Understanding Different Types of Extraction Equipment

Box Type Extraction Tanks

Box type extraction tanks are versatile workhorses in the chemical engineering industry. These robust vessels excel in handling a wide range of materials, from solid-liquid to liquid-liquid extractions. Their design allows for easy loading and unloading, making them ideal for batch processing. The rectangular shape of box type tanks ensures efficient space utilization in your facility, while their sturdy construction withstands the rigors of industrial use. Consider these tanks for applications requiring thorough mixing and extended contact time between phases.

Tubular Extraction Tanks

When it comes to continuous flow operations, tubular extraction tanks shine. Their cylindrical design promotes uniform flow patterns, enhancing mass transfer efficiency. These tanks are particularly suitable for processes requiring precise temperature control, as their shape allows for effective heat exchange. Tubular extraction tanks find extensive use in industries such as petrochemicals and food processing, where maintaining consistent product quality is paramount. If your operation demands high throughput and minimal downtime, tubular tanks might be your go-to solution.

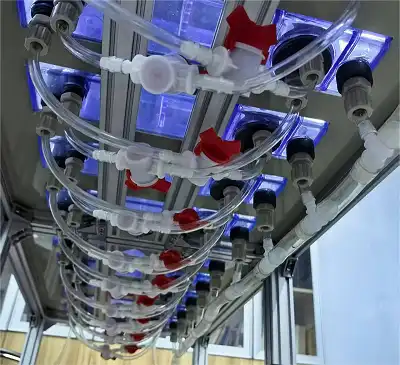

Micro Extraction Tanks

In the era of miniaturization, micro extraction tanks are making waves. These compact units are perfect for small-scale operations, pilot plants, or laboratories. Despite their size, they pack a punch in terms of extraction efficiency. Micro tanks offer advantages such as reduced solvent consumption, faster processing times, and improved control over extraction parameters. They're invaluable tools for process development and optimization before scaling up to full production. Consider micro extraction tanks when working with precious or limited samples, or when rapid prototyping is essential.

Factors to Consider When Selecting Extraction Equipment

Process Requirements and Material Compatibility

The nature of your extraction process should be the primary driver in equipment selection. Consider factors such as the physical and chemical properties of your feed materials, desired product purity, and required throughput. Material compatibility is crucial – ensure that the equipment's construction materials can withstand the corrosive or abrasive nature of your process fluids. For instance, when dealing with aggressive solvents, you might opt for tanks lined with specialized polymers or constructed from high-grade stainless steel. Always consult with equipment manufacturers to verify compatibility and discuss any potential issues.

Efficiency and Performance Metrics

Extraction efficiency is a key performance indicator that directly impacts your bottom line. Look for equipment features that enhance mass transfer, such as optimized mixing mechanisms or advanced contact designs. Consider factors like extraction yield, selectivity, and the number of theoretical stages achieved. Modern extraction equipment often comes equipped with sensors and control systems that allow real-time monitoring and adjustment of process parameters. This level of control can significantly boost efficiency and product consistency. Don't hesitate to request performance data or case studies from equipment suppliers to gauge how their solutions stack up in real-world applications.

Scalability and Future-Proofing

As your business grows, so too should your extraction capabilities. When selecting equipment, think beyond your current needs and consider future expansion plans. Modular systems offer flexibility, allowing you to add capacity incrementally. Look for equipment that can be easily integrated into automated production lines or upgraded with new features. Additionally, consider the equipment's adaptability to different extraction processes – versatility can be a significant asset as your product portfolio evolves. Engaging with suppliers who offer comprehensive support, including equipment modifications and process optimization services, can ensure your extraction setup remains cutting-edge for years to come.

Advanced Extraction Technologies and Their Applications

Centrifugal Extractors

Centrifugal extractors represent a leap forward in liquid-liquid extraction technology. These high-performance units leverage centrifugal force to dramatically accelerate the separation of immiscible liquids. The result is a compact, efficient extraction process that outperforms traditional gravity-based methods. Centrifugal extractors excel in applications requiring rapid mass transfer, such as the recovery of precious metals or the purification of pharmaceuticals. Their ability to handle emulsions and achieve high separation efficiency makes them invaluable in challenging extraction scenarios. Consider centrifugal extractors when space is at a premium or when dealing with systems prone to emulsification.

Extraction Towers

For continuous, countercurrent extraction processes, extraction towers stand tall – both literally and figuratively. These vertical columns provide excellent mass transfer efficiency through their multi-stage design. Extraction towers come in various configurations, including packed, tray, and pulsed columns, each offering unique advantages. They're particularly well-suited for applications in the petrochemical industry, such as aromatics extraction or olefin purification. The high theoretical stage count achievable in extraction towers translates to superior separation performance. When considering extraction towers, pay close attention to factors like flooding point, pressure drop, and mass transfer coefficients to ensure optimal operation.

Emerging Extraction Technologies

The field of extraction is continually evolving, with new technologies pushing the boundaries of what's possible. Supercritical fluid extraction, for instance, harnesses the unique properties of supercritical fluids to achieve highly selective extractions. This technology finds applications in diverse fields, from decaffeinating coffee to extracting valuable compounds from natural products. Another promising area is membrane-based extraction, which offers the potential for continuous, low-energy separations. As these technologies mature, they're opening up new possibilities for more efficient and environmentally friendly extraction processes. Staying informed about these emerging technologies can give you a competitive edge in your industry.

Conclusion

Choosing the right extraction equipment is a critical decision that impacts the efficiency and success of your chemical engineering operations. By understanding the various types of equipment available, considering key factors like process requirements and scalability, and staying abreast of advanced technologies, you can make informed decisions that optimize your extraction processes. Remember, the best choice often depends on your specific needs, so don't hesitate to consult with experts and conduct thorough evaluations before making your selection.

Contact Us

Ready to elevate your extraction capabilities? Cuiyan Technology offers cutting-edge extraction equipment tailored to your unique needs. From box type extraction tanks to advanced centrifugal extractors, we have the solutions to boost your efficiency and product quality. Contact us today at wangzhijun@cuiyan-tec.com to discuss how we can optimize your extraction processes and drive your business forward.