Choosing the right mixer settler for your industrial application is essential to ensure high-efficiency liquid-liquid extraction, seamless phase separation, and operational reliability. A mixer settler combines a mixing chamber with a settling tank, enabling the thorough contact of immiscible phases such as organic solvents and aqueous solutions followed by gentle settling to separate components based on their solubility differences. Selecting a system tailored to your process demands - considering factors like capacity, material compatibility, and overall precision - will optimize your extraction yield while safeguarding product purity and compliance with industry standards. Understanding the nuances of mixer settlers is critical for professionals in pharmaceuticals, food and beverage, cosmetics, and chemical sectors seeking scalable, GMP-compliant, and robust extraction solutions.

Understanding Mixer Settlers

What is a Mixer Settler?

A mixer settler is vital industrial equipment designed for liquid-liquid extraction processes, allowing the partitioning of chemical species into different liquid phases based on their solubility or affinity to solvents. This apparatus combines a mixer, where two immiscible liquids are intensively blended to foster mass transfer, with a settler section, where these phases gently separate due to density differences. Industries such as chemical processing, pharmaceuticals, and metallurgy leverage mixer settlers to achieve purity standards and optimize production throughput. The device's adaptability to controlled mixing and settling makes it indispensable for processes involving botanical extracts, essential oils, and specialty chemical purification - providing efficient, scalable, and clean separation protocols aligned with evolving regulatory requirements.

How Does a Mixer Settler Work?

The operational core of a mixer settler involves a two-stage sequence: mixing and settling. Initially, the agitator blends two immiscible phases, typically aqueous and organic solvents, ensuring uniform contact and mass transfer. This thorough mixing promotes the transfer of target compounds from one phase to another effectively. Following mixing, the liquids enter the settling stage, where gravity facilitates phase separation within a clarifier compartment equipped with adjustable baffles or weirs. Control over parameters such as agitator speed, the height of the phase interface, and the number of extraction stages allows process optimization for different feedstock and solvent systems. Diagrams typically illustrate this flow, showing continuous or batch flow patterns enhancing operability for industrial processes ranging from rare earth extraction to biological wastewater treatment.

Comparing Mixer Settlers with Other Separation Methods

Mixer Settler vs. Extraction Column

When assessing mixer settlers against extraction columns, throughput and separation efficiency are pivotal. Mixer settlers excel in handling larger volumetric flows with excellent phase disengagement, perfect for batch or continuous solvent extraction requiring precise control over residence time and gentle liquid interfaces. Extraction columns, such as pulsed or packed variants, offer higher interfacial areas conducive to mass transfer but often at the expense of more complex maintenance and susceptibility to flooding under varying loads. Therefore, for industries prioritizing scalability, GMP compliance, and robust phase clarity - like nutraceuticals and cosmetics - mixer settlers provide a favorable balance of operational flexibility and product integrity.

Mixer Settler vs. Centrifugal Extractor

Centrifugal extractors use rotational force to accelerate phase separation, achieving rapid throughput and compact footprints. However, the intense shear forces may compromise sensitive bioactive compounds found in natural extracts or delicate food-grade materials. Mixer settlers, with their gentle agitation and gravity-based settling, mitigate risks of molecular degradation, making them ideal for applications like essential oils, natural colorants, and perfumery. Although centrifugal units can handle continuous high-volume streams, the lower energy consumption and customizable mixing parameters of mixer settlers favor environments where extraction precision and chemical stability are paramount. Selecting between these modalities necessitates evaluating process specifics such as material sensitivity, output volume, and solvent recycle requirements.

Evaluating Mixer Settler Suppliers

Top Mixer Settler Manufacturers

Securing a reliable supplier lays the foundation for effective long-term extraction operations. Leading manufacturers distinguish themselves through extensive technical expertise, adherence to quality norms such as ASME, ISO, and REACH, and their ability to deliver customizable mixer settlers tailored for complex needs including rare earths and nuclear material extraction. Manufacturer reputations often hinge on their innovation capacity, patent portfolios, and customer testimonials. For example, Shaanxi Cuiyan Technology Co., Ltd stands out by integrating modular automation, corrosion-resistant alloys like SUS316L and PTFE, and intelligent sensor interfaces, thereby fostering process control precision and operational safety. An established brand ensures technical support, warranty services, and seamless integration into existing production lines, critical factors when scaling extraction systems across global markets.

Custom and Used Mixer Settler Options

Exploring custom mixer settler designs enables companies to align equipment with unique process variables - from mixing volumes (200 ml up to 3L or larger) to optional functionalities such as temperature control and pH adjustment devices. Customization ensures adaptability to a wide pH range (1-14) and various chemical media, bridging gaps that off-the-shelf units cannot. Conversely, purchasing used equipment may appeal for cost savings but demands rigorous inspection for wear, material compatibility, and technological obsolescence. Ensuring welding integrity and seal condition is paramount to avoid contamination or leaks, especially in high-purity applications. Weighing custom solutions' upfront investment against long-term process gains can guide decision-makers toward optimal value solutions.

Technical Support and Maintenance

Mixer Settler Maintenance

Operational continuity of mixer settlers depends on routine maintenance practices tailored to the extraction context. Periodic checks involve inspecting agitator functionality, verifying seals and welds for integrity, and monitoring wear on plates or baffles. Troubleshooting sediment buildup or leaks before they escalate mitigates costly downtime. A structured maintenance schedule, including annual seal replacements and cleaning with deionized water, preserves extraction efficiency and equipment longevity. Additionally, integrating sensor technology to continuously monitor pH and temperature aids in preemptive diagnostics, ensuring product consistency and compliance with GMP and environmental standards across pharmaceuticals and nutraceuticals.

Installation and Operation Guide

Proper assembly and commissioning are crucial for optimizing mixer settler performance. Equipment can be configured vertically or horizontally depending on spatial constraints and process design. Calibration involves setting agitator speeds within 100 to 800 RPM and adjusting phase interface heights through user-friendly touchscreen controls, enabling personalized extraction workflows. Operating guidelines emphasize gradual phase loading to prevent turbulence and enable stable phase interfaces. Comprehensive operator training and detailed manuals ensure safe and efficient handling, minimizing human error during daily operations. Such rigor is essential in sectors that demand high extraction purity such as nuclear material refinement or lithium cobalt battery recycling.

Shaanxi Cuiyan Technology Co., Ltd: Leading Provider of Mixer Settlers

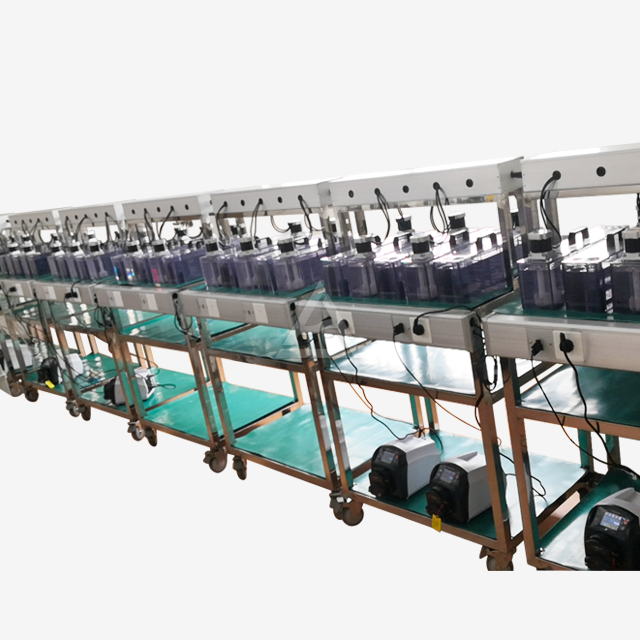

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has pioneered mixer settler solutions for a broad spectrum of industrial sectors including rare earth element recovery, lithium battery recycling, and nuclear fuel processing. Our dedicated team of over 37 experts and a portfolio encompassing more than 100 patents reflect our commitment to innovation and quality. Our mixer settlers feature customizable stage counts, adjustable agitator speeds, and zero-leak designs employing PTFE seals and precision welding. Modular engineering not only reduces energy consumption by 15-20% but also ensures compliance with global standards such as ASME and ISO. We integrate sensor technologies for continuous monitoring enabling smarter process control. Our materials selection ranges from corrosion-resistant SUS316L and titanium to transparent PMMA for real-time mixing observation. These strengths position Shaanxi Cuiyan as a trusted partner for complex, scalable extraction challenges across the Americas.

Conclusion

Selecting the right mixer settler demands careful assessment of your industry-specific needs alongside equipment capabilities. Prioritize systems that combine high extraction efficiency, customizable controls, and compliance with stringent quality standards. Shaanxi Cuiyan Technology offers designs that meet these exacting demands, backed by reliable support and continuous innovation. Incorporating their mixer settlers into your processes ensures enhanced product purity, operational safety, and scalability for future growth.

FAQs

What are the main advantages of using a mixer settler?

Mixer settlers offer high efficiency in separating immiscible liquid phases, allowing scalability and customization for varied applications. They provide gentle mixing to preserve sensitive compounds, improve throughput, and minimize contamination risks with advanced sealing technologies.

How do I determine the best mixer settler for my application?

Consider your process volume, chemical compatibility, regulatory needs, and material sensitivity. Evaluate optional features such as temperature control, pH adjustment, and modularity. Engaging with suppliers who offer custom configurations ensures the best alignment with your operational requirements.

What should I consider when evaluating mixer settler suppliers?

Look for proven expertise, certifications (like ASME and ISO), technological innovation, robust after-sales support, and flexibility in production and design. Reviews and case studies from industries similar to yours provide valuable insight into supplier reliability and product performance.

Where to Buy Mixer Settler?

For industrial sectors seeking sophisticated mixer settler solutions, Shaanxi Cuiyan Technology Co., Ltd stands as a leading manufacturer with extensive expertise and advanced product configurations. Our company offers options ranging from desktop base editions to environmentally friendly high editions with fully customizable mixing volumes and materials to suit diverse extraction tasks. To discuss how our mixer settlers can elevate your production efficiency and compliance, please contact us at wangzhijun@cuiyan-tec.com. Our team is ready to provide expert consultation and bespoke system designs to match your exact process demands.

References

King, A.D., & Lester, E.Y. (2018). Advanced Solvent Extraction Techniques in Industrial Chemistry. Journal of Separation Science and Technology.

Jones, M.R., & Patel, S. (2020). Scaling Mixer Settlers for Rare Earth Mining Applications: Technical Advances and Challenges. Industrial Mineral Processing Reports.

Mitchell, H.J., et al. (2019). Environmental Compliance and Process Optimization in Battery Recycling Using Mixer Settler Systems. Sustainable Metallurgy Perspectives.

Schneider, K., & Carlson, B. (2021). A Comparative Analysis of Extraction Technologies in Nuclear Materials Processing. Nuclear Engineering Review.

Lee, J.T. & Chen, Y. (2017). Mixer Settler Maintenance Protocols for Continuous Pharmaceutical Extract Purification. International Journal of Pharmaceutical Engineering.

Garcia, L., & Thomas, D. (2022). Innovations in Mixer Settler Design for the Food and Beverage Industry. Journal of Food Process Engineering.