Understanding Mixer Settler Technology

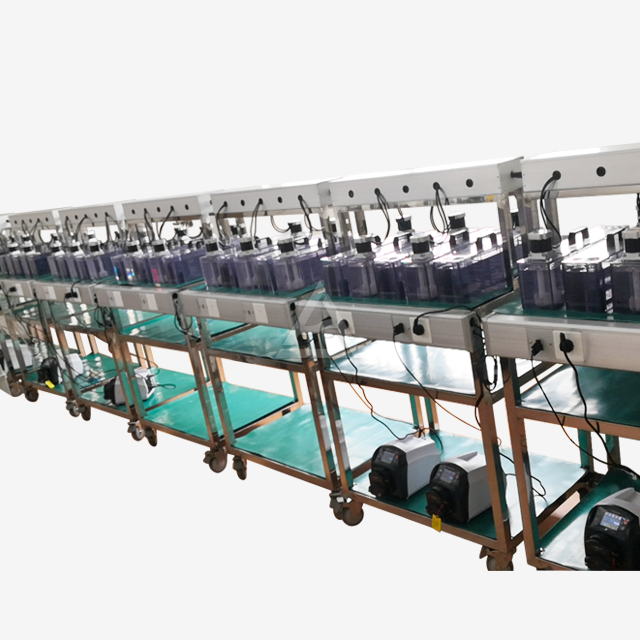

Principles of Operation

Mixer settlers operate on a simple yet powerful principle: controlled mixing followed by gravity-driven separation. In the mixing chamber, two immiscible liquids are vigorously agitated, promoting mass transfer between phases. This process allows desired compounds to migrate from one liquid to another based on their solubility characteristics. Following the mixing stage, the combined liquids flow into a settling chamber where gravity takes over. Here, the lighter phase rises while the heavier phase sinks, creating a clear interface between the two liquids.

Key Components

A typical mixer settler unit consists of several crucial components. The mixing chamber houses an agitator, often a turbine-style impeller, which ensures thorough blending of the liquids. Baffles within the chamber prevent vortex formation and enhance mixing efficiency. The settling chamber features carefully designed weirs and overflow ports to maintain optimal phase separation. Some advanced models incorporate sensors for real-time monitoring of pH, temperature, and interface levels, allowing for precise process control.

Customization Options

One of the greatest strengths of mixer settler technology lies in its adaptability. Units can be tailored to meet specific process requirements, with options including: - Volume capacities ranging from 200ml to 3L or custom sizes - Material choices such as PP, PVC, PMMA, or corrosion-resistant alloys - Temperature control devices for heat-sensitive applications - pH adjustment mechanisms for optimizing extraction conditions - Anti-overflow safeguards to prevent spills and contamination This flexibility allows industries to fine-tune their purification processes for maximum efficiency and product quality.

Applications Across Industries

Rare Earth Element Extraction

In the realm of rare earth element (REE) extraction, mixer settlers play a pivotal role. These devices excel at separating individual REEs like neodymium and dysprosium from complex ore concentrates. The multi-stage nature of mixer settler systems allows for sequential extraction steps, each optimized for specific elemental separation. This capability is crucial in producing high-purity REE compounds essential for advanced magnets, electronics, and green energy technologies.

Battery Material Recycling

As the electric vehicle market expands, so does the need for efficient battery recycling processes. Mixer settlers are at the forefront of this challenge, enabling the recovery of valuable materials like lithium and cobalt from spent batteries. The precise control over mixing intensity and settling time allows for selective extraction of these elements from complex battery slurries. By implementing mixer settler technology, recycling facilities can achieve higher recovery rates and purer end products, contributing to a more sustainable battery supply chain.

Nuclear Fuel Processing

In the nuclear industry, mixer settlers find critical applications in the separation of uranium and plutonium. The ability to handle radioactive materials safely while achieving high-purity separations makes these devices indispensable in nuclear fuel reprocessing. Multiple extraction stages can be linked in series, allowing for precise control over the separation of different isotopes and nuclear materials. This level of control is essential for both energy production and nuclear non-proliferation efforts.

Advantages and Future Developments

Efficiency Gains

Mixer settler technology offers significant advantages over traditional separation methods. The combination of intense mixing and controlled settling results in higher extraction rates and cleaner phase separation. This efficiency translates to reduced processing time, lower energy consumption, and minimized use of extraction solvents. For example, some industries report up to 20% reduction in power usage compared to conventional extraction methods when using optimized mixer settler systems.

Scalability and Modularity

One of the key strengths of mixer settler technology is its scalability. Systems can be easily scaled up or down by adding or removing stages, allowing companies to adapt their processes as production needs change. This modularity also facilitates maintenance and upgrades, as individual units can be serviced or replaced without shutting down the entire production line. The ability to reconfigure extraction processes quickly provides a significant competitive advantage in fast-evolving industries.

Emerging Innovations

The future of mixer settler technology looks promising, with several innovations on the horizon. Researchers are exploring advanced materials that offer superior chemical resistance and longer operational lifespans. Integration of artificial intelligence and machine learning algorithms is enabling predictive maintenance and real-time optimization of extraction parameters. Additionally, miniaturized mixer settler designs are opening up new possibilities for point-of-use purification in fields like pharmaceuticals and specialty chemicals production.

Conclusion

Mixer settler technologies have emerged as a cornerstone of efficient purification processes across diverse industries. Their ability to provide precise control over liquid-liquid extraction, coupled with scalability and adaptability, makes them invaluable in applications ranging from rare earth element purification to nuclear fuel processing. As industries continue to seek more sustainable and cost-effective solutions, the role of mixer settlers in advancing purification technologies is set to grow. With ongoing innovations in materials, design, and process control, these versatile systems will undoubtedly play a crucial role in shaping the future of industrial separation and purification processes.

Contact Us

Ready to revolutionize your purification processes? Cuiyan Technology offers cutting-edge mixer settler solutions tailored to your specific needs. Experience the benefits of enhanced efficiency, reduced costs, and superior product quality. Contact us today at wangzhijun@cuiyan-tec.com to explore how our advanced extraction technologies can transform your operations.