Extraction equipment is pivotal in optimizing industrial procedures by precisely separating valuable compounds from raw materials. These systems not only streamline workflows but also ensure compliance with stringent quality standards while boosting productivity. Businesses across pharmaceuticals, food & beverage, cosmetics, and chemical industries increasingly rely on this advanced technology to enhance product purity, operational scalability, and safety. Shaanxi Cuiyan Technology Co., Ltd offers tailored liquid extraction equipment designed to meet such rigorous demands, ensuring high extraction efficiency and customizable configurations for diverse applications.

Understanding Extraction Equipment

What is Extraction Equipment?

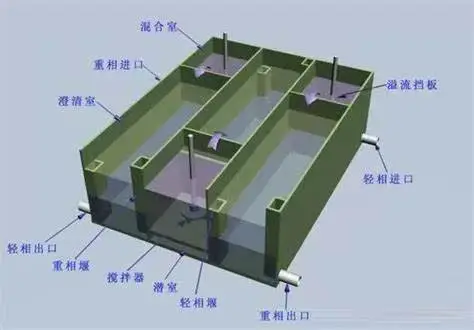

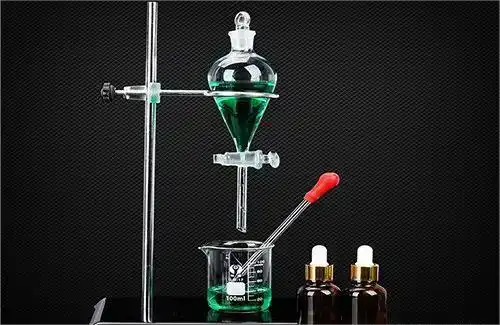

Extraction equipment facilitates the selective isolation of target substances from complex mixtures, forming a foundation for numerous industrial processes. This machinery integrates critical components like precision pumps to deliver fluids consistently, filtration units that ensure clarity and purity, and reactors where controlled chemical reactions enhance separation. Their thoughtful design reduces manual labor and process variability, ultimately promoting operational consistency and accuracy. Visual representations of these components - such as sectional views of mixers or settler tanks - can elucidate their roles in achieving meticulous separation.

Types of Extraction Equipment

The market offers various extraction system models crafted for specific industrial applications:

- Box-type Extraction Tanks: Ideal for batch processes, offering flexibility in research and pilot scales.

-Tubular Extraction Tanks: Suited for continuous operation scenarios, enhancing throughput.

-Centrifugal Extractors: Utilize centrifugal forces to accelerate phase separation, improving efficiency for high-volume tasks.

-Extraction Towers: Provide extensive contact stages for demanding separation requirements in chemical and metallurgical industries.

Recent technological advancements in extraction equipment include environmentally friendly designs emphasizing energy conservation and reduced solvent usage. These innovations contribute to sustainable manufacturing practices without sacrificing performance, vital for food-grade, pharmaceutical, and cosmetic sectors.

Benefits of Using Extraction Equipment

Efficiency and Productivity

Extraction technology substantially enhances operational efficiency by automating critical separation steps. For example, Shaanxi Cuiyan's liquid extraction units deliver over 95% extraction rates due to adjustable mixer-settler stages and precision-controlled agitator speeds. This high level of control optimizes phase contact and separation kinetics, shortening cycle times while preserving sensitive bioactive compounds crucial in nutraceuticals and cosmetics production. Reduced manual handling leads to fewer errors and consistent output, contributing to predictable production timelines and cost savings - essential for large-scale manufacturers aiming to maintain market competitiveness.

Safety and Maintenance

Industrial safety surrounding extraction equipment cannot be overstated. Shaanxi Cuiyan incorporates materials such as PTFE and stainless steel (SUS316L) that resist corrosion and chemical attack, decreasing leak risks and hazards associated with solvent handling. Optional safety features like anti-overflow tanks and real-time monitoring sensors for pH and temperature allow prompt intervention, preventing accidents and equipment damage. Routine maintenance is simplified via modular designs and user-friendly interfaces, reducing downtime and maximizing equipment lifespan, which financially benefits continuous operation facilities.

Comparing Extraction Equipment Options

Extraction Equipment vs Distillation Equipment

Although distillation is a time-tested separation technique, extraction equipment offers superior precision and energy efficiency for specific applications. Extraction excels when dealing with thermally sensitive compounds where heat-induced degradation must be avoided - a common requirement in pharmaceuticals and natural ingredient production. Conversely, distillation remains preferred for volatile compound separation. Extraction machinery generally consumes less energy since it does not rely on prolonged heating, ultimately reducing operational costs and environmental impact while delivering high-purity outputs.

Features and Cost Analysis

Purchasing decisions should weigh key parameters such as:

- Capacity: Options range from laboratory-scale volumes (200ml) to customized industrial sizes (up to 3L and beyond), allowing precise scaling.

- Material Compatibility: FDA-compliant polymers like PP and PVC ensure food-grade safety, while titanium and stainless steel options meet stringent chemical resistance standards.

- Automation Level: Integrations for temperature or pH control facilitate sophisticated process control, justifying initial investment through operational efficiencies.

While upfront costs vary according to customization and capacity, long-term savings emerge from energy-efficient designs, reduced waste, and enhanced product quality. Cost-benefit analyses rooted in these factors support sustainable investment choices.

Purchasing Extraction Equipment

Finding the Right Supplier

Choosing a dependable manufacturer guarantees access to quality products backed by expert support. Shaanxi Cuiyan Technology Co., Ltd stands out due to its extensive experience since 2012 and a specialized team of 37 experts devoted to extraction technology innovation. Delivering solutions to over 300 global clients across sectors highlights its credibility and technical strength. Client testimonials and case studies affirm their commitment to customization and reliable performance, attributes indispensable in industries demanding GMP compliance and precision.

Company Introduction and Product Offerings

Shaanxi Cuiyan Technology Co., Ltd specializes in high-performance liquid extraction equipment designed for industrial, pilot, and research applications. Their solutions include desktop base models, mobile standard units, and eco-friendly editions, addressing needs from laboratory experiments to industrial throughput. Mixing volumes are adaptable, ranging from 200ml to several liters, with options for custom sizes.

Materials used cover a range of polymers and metals - PP, PPH, PVC, transparent PVC, PMMA, PTFE, PEEK, SUS, and Ti - manufactured through welding, bonding, bending, injection molding, and integral forming techniques. This diversity enables precise compatibility with various processing chemistries.

Optional features such as temperature control devices, pH adjustment systems, water-bath jackets, anti-overflow tanks, and watch windows enhance process control and operational convenience. Structural advantages include:

- Robust, leak-free construction minimizing process interruptions

- Adjustable mixer-settler stages and agitator speeds for optimized extraction performance

- Customizable phase interface heights improving separation efficiency

Industries served encompass rare earth and nickel-cobalt extraction, salt lake brine processing, lithium and vanadium battery recycling, copper electroplating waste recovery, nuclear extraction, and biological wastewater treatment.

Conclusion

Leveraging advanced extraction equipment transforms industrial processes by enhancing precision, safety, and scalability. Shaanxi Cuiyan Technology Co., Ltd's customized solutions integrate robust materials, intelligent design, and flexible features to address diverse sector-specific challenges. As industries evolve toward more sustainable and efficient operations, investing in cutting-edge extraction technology becomes imperative to maintaining competitive advantage and ensuring product integrity across pharmaceuticals, nutraceuticals, food, cosmetics, and chemical manufacturing.

FAQs

What are the key benefits of using extraction equipment?

Extraction equipment enhances operational efficiency by reducing manual handling and improving separation precision. It ensures product purity, complies with safety regulations, lowers operational costs through energy-saving designs, and accommodates scalable production volumes tailored to industry needs.

How does extraction equipment compare to traditional methods?

Extraction technology offers greater energy efficiency and precision than many conventional separation techniques like distillation. It protects sensitive compounds from thermal degradation and can be customized to deliver higher throughput with reduced environmental impact.

What should I consider when choosing extraction equipment?

Selection criteria include the desired processing capacity, compatibility with raw material chemistries, automation level, compliance with industry standards, ease of maintenance, and supplier support. Customization capabilities and energy efficiency also critically influence long-term cost-effectiveness.

Where to Buy Extraction Equipment?

Shaanxi Cuiyan Technology Co., Ltd is a trusted name in manufacturing and supplying liquid extraction equipment tailored to complex industrial applications. Interested businesses can explore a broad spectrum of equipment ranging from desktop to environmentally friendly editions, meeting diverse volume and customization demands. For inquiries or detailed quotations, contact us at wangzhijun@cuiyan-tec.com. Our dedicated team stands ready to support your advancement in industrial extraction processes.

References

Geankoplis, C.J. "Transport Processes and Separation Process Principles," Fourth Edition, 2003.

Miller, J.D., et al., "Extraction Technologies in the Processing of Natural Products," Journal of Industrial Chemistry, 2019.

Dutta, P.K., et al., "Advances in Extraction Processes," Separation and Purification Technology, 2021.

Klein, M. & Hermans, L., "Modern Solvent Extraction Techniques," Chemical Engineering Progress, 2020.

Smith, R., "Chemical Process Design and Integration," John Wiley & Sons, 2016.

Brown, P. & Wilson, G., "Sustainable Extraction Methods in the Food Industry," Food Science and Technology, 2018.