The role of a mixer settler transcends mere mechanical separation - it embodies precision, efficiency, and compliance in chemical compound separation processes. These systems adeptly blend immiscible phases and then allow them to separate under gravity, facilitating high-purity extractions essential across industries such as pharmaceuticals, nutraceuticals, food production, personal care, and industrial chemical manufacturing. By delivering scalable and GMP-compliant separation, mixer settlers underpin the quality and throughput demanded by modern R&D scientists and production managers alike.

Understanding Mixer Settler Principles

How Mixer Settlers Work?

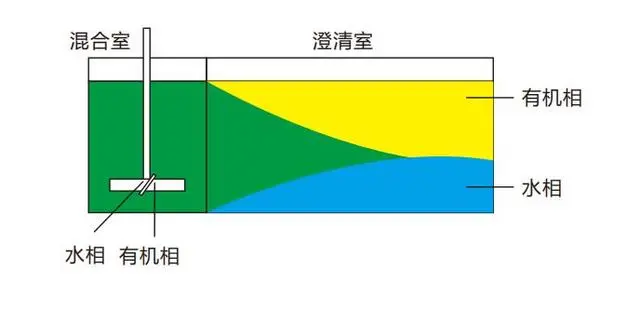

Mixer settlers function through a two-stage process: mixing and settling. During mixing, an agitator thoroughly combines two immiscible liquid phases - commonly organic and aqueous - to promote mass transfer of target compounds. Following mixing, the mixed fluid transitions into the settling zone, where gravity segregates the denser and lighter phases. Adjustable weirs and phase interface controls guide the separation, enabling precise retrieval of purified compounds.

This operating principle balances mechanical agitation with gentle phase separation, preserving delicate bioactive compounds - a crucial aspect for pharmaceutical botanicals and natural flavor extractions. Adjustable parameters, such as agitator speed and stage number, allow customization for diverse feedstocks and processing volumes, ensuring GMP compliance and scalability.

Advantages and Disadvantages

Employing mixer settlers introduces several benefits to chemical separation workflows. Here are the core advantages of this device:

- High Extraction Efficiency: The combination of vigorous mixing followed by controlled settling facilitates superior mass transfer rates, leading to enhanced extraction yields and product purities.

- Operational Simplicity and Low Leakage Risk: Designs featuring seamless welding and robust seals prevent cross-contamination and minimize downtime caused by leaks.

- Customizability: Adjustable mixer-settler stage counts, agitator speeds, and phase interface heights cater to varied process requirements without substantial redesign.

- Cost-Effectiveness: Compared to distillation or centrifugation, mixer settlers consume less energy and require simpler maintenance.

However, there are some limitations to consider. Mixer settlers generally have a larger physical footprint than continuous extraction columns, potentially constraining space in certain facilities. Additionally, the settling step relies on gravity, limiting throughput speeds for highly viscous or emulsified feed streams. Understanding these trade-offs enables process engineers to select the most appropriate separation technology tailored to their operational needs.

Comparing Mixer Settlers with Other Separation Technologies

Mixer Settler vs Extraction Column

Comparing mixer settlers with extraction columns highlights distinct operational paradigms. Extraction columns provide continuous countercurrent contact between phases with a smaller footprint and higher throughput for large-scale production. However, they often involve more complex internals and higher pressure drops, necessitating careful operational control.

Mixer settlers, by contrast, excel in batch or semi-continuous processes where precise phase separation and gentle handling are paramount, such as botanical extracts in pharmaceuticals or delicate flavor compounds. Case studies within nutraceutical manufacturing confirm that mixer settlers achieve comparable or superior purity levels, especially where strict GMP standards and scalability are critical.

Mixer Settler vs Centrifugal Extractor

Centrifugal extractors offer accelerated phase separation via centrifugal forces, minimizing settling time and reducing equipment size. Their high throughput suits large-scale industrial chemical and petrochemical processes. Nevertheless, the mechanical complexity and higher operational costs are notable.

Mixer settlers maintain an edge where solvent integrity and low shear conditions are required - key in cosmetics and personal care formulations where the bioactive components' stability is vital. Efficiency analysis reveals that while centrifugal extractors shorten cycle times, mixer settlers provide better control over phase interface and extraction selectivity, supporting stringent quality demands.

Applications and Design of Mixer Settlers

Key Applications

The versatility of mixer settlers resonates across multiple industries. In rare earth extraction, they enable precise separation of elements such as neodymium and dysprosium, pivotal to clean energy technologies. Lithium battery recycling benefits from mixer settlers' ability to recover lithium and cobalt efficiently, contributing to sustainable resource management.

Nuclear processing leverages these systems for uranium and plutonium purification, ensuring safety and regulatory compliance. Additionally, wastewater treatment utilizes mixer settlers for effective removal of heavy metals like copper and zinc, protecting ecosystems and public health.

Their applications extend equally to food and beverage sectors for preserving natural flavors, and cosmetics for gentle isolation of active ingredients, demonstrating unmatched adaptability.

Design Considerations

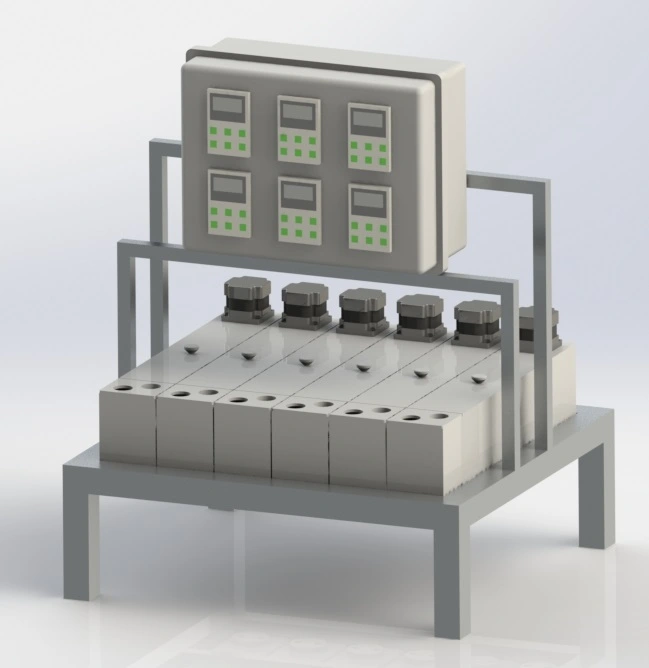

Designing a mixer settler involves careful selection of configuration, materials, and auxiliary features to meet specific operational parameters. Shaanxi Cuiyan Technology Co., Ltd offers three configurations tailored to diverse requirements: desktop base edition, mobile standard edition, and environmentally friendly high edition.

Mixing volumes are customizable between 200mL to 3L (or tailored sizes), enabling process scalability from laboratory R&D to full production. Plate thickness options (5mm to 10mm) and materials - ranging from chemical-resistant PP, PTFE, SUS316L stainless steel to transparent PMMA - ensure compatibility with corrosive, acidic, or alkaline fluids.

Production techniques include welding, bonding, bending, and injection molding to secure structural integrity. Optional functions enhance process control, such as temperature regulation, pH adjustment devices, water-bath jackets, anti-overflow tanks, and observation windows, all contributing to automation and reproducibility.

Procurement Insights for Mixer Settlers

Pricing and Models

Understanding price dynamics involves consideration of configuration choice, volume capacity, material grade, and optional features. Base edition models provide cost-effective solutions for smaller batches, whereas environmentally friendly high editions integrate energy-efficient components and advanced monitoring devices for demanding applications.

Custom models addressing unique process requirements are available, with pricing varying accordingly. Shaanxi Cuiyan's modular design allows buyers to scale capacity and add features incrementally, facilitating budgeted investments aligned with production growth.

Choosing the Right Supplier

Selecting a reliable mixer settler supplier is critical to ensure product quality, technical support, and long-term partnership viability. Shaanxi Cuiyan Technology Co., Ltd stands out due to 37+ engineering experts, 100+ patents, and over a decade of experience in extraction system development.

Their global compliance with ASME, ISO, and REACH standards assures adherence to international quality benchmarks. The company's commitment to customization, zero-leak designs, and post-sale service enhances trust for pharmaceutical and industrial clients with stringent regulatory demands.

Incorporating Mixer Settlers into Your Operations

Maintenance and Operation

Optimizing mixer settler performance requires regular maintenance guided by well-defined protocols. Cleaning after each batch with deionized water prevents cross-contamination and prolongs component life. Annual seal replacement and calibration of agitator speed (100 to 800 RPM) sustain operational precision.

The inclusion of PLC-based sensor integration facilitates real-time monitoring of pH, temperature, and liquid levels, enabling proactive intervention. Following manufacturer-provided operation manuals ensures maximum extraction efficiency and equipment longevity.

Safety and Environmental Impact

Safety features embedded in mixer settler designs reduce risks associated with chemical handling. The zero-leak construction, temperature and pH monitoring, and overflow prevention devices mitigate spill and exposure hazards effectively.

Environmental sustainability benefits from these systems through energy-efficient modular designs, reducing power consumption by 15-20% compared to conventional units. Their applicability in wastewater treatment further reflects contribution to eco-friendly industrial practices.

Conclusion

Mixer settlers play an essential role in achieving rigorous chemical compound separation across diverse industries. Their combination of customizable mixing and settling stages delivers high extraction efficiencies, operational safety, and sustainable energy use. Shaanxi Cuiyan Technology Co., Ltd’s state-of-the-art mixer settlers incorporate advanced materials and modular design to meet escalating industrial standards. Investing in such versatile and reliable equipment can markedly enhance your extraction processes, yielding superior product quality and operational excellence.

FAQs

What are the common issues faced with mixer settlers?

Typical challenges include phase emulsification causing slow settling, seal wear leading to leaks, and fouling on internal surfaces. Choosing high-quality materials like PTFE and employing patented baffle designs help mitigate these issues and enhance phase separation stability.

How do you maintain a mixer settler for optimal performance?

Maintenance involves post-batch cleaning with deionized water, periodic seal and agitator inspections, and calibration to maintain agitator speed and phase interface settings. Integration of real-time sensors enables early detection of operational anomalies.

What innovations are currently being developed in mixer settler technology?

Advances focus on automation with PLC-controlled parameters, materials with enhanced corrosion resistance, energy-efficient modular designs, and integrated sensor arrays for comprehensive process analytics. Additionally, customized configurations for niche applications like lithium battery recycling and nuclear extraction are gaining traction.

Where to Buy Mixer Settlers?

Purchasing a mixer settler that balances precision, compliance, and scalability is pivotal. Shaanxi Cuiyan Technology Co., Ltd stands as a trusted manufacturer and supplier, offering a wide range of configurations from desktop base editions to environmentally friendly high editions. Equipped with an experienced team and comprehensive post-sale support, Shaanxi Cuiyan addresses complex separation challenges with cutting-edge technology. Contact us at wangzhijun@cuiyan-tec.com to discuss your specific requirements and receive customized solutions tailored to your industry’s needs.

References

King, C.J. "Separation Processes." McGraw-Hill, 1980.

Miller, C.A., "Liquid-Liquid Extraction: Fundamentals and Industrial Applications," Wiley-VCH, 2014.

Scott, T.C., and Porter, M.D. “Design and Scale-up of Mixer Settlers,” Industrial & Engineering Chemistry Research, 2006.

Lo, C.C.H., "Modern Extraction Technologies for Pharmaceuticals," Journal of Pharmaceutical Science, 2018.

Peterson, R., "Advanced Separation Techniques in Chemical Engineering," Elsevier, 2017.

Zhang, H., and Liu, W., "Innovative Mixer Settler Designs for Rare Earth Metal Processing," Hydrometallurgy Review, 2020.