Regular Inspection and Cleaning Protocols

Visual Inspections

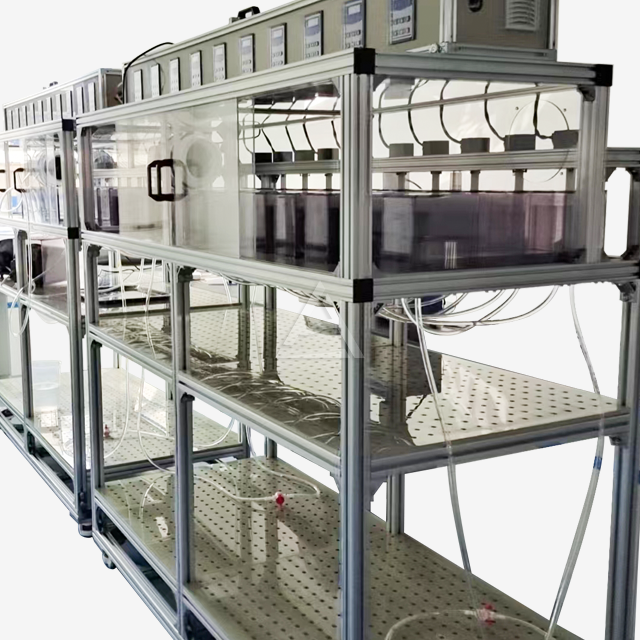

Implementing a routine visual inspection schedule is the foundation of effective mixer settler maintenance. Begin by examining the exterior for any signs of wear, corrosion, or damage. Pay close attention to welds, seams, and connection points, as these areas are prone to stress and potential leakage. For transparent components made of materials like PMMA, check for clarity and scratches that might impede visibility.

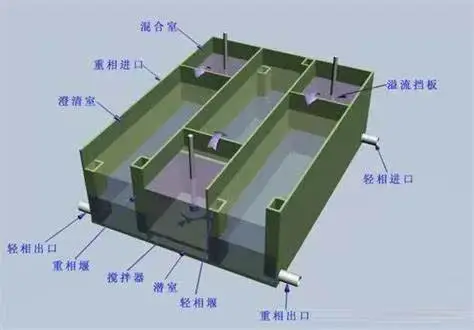

Inspect the interior components, including baffles, weirs, and agitators, for any buildup or damage. Use proper safety equipment and follow lockout/tagout procedures when accessing internal parts. Look for signs of erosion, particularly in areas exposed to high-velocity fluid flow or corrosive chemicals.

Cleaning Techniques

Proper cleaning is essential to prevent contamination and maintain extraction efficiency. After each batch or production run, flush the system with an appropriate cleaning solution. For water-soluble residues, deionized water may suffice. However, for more stubborn deposits, consider using mild detergents or specialized solvents compatible with your mixer settler's material of construction (e.g., PP, PTFE, or SUS316L).

For thorough cleaning, disassemble the mixer settler components as much as possible. Use soft brushes or non-abrasive pads to manually clean surfaces, taking care not to scratch or damage critical parts. Pay special attention to corners, crevices, and hard-to-reach areas where residues tend to accumulate.

Preventive Maintenance Schedule

Develop a comprehensive preventive maintenance schedule tailored to your specific mixer settler model and application. This should include daily quick checks, weekly more detailed inspections, and monthly or quarterly deep cleans and component replacements as needed.

Document all maintenance activities, including observations, actions taken, and any parts replaced. This record-keeping will help you identify patterns, predict potential issues, and optimize your maintenance intervals over time.

Optimizing Operational Parameters

Flow Rate Management

Maintaining appropriate flow rates is crucial for the efficient operation of your mixer settler. Excessive flow can lead to emulsification and poor phase separation, while insufficient flow may result in inadequate mixing and reduced extraction efficiency. Regularly calibrate flow meters and adjust pump settings to ensure optimal performance.

Consider implementing a flow control system that automatically adjusts based on feed composition or process requirements. This can help maintain consistent performance even when input variables change.

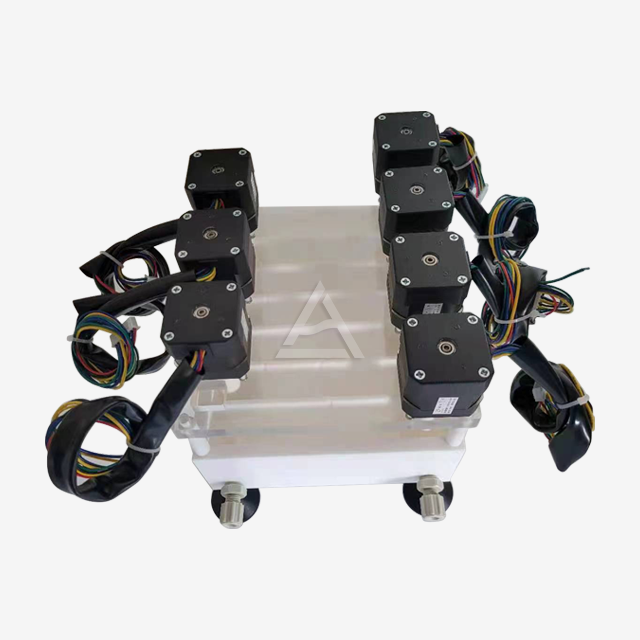

Agitation Speed Optimization

The agitation speed in the mixing stage significantly impacts mass transfer efficiency. Too low a speed may result in inadequate mixing, while excessive agitation can create stable emulsions that are difficult to separate. Use the adjustable agitator speed feature of your mixer settler to find the optimal balance for your specific application.

Conduct periodic tests to verify that the agitation speed remains within the desired range (typically 100-800 RPM). If you notice a decrease in extraction efficiency or separation quality, reassess and adjust the agitation speed as needed.

Interface Level Control

Maintaining the correct interface level between the aqueous and organic phases in the settling compartment is critical for efficient separation. Utilize the adjustable weir system in your mixer settler to fine-tune the interface height. Regular monitoring and adjustment of the interface level can prevent carryover of one phase into another, ensuring high-quality output.

For applications with varying feed compositions or flow rates, consider implementing an automated interface level control system. This can help maintain optimal separation even under changing conditions.

Advanced Maintenance and Troubleshooting

Seal and Gasket Replacement

Seals and gaskets play a crucial role in preventing leaks and maintaining the integrity of your mixer settler. Inspect these components regularly for signs of wear, degradation, or chemical attack. Replace seals and gaskets annually or more frequently if operating in harsh conditions or with particularly aggressive chemicals.

When replacing seals, ensure you use materials compatible with your process chemicals and operating conditions. For example, PTFE seals offer excellent chemical resistance across a wide pH range (1-14) but may not be suitable for all temperature ranges.

Sensor Calibration and Maintenance

If your mixer settler is equipped with integrated sensors for monitoring pH, temperature, or liquid levels, regular calibration is essential. Follow the manufacturer's recommendations for calibration frequency and procedures. Clean sensor probes carefully to remove any buildup that could affect readings.

For pH sensors, use standard buffer solutions to verify and adjust calibration. Temperature sensors may require comparison against a calibrated reference thermometer. Liquid level sensors should be checked for proper activation points and adjusted if necessary.

Troubleshooting Common Issues

Even with diligent maintenance, issues may occasionally arise. Familiarize yourself with common problems and their solutions:

- Poor phase separation: Check for proper interface level, adjust agitation speed, and inspect baffles for damage.

- Reduced extraction efficiency: Verify chemical concentrations, flow rates, and mixing effectiveness. Clean the system to remove any buildup.

- Leaks: Inspect and replace seals, tighten connections, and check for any cracks or damage in the equipment body.

- Uneven flow distribution: Clean distribution plates, check for blockages, and ensure the equipment is properly leveled.

Keep a troubleshooting log to track recurring issues and identify potential root causes. This can help you refine your maintenance practices and improve overall system reliability.

Conclusion

Implementing these best practices for maintaining your mixer settler equipment will significantly enhance its performance, longevity, and reliability. Regular inspections, proper cleaning, optimized operational parameters, and proactive maintenance are key to ensuring your mixer settler continues to deliver high-quality results across various applications. By following this comprehensive guide, you'll minimize downtime, reduce operational costs, and maintain consistent product quality in your extraction processes.

Contact Us

Ready to optimize your mixer settler maintenance? Cuiyan Technology offers expert guidance and top-quality equipment to elevate your extraction processes. Experience the benefits of increased efficiency, reduced downtime, and superior product quality. Contact us today at wangzhijun@cuiyan-tec.com to learn how we can support your specific needs.