The Fundamentals of Mixer Settler Technology

Design and Components

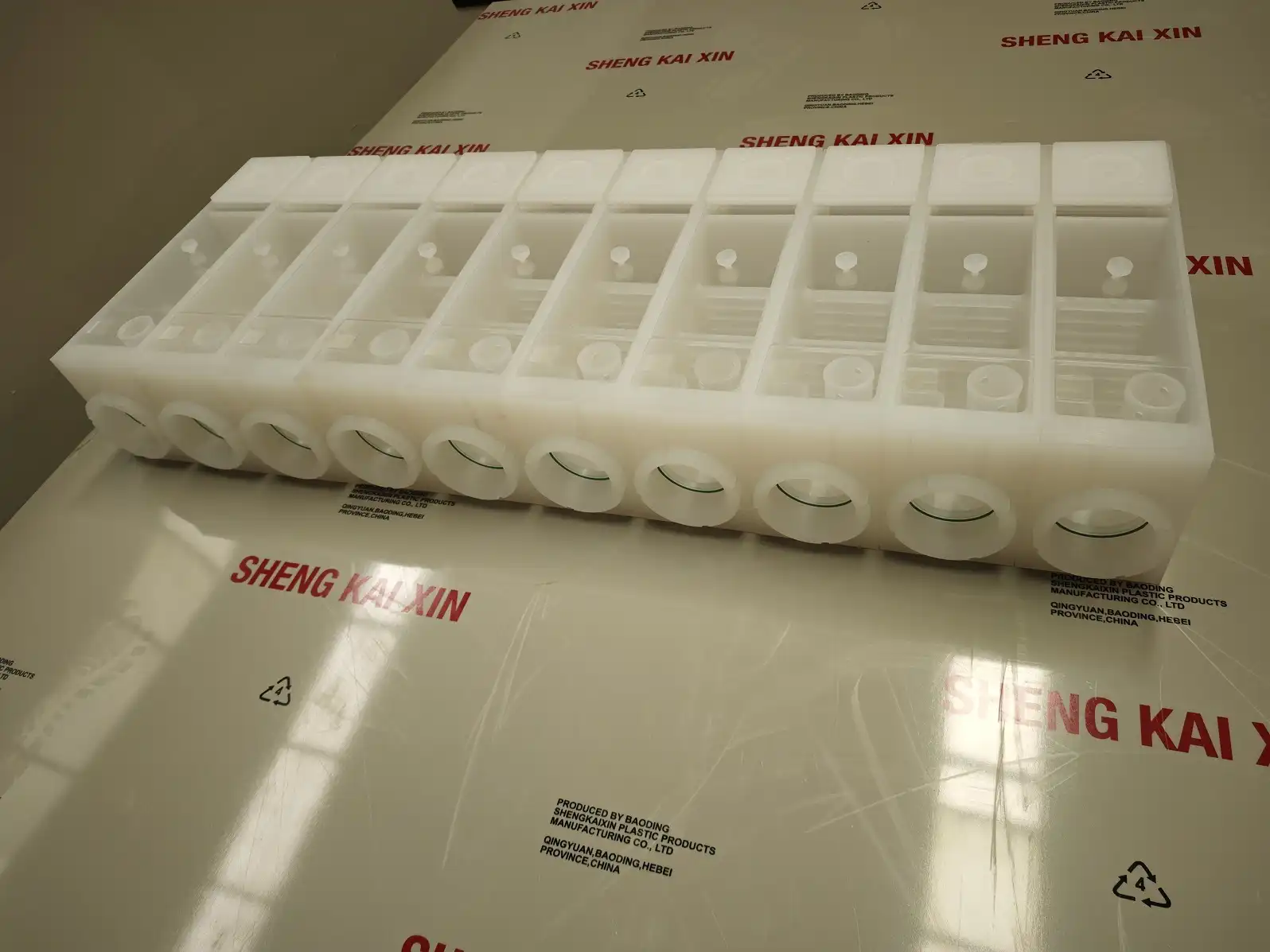

Mixer settlers consist of two primary sections: the mixing chamber and the settling zone. The mixing chamber houses an agitator that blends immiscible phases, typically organic and aqueous solutions. This vigorous mixing promotes mass transfer between the phases. The settling zone, separated by baffles, allows gravity to separate the mixed phases. Adjustable weirs control the interface height, ensuring optimal phase separation.

Key components include:

- Agitator: Controls mixing intensity (100-800 RPM)

- Baffles: Guide flow and prevent short-circuiting

- Weirs: Adjust phase interface height

- Inlet/outlet ports: Manage continuous flow

Material Selection

The choice of materials is crucial for mixer settler performance and longevity. Options include:

- PP, PPH, PVC: For general applications

- PTFE, PEEK: High chemical resistance

- SUS316L, Titanium: Corrosion-resistant for harsh environments

- PMMA: Transparent for process monitoring

Material selection depends on factors like chemical compatibility, temperature requirements, and mechanical stress. For instance, SUS316L and PTFE can handle media with pH ranges from 1 to 14, making them suitable for highly acidic or alkaline processes.

Operational Principles

Mixer settlers operate on a continuous flow principle, allowing for multi-step extraction in a compact setup. The process involves:

- Mixing: Immiscible phases are blended for mass transfer

- Settling: Gravity separates phases in the clarifier zone

- Continuous flow: Solutions move through multiple stages for thorough extraction

Advanced features like patented baffle designs prevent bubbling, ensuring stable phase separation. PLC integration allows real-time monitoring of critical parameters such as pH, temperature, and liquid levels, enabling precise process control.

Advantages of Mixer Settlers in Solvent Extraction

Enhanced Extraction Efficiency

Mixer settlers significantly boost extraction rates compared to traditional methods. The controlled agitation in the mixing chamber maximizes interfacial area between phases, promoting rapid mass transfer. This results in higher extraction yields in shorter processing times. For instance, in rare earth element extraction, mixer settlers can achieve over 99% recovery rates for elements like neodymium and dysprosium, crucial for high-tech applications.

The modular design allows for easy adjustment of stage numbers, enabling multi-step extractions within a single, compact unit. This flexibility is particularly beneficial in complex separations, such as nuclear material processing or isotope extraction, where high purity is paramount.

Precise Process Control

One of the key advantages of mixer settlers is the level of control they offer over the extraction process. Operators can fine-tune various parameters:

- Agitation speed: Adjustable from 100 to 800 RPM to optimize mixing intensity

- Phase interface height: Controlled by adjustable weirs for optimal separation

- Flow rates: Managed via inlet/outlet ports for consistent processing

This precise control enables processors to adapt to varying feed compositions or product specifications quickly. In applications like lithium battery recycling or vanadium battery processing, where feed composition can vary, this adaptability is crucial for maintaining high recovery rates and product purity.

Environmental and Economic Benefits

Mixer settlers offer significant environmental and economic advantages:

- Energy Efficiency: Modular design reduces power consumption by 15-20% compared to traditional extraction methods

- Reduced Solvent Usage: Efficient mixing and separation minimize solvent losses

- Compact Footprint: Vertical or horizontal configuration options save valuable plant space

- Low Maintenance: Robust construction and simple design reduce downtime and maintenance costs

These benefits translate to lower operational costs and reduced environmental impact. For example, in copper electroplate recycling, mixer settlers can significantly reduce chemical consumption and wastewater generation, aligning with increasingly stringent environmental regulations.

Applications Across Industries

Rare Earth Element Extraction

Mixer settlers play a crucial role in the extraction and purification of rare earth elements (REEs) like neodymium and dysprosium. The process typically involves:

- Leaching: REEs are dissolved from ore concentrates

- Solvent Extraction: Mixer settlers separate individual REEs using specific organic extractants

- Stripping: Purified REEs are recovered from the organic phase

- Precipitation: Final products are produced as oxides or carbonates

The multi-stage capability of mixer settlers allows for high-purity separation, crucial for applications in permanent magnets, lasers, and other high-tech products. The ability to handle corrosive solutions and precise control over extraction parameters make mixer settlers ideal for this challenging separation process.

Nuclear Material Processing

In the nuclear industry, mixer settlers are essential for uranium and plutonium separation. The PUREX (Plutonium Uranium Redox EXtraction) process, a standard in nuclear fuel reprocessing, relies heavily on mixer settler technology. Key features that make mixer settlers suitable for this application include:

- Radiation-resistant materials (e.g., PTFE, special grades of stainless steel)

- Ability to handle highly acidic solutions

- Precise control over extraction parameters for high-purity separation

- Modular design allowing for remote operation and maintenance

The use of mixer settlers in nuclear processing ensures efficient recovery of fissile materials while minimizing waste generation, contributing to the sustainability of nuclear power generation.

Wastewater Treatment and Metal Recovery

Mixer settlers are increasingly used in wastewater treatment, particularly for heavy metal removal and recovery. Applications include:

- Copper and zinc removal from industrial effluents

- Recovery of precious metals from electronic waste

- Treatment of acid mine drainage

The process typically involves:

- pH adjustment of the wastewater

- Addition of specific extractants in the mixer settler

- Multi-stage extraction to achieve required purity

- Stripping of metals for recovery or safe disposal

Mixer settlers' ability to handle large volumes continuously, coupled with their high extraction efficiency, makes them an effective solution for meeting stringent environmental regulations while recovering valuable resources.

Conclusion

Mixer settlers have emerged as a game-changing technology in solvent extraction processes, offering unparalleled efficiency, control, and versatility. Their ability to enhance extraction rates, provide precise process management, and adapt to diverse applications makes them invaluable across industries. From rare earth element purification to nuclear material processing and wastewater treatment, mixer settlers are setting new standards in separation technology. As industries continue to seek more efficient, environmentally friendly, and cost-effective solutions, the role of mixer settlers in chemical processing is set to grow, driving innovation and sustainability in extraction processes worldwide.

Contact Us

Ready to revolutionize your extraction processes? Cuiyan Technology offers cutting-edge mixer settler solutions tailored to your specific needs. Experience enhanced efficiency, precise control, and superior results. Contact us today at wangzhijun@cuiyan-tec.com to explore how our advanced extraction technology can transform your operations.