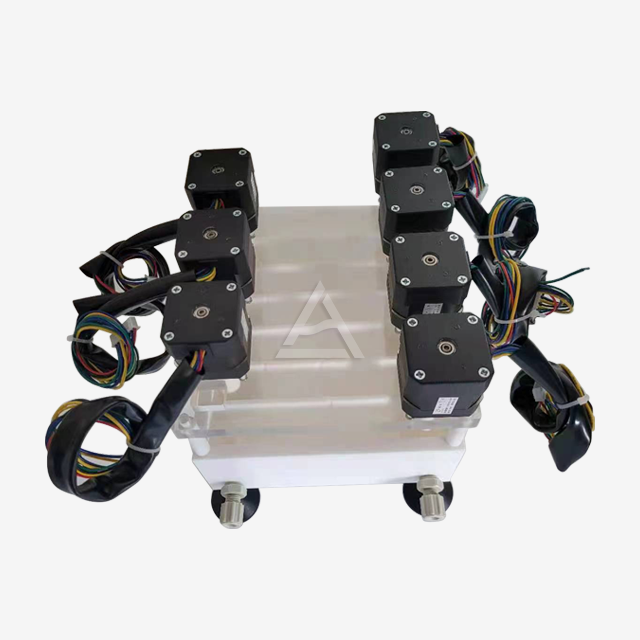

The lab scale mixer settler is an indispensable tool designed for precise and efficient liquid-liquid extraction in both industrial and research contexts. It combines mixing and settling functionalities within a compact framework to facilitate the effective separation of immiscible liquids, ensuring high purity and recovery rates. This equipment is particularly important for sectors requiring GMP-compliant and scalable extraction processes, such as pharmaceuticals, nutraceuticals, and fine chemical production. Its ability to emulate industrial extraction conditions on a smaller scale while maintaining strict control over parameters makes it irreplaceable in process optimization and product development.

Understanding Lab Scale Mixer Settlers

What is a Lab Scale Mixer Settler?

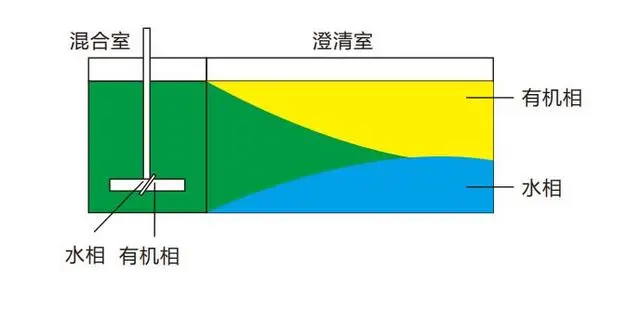

A lab scale mixer settler is a specialized extraction apparatus designed to perform liquid-liquid extractions on a small scale with high precision. The device integrates two primary components: the mixer, where two immiscible liquid phases are thoroughly agitated to enhance mass transfer, and the settler, where the mixed phases separate based on their density differences. Typically, these instruments are engineered with adjustable stages for phase contact and separation, allowing for detailed study and optimization of extraction parameters. Understanding the operational principles and design features of mixer settlers is critical for scientists and engineers seeking the optimal balance between throughput, purity, and scalability.

How Does a Lab Scale Mixer Settler Work?

The operational process of a lab scale mixer settler starts with the careful mixing of two immiscible liquids, often an aqueous and an organic phase, allowing solutes to transfer preferentially from one phase to another. Following mixing, the solution flows into the settling zone, where gravity promotes phase separation. Adjustable features, such as agitator speed and stage quantity, tailor the residence time and phase interface position, maximizing extraction efficiency. Performance evaluation hinges on parameters such as extraction rate, phase purity, and throughput volume. Optimized operational methods significantly impact process yield and product quality.

Many models provide options like temperature control, pH adjustment, and visual monitoring through transparent materials or watch windows, enhancing process control and data acquisition during experiments or production. These elements collectively support applications demanding stringent quality standards.

Applications of Lab Scale Mixer Settlers

Industrial Applications

Lab scale mixer settlers serve as essential tools in numerous industrial processes where precise separation of valuable compounds is mandatory. Chemical processing industries utilize them for specialty chemical extraction, solvent recovery, and wastewater treatment. In pharmaceutical manufacturing, they play a pivotal role in isolating active pharmaceutical ingredients (APIs) with high purity and compliance with GMP regulations. Their modular design supports pilot plant operations and quality control, accommodating diverse volumes and material compatibilities.

Several case studies highlight how labs and small production units employ these systems for metal recovery and electrolyte purification, demonstrating their reliability and cost efficiency at early-stage scale-up or formulation adjustments. Their adaptability to aggressive solvents, coupled with robust construction, positions them as trustworthy assets in controlled industrial settings.

Research and Development

In research and development labs, mixer settlers are invaluable for simulating and optimizing extraction protocols before full-scale manufacturing. Scientists can adjust variables such as shaking speed, phase ratio, temperature, and number of stages, enabling fine-tuning of complex separations critical for natural product extraction, essential oil refinement, or cosmetic ingredient isolation. The devices facilitate rapid experimentation with minimal reagent consumption, providing detailed insights into phase behavior and solute distribution.

Their use in R&D enhances the innovation pipeline, helping researchers develop new formulations or improve existing processes with precision and reproducibility. This contributes to faster time-to-market and reduced resource expenditure.

Advantages of Lab Scale Mixer Settlers

Design and Efficiency

The thoughtful design of modern lab scale mixer settlers focuses on maximizing extraction efficiency while minimizing physical footprint and energy consumption. Compact configurations like the desktop base edition, mobile standard edition, and environmentally friendly high edition cater to diverse laboratory environments, balancing throughput and spatial constraints without sacrificing performance.

They incorporate features like adjustable mixer speed (50–800 RPM), customizable stage numbers, and variable plate thickness (ranging from 5mm to 10mm), which empower users to tailor operations based on their unique extraction profiles. Materials such as PTFE, SUS316L, and transparent PVC contribute to chemical resistance and process observability. Compared to alternative separation techniques like centrifugation or filtration, these mixer settlers deliver superior yields with lower energy inputs, showcasing both economic and environmental advantages.

Performance and Maintenance

Maintaining continuous, high-purity separations requires equipment that is easy to service and durable. Lab scale mixer settlers from Shaanxi Cuiyan Technology feature robust construction with welding, bonding, bending, injection molding, and integral forming production techniques to ensure leak-proof operation and long service life. Their modularity allows quick disassembly for cleaning or component replacement, reducing downtime and operational costs.

Optional devices such as temperature control units, pH adjustment mechanisms, and anti-overflow tanks enhance process stability and safety. Customer testimonials confirm reduced maintenance effort and stable operational performance over extensive usage periods. These benefits address common industry concerns such as contamination risks and equipment reliability.

Comparing Lab Scale Mixer Settlers

Lab Scale Mixer Settler vs Industrial Mixer Settler

Lab scale mixer settlers differ significantly from their industrial counterparts by offering greater flexibility for small-volume, high-precision extraction tasks. While industrial units cater to full-scale continuous operations requiring larger throughput with optimized economies of scale, lab scale systems prioritize adaptability, fine adjustment, and sample conservation.

Cost-wise, lab scale mixer settlers are more accessible for R&D departments or pilot projects, reducing upfront investment and operational complexity. Their modular design allows scaling up by linking multiple units or transitioning seamlessly to pilot or production-scale setups when necessary.

Lab Scale Mixer Settler vs Other Separation Methods

Compared with centrifugation and filtration methods, lab scale mixer settlers provide several distinct benefits. They consume less energy due to gravity-based phase separation, avoid mechanical shear that might degrade delicate compounds, and offer superior control over interfacial phenomena critical in sensitive extractions.

Furthermore, their compatibility with aggressive solvents and ability to integrate auxiliary control systems (temperature, pH) enhances process specificity. In delicate botanical extractions and pharmaceutical APIs, such precision prevents compound degradation and improves overall product quality.

Purchasing Lab Scale Mixer Settlers

Finding the Right Supplier

Procuring high-quality lab scale mixer settlers requires careful consideration of several factors including product quality, customization capabilities, customer support, and industry reputation. Leading suppliers often offer modular solutions tailored to various volumes and materials, alongside technical consultation and after-sales services.

Evaluating supplier credentials across geographic markets such as the US, Europe, and Asia can help position buyers for successful integration. Shaanxi Cuiyan Technology Co., Ltd. stands out by delivering advanced lab-scale equipment with proven performance backed by extensive application experience across sectors like rare earth extraction, battery recycling, and pharmaceutical R&D.

Pricing and Rental Options

Budget considerations play a pivotal role in equipment procurement strategies. Purchasing lab scale mixer settlers entails an upfront investment justified by long-term operational benefits and customization potential. Rental programs can offer flexible access for short-term projects, enabling experiments without major capital expenditure.

Cost-benefit analyses generally favor ownership for entities with ongoing extraction needs, whereas rental suits pilot studies or occasional use. Engaging suppliers with transparent pricing models and maintenance agreements ensures predictable total cost of ownership.

Integrating Lab Scale Mixer Settlers into Your Operations

Company Introduction and Product Services

Shaanxi Cuiyan Technology Co., Ltd., founded in 2012, specializes in R&D, manufacturing, and global supply of extraction equipment, including lab scale mixer settlers. The company leverages over 12 years of industry experience to offer modular, corrosion-resistant systems favored by more than 300 clients worldwide. Their patented technologies - covering automated controls, anti-bubbling innovations, and rapid scalability - address the nuanced requirements of small-scale extraction workflows.

From rare earth purification and lithium battery recycling to pharmaceutical solvent extractions, Shaanxi Cuiyan's offerings streamline integration via customizable configurations, on-site technical support, and training modules. Clients benefit from agile production lines and precision tools that simulate industrial conditions with exceptional fidelity.

Conclusion

Lab scale mixer settlers are pivotal in bridging the gap between laboratory experimentation and industrial-scale extraction, offering compact, efficient, and customizable solutions for diverse applications. Their unparalleled control, high extraction rates, and durable construction address the exacting standards of pharmaceuticals, nutraceuticals, chemical processing, and environmental applications. Trusted manufacturers like Shaanxi Cuiyan Technology Co., Ltd. provide innovative and scalable mixer settlers backed by extensive expertise and patented technologies, facilitating enhanced process development and sustainable production. Embracing these systems can significantly elevate product quality, operational efficiency, and research innovation in your organization.

FAQs

What are the main benefits of using a lab scale mixer settler?

Lab scale mixer settlers deliver efficient, reproducible liquid-liquid separation with minimal operational complexity, supporting both industrial quality control and research settings. Their controllability, customizable stages, and material versatility allow extraction of high-purity compounds while facilitating scale-up prediction.

How do I choose the right lab scale mixer settler for my needs?

Selection depends on your specific application, including solvent compatibility, sample volumes, purity targets, and control features like temperature or pH adjustment. Consider supplier reliability, customization capacity, and integration support to ensure alignment with your R&D or production goals.

Can lab scale mixer settlers be rented?

Yes, many suppliers offer flexible rental options ideal for temporary projects or budget constraints. This allows access to advanced extraction technology without heavy upfront costs and enables evaluation before committing to purchase.

Where to Buy Lab Scale Mixer Settler?

Shaanxi Cuiyan Technology Co., Ltd. stands as a reliable and experienced manufacturer of lab scale mixer settlers with over a decade of industry expertise. Their offerings include configurations such as desktop base editions, mobile standard editions, and environmentally friendly high editions. These products provide customizable features in mixing volume, material selection, and optional functions to suit a wide range of application needs. Prospective buyers seeking quality equipment coupled with professional support are invited to contact us at wangzhijun@cuiyan-tec.com for product details, quotations, and tailored solutions designed to enhance your separation processes with precision and confidence.

References

Seader, J. D., Henley, E. J., & Roper, D. K. (2011). Separation Process Principles. Wiley.

Skoog, D. A., Holler, F. J., & Crouch, S. R. (2018). Principles of Instrumental Analysis. Cengage Learning.

Peters, M. S., Timmerhaus, K. D., & West, R. E. (2003). Plant Design and Economics for Chemical Engineers. McGraw-Hill.

King, C. J. (2000). Separation Processes. McGraw-Hill.

Sharma, S., & Vohra, R. (2019). Advances in Liquid–Liquid Extraction. Chemical Engineering & Technology.

Gupta, A., & Verma, R. (2021). Application of Mixer Settlers in Battery Recycling. Journal of Sustainable Chemistry.