The Fundamentals of Mixer Settler Technology

Design Principles and Components

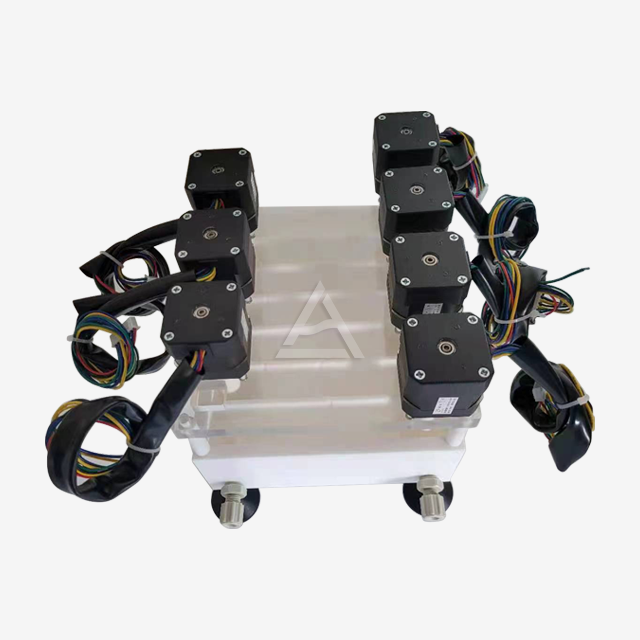

Mixer settlers are ingeniously designed to maximize extraction efficiency while maintaining a compact footprint. The core components include a mixing chamber, where vigorous agitation occurs, and a settling chamber, where gravity-driven separation takes place. Advanced models feature adjustable weirs, allowing operators to fine-tune the interface between phases for optimal separation. The choice of construction materials is crucial, with options ranging from corrosion-resistant polymers like PTFE to durable metals such as SUS316L, ensuring compatibility with a wide array of chemical environments.

Operational Mechanisms

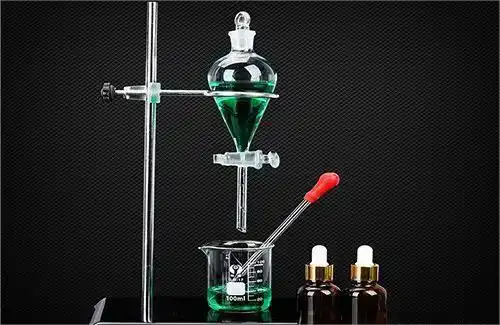

The operational beauty of mixer settlers lies in their ability to create intimate contact between immiscible phases. In the mixing stage, carefully controlled agitation disperses one phase into another, creating a large interfacial area for mass transfer. As the mixture flows into the settling chamber, reduced turbulence allows droplets to coalesce and separate based on density differences. This continuous process can be scaled up through multiple stages, enabling complex separations that would be impractical with other technologies.

Advantages Over Traditional Separation Methods

Compared to conventional separation techniques, mixer settlers offer several distinct advantages. Their modular nature allows for easy scaling and customization, adapting to changing production needs. The high extraction rates achieved through efficient mixing and precise phase control often result in superior product purity. Additionally, the closed-system design minimizes environmental exposure and reduces solvent losses, contributing to both safety and cost-effectiveness in industrial operations.

Applications Across Industries

Rare Earth Element Extraction

In the critical field of rare earth element extraction, mixer settlers play a pivotal role. The process of separating valuable elements like neodymium and dysprosium from ore concentrates requires multiple extraction stages. Mixer settlers excel in this application due to their ability to handle the precise pH and concentration controls needed for selective extraction. The modular nature of these devices allows for the creation of complex extraction circuits, each stage optimized for specific elemental separation, resulting in high-purity rare earth products essential for advanced technologies.

Nuclear Fuel Reprocessing

The nuclear industry relies heavily on mixer settler technology for the delicate task of separating uranium and plutonium in fuel reprocessing. This application demands the utmost precision and safety, which mixer settlers provide through their enclosed design and highly controlled mixing and settling processes. By utilizing specialized organic solvents and carefully tuned operational parameters, these devices achieve the exacting standards required for nuclear material handling, contributing to both energy production and non-proliferation efforts.

Wastewater Treatment and Metal Recovery

Environmental applications of mixer settlers are gaining prominence, particularly in wastewater treatment and metal recovery. These versatile units can efficiently remove heavy metals like copper and zinc from industrial effluents, contributing to water purification and resource conservation. The ability to adjust mixer settler parameters allows for the treatment of varying waste streams, making them invaluable in circular economy initiatives. Moreover, the recovery of valuable metals from wastewater not only reduces environmental impact but also creates economic opportunities in resource recycling.

Optimizing Mixer Settler Performance

Process Parameter Tuning

Achieving peak performance in mixer settler operations requires meticulous tuning of process parameters. Key variables include agitation speed, phase ratio, and residence time. Advanced systems incorporate real-time monitoring of pH, temperature, and interface levels, allowing for dynamic adjustments. This level of control ensures that extraction efficiency remains high even as feed compositions vary, a common challenge in industrial settings. Operators can leverage this flexibility to balance throughput with separation quality, optimizing overall process economics.

Material Selection and Maintenance

The longevity and reliability of mixer settlers hinge on proper material selection and maintenance practices. For corrosive environments, PTFE-lined or titanium-constructed units offer exceptional chemical resistance. Regular inspection of seals, agitator components, and weir mechanisms is crucial to prevent leaks and maintain separation efficiency. Implementing a preventive maintenance schedule, including periodic cleaning and calibration of sensors, ensures consistent performance and minimizes downtime in critical processes.

Integration with Advanced Control Systems

Modern mixer settler installations benefit greatly from integration with advanced control systems. Programmable Logic Controllers (PLCs) enable precise automation of multi-stage extraction processes, reducing operator intervention and enhancing safety. Data logging and analysis capabilities provide insights for continuous improvement, allowing engineers to identify optimization opportunities. Some cutting-edge systems even incorporate machine learning algorithms to predict maintenance needs and suggest parameter adjustments, pushing the boundaries of efficiency in liquid-liquid extraction.

Conclusion

Mixer settlers stand as a testament to engineering ingenuity in the field of phase separation. Their ability to combine efficient mixing with controlled settling has made them indispensable across a spectrum of industries, from rare earth extraction to environmental remediation. As we've explored, the benefits of mixer settlers extend beyond mere separation efficiency, encompassing flexibility, safety, and resource conservation. With ongoing advancements in materials science and control systems, the future of mixer settler technology looks bright, promising even greater precision and sustainability in chemical processing operations.

Contact Us

Elevate your phase separation processes with Cuiyan Technology's state-of-the-art mixer settler technology. Experience unparalleled efficiency, customization, and support tailored to your specific industry needs. Contact us today at wangzhijun@cuiyan-tec.com to discover how our solutions can transform your operations.