler material can have significant implications. Metal mixer settlers, with their robust construction, offer enhanced safety in high-pressure or high-temperature applications. They are less prone to catastrophic failures and can withstand accidental impacts better than their plastic counterparts. However, the weight of metal units necessitates careful handling during installation and maintenance, potentially increasing the risk of workplace injuries. Plastic mixer settlers, being lighter, reduce handling risks but may be more susceptible to damage from impacts or extreme conditions. Their chemical inertness can be a safety advantage when working with highly reactive substances, reducing the risk of unwanted reactions or contamination.

Regulatory Compliance and Industry Standards

The selection of mixer settler materials must also consider regulatory compliance and industry standards. Metal mixer settlers often have a long history of use in various industries, with well-established standards and certifications. This can simplify the process of obtaining regulatory approvals and meeting industry-specific requirements. Plastic mixer settlers, while gaining popularity, may face more scrutiny in certain applications, particularly in food, pharmaceutical, or high-purity chemical production. It's essential to evaluate the specific regulatory landscape of your industry and ensure that the chosen material meets all necessary standards and certifications. Compliance considerations can significantly impact the overall cost-effectiveness of the equipment, as non-compliance can lead to expensive retrofits or replacements.

Conclusion

The choice between metal and plastic mixer settlers for cost-effectiveness is not straightforward and depends on a multitude of factors. Metal settlers offer durability, longevity, and performance advantages, particularly in demanding environments, but come with higher initial costs. Plastic settlers provide cost savings upfront and excellent chemical resistance but may require more frequent replacements. The most cost-effective solution will vary based on specific operational needs, budget constraints, and long-term goals. A thorough analysis of lifecycle costs, performance requirements, and environmental considerations is essential to make an informed decision that balances economic efficiency with operational excellence.

Contact Us

Ready to optimize your extraction processes with the most cost-effective mixer settler solution? Cuiyan Technology offers expert guidance and cutting-edge equipment tailored to your specific needs. Our team can help you navigate the complexities of choosing between metal and plastic mixer settlers, ensuring you get the best value for your investment. Contact us today at wangzhijun@cuiyan-tec.com to discuss your requirements and discover how we can enhance your operational efficiency and bottom line.