Lithium Battery Industry Mixer Settler

Cooperation solution: labor+material contracting,labor-ony contracting

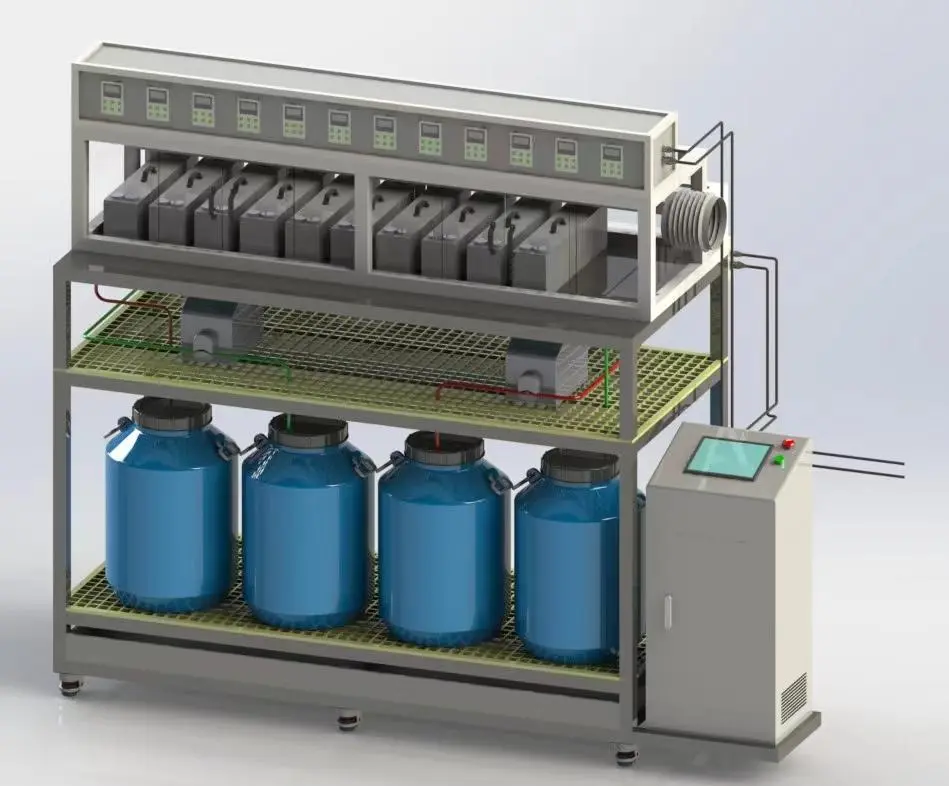

Mixing volumn: 100L,200L,300L,500L,800L,1000L or customized

Plate thickness:12mm,15mm,20mm,25mm,30mm

Material: PP,PPH,PVC,transparent PVC

Production process: welding

Optional function: temperature control device,pH adjustment device,anti-overflow tank device

Advantages: high extraction rate,perfect separation effect;No leakage risk, easy operation,sturdy and beautiful shape;Adjustable agitator speed,adjustable phase interface height

Application: rare earth extraction;nickel cobalt extraction;rubidium cesium extraction;salt lake brine extraction;nuclear extraction;lithium battery recycling;vanadium battery recycling;copper electroplate recycling;biological wastewater recycling

- Product Description

Shaanxi Cuiyan: Your Trusted Lithium Battery Industry Mixer Settler Manufacturer & Supplier

For over a decade, Shaanxi Cuiyan Technology Co., Ltd has delivered cutting-edge lithium battery industry mixer settlers to global clients. With 300+ projects and 10,000+ equipment stages sold, our modular, corrosion-resistant systems optimize extraction efficiency for rare earth, salt lake brine, and battery recycling applications.

Lithium Battery Industry Mixer Settler Description

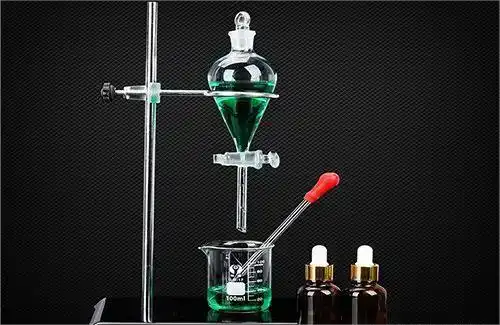

Our lithium battery industry mixer settler enables precise liquid-liquid separation, critical for producing high-purity lithium compounds. Designed for scalability, it integrates seamlessly into lab, pilot, or industrial setups.

Specifications

| Specifications | Details |

|---|---|

| Mixing Volume | 100L, 200L, 300L, 500L, 800L, 1000L (Customizable) |

| Plate Thickness | 12mm, 15mm, 20mm, 25mm, 30mm |

| Material | PP, PPH, PVC, Transparent PVC |

| Production Process | Welding |

| Optional Functions | Temperature Control, pH Adjustment, Anti-Overflow Tank |

Why Choose Our Lithium Battery Industry Mixer Settler?

- ✅ 95%+ Extraction Efficiency: Perfect phase separation for high-purity lithium.

- ✅ Corrosion Resistance: PPH and PVC materials withstand harsh chemicals.

- ✅ Modular Design: Rapid installation and capacity expansion.

- ✅ Customization: Add sensors (pH, temperature) or tailored mixing-clarification tanks.

- ✅ Energy-Saving: Low maintenance costs and 20% reduced energy consumption.

Material & Processing Method

Built with PPH (high-density polypropylene) for extreme durability, our mixer settlers use automated welding to ensure leak-free operation. Transparent PVC models allow real-time process monitoring.

Key Functions

- Adjustable agitator speed for optimized mixing.

- One-step tank filling/emptying to minimize downtime.

- Anti-bubbling technology for stable operation.

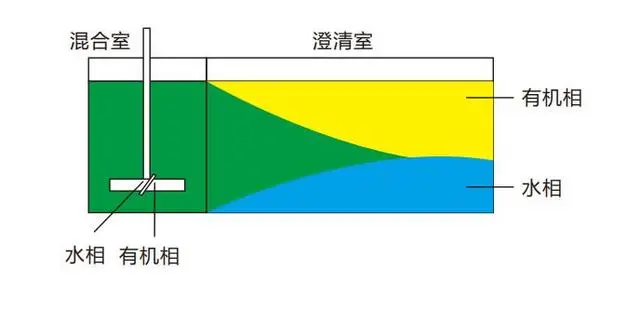

How It Works

- Mixing Stage: Agitators blend solutions to transfer lithium ions.

- Settling Stage: Immiscible phases separate by density.

- Automated Control: Sensors maintain ideal pH and temperature.

Physical Display

Shown here are actual lithium battery industry mixer settler. View the clear photos to better understand their design and features. Feel free to contact us for more information.

User Guide

- Installation

Our installation process is designed to be efficient and minimally disruptive to your operations. Installation typically takes between 2 - 5 days. Skilled technicians begin by assessing your existing production line. They then carefully bolt the new modules into place, ensuring a secure fit. Using high - quality bolts and following strict alignment procedures, they connect each module precisely. This seamless integration with your existing setup allows for a quick transition, minimizing downtime and getting your enhanced system up and running as soon as possible. - Calibration

Calibration is a crucial step in optimizing the performance of the system. Operators use the control panel to set the agitator speed, which can be adjusted according to the viscosity and nature of the substances being processed. Additionally, the phase interface height is calibrated. This is essential, especially in processes involving the separation of immiscible phases. By fine - tuning these parameters, the system achieves maximum efficiency, whether it's in a chemical extraction or a liquid - liquid separation application. - Maintenance

Regular maintenance is key to the long - term reliability of the equipment. Every month, trained personnel conduct comprehensive checks. They inspect moving parts for signs of wear, such as bearings and seals, as excessive wear can lead to mechanical failures. Simultaneously, they verify the accuracy of sensors, which monitor variables like temperature, pressure, and flow. Ensuring sensor accuracy guarantees that the system receives and responds to real - time data correctly, maintaining optimal performance over time.

Application Areas

- Salt Lake Brine Extraction: Efficiently process high magnesium-lithium ratios.

- Battery Recycling: Recover lithium, cobalt, and nickel from spent batteries.

- Rare Earth Purification: Achieve >99% purity for EV battery materials.

Packaging & Transportation

Crates with shock-absorbent foam ensure safe global delivery.

After-Sales Service

24/7 remote support and local spare parts hubs.

Qualification Certification

ISO 9001, ISO 14001, and 12+ national patents.

FAQ

Q: Can you customize mixer settlers for high-altitude salt lakes?

A: Yes! Our designs adapt to low-pressure environments.

Q: What's the lead time for 500L models?

A: 60–90 days, including factory testing.

Q: Do you provide automation integration?

A: We offer PLC or IoT control systems.

Q: How to reduce maintenance costs?

A: Use our self-lubricating agitators and modular replacements.

Q: Are your materials RoHS-compliant?

A: All components meet EU and US standards.

Contact Us

For more information about our lithium battery industry mixer settler, including pricing, customization options, and bulk orders, please feel free to reach out to us:

📩 Email: wangzhijun@cuiyan-tec.com

VIEW MORECounter Current Extractor

VIEW MORECounter Current Extractor VIEW MOREMixer Settler Cascade

VIEW MOREMixer Settler Cascade VIEW MORERare Earth Industry Mixer Settler

VIEW MORERare Earth Industry Mixer Settler VIEW MOREVanadium Battery Industry Mixer Settler

VIEW MOREVanadium Battery Industry Mixer Settler VIEW MOREMicro Liquid Liquid Extractor

VIEW MOREMicro Liquid Liquid Extractor VIEW MOREContinuous Liquid Liquid Extraction Equipment

VIEW MOREContinuous Liquid Liquid Extraction Equipment VIEW MORELiquid Liquid Extraction Industrial Equipment

VIEW MORELiquid Liquid Extraction Industrial Equipment VIEW MOREPVC Mixer Settler

VIEW MOREPVC Mixer Settler