Understanding the Economics of Pilot Scale Mixer Settlers

Initial Investment and Setup Costs

The upfront costs of a pilot scale mixer settler system can vary widely depending on the configuration, materials, and customization options chosen. Typically, investments range from $10,000 to $50,000 for a basic setup. Factors influencing the price include mixing volume capacity, construction materials (e.g., PP, PPH, or PMMA), and additional features like temperature control or pH adjustment devices.

When budgeting for your pilot scale mixer settler, consider these key components:

- Mixing and settling chambers

- Agitation system

- Pumps and piping

- Control systems and sensors

- Installation and commissioning

While the initial investment may seem substantial, it's important to view it as a strategic expenditure that can lead to significant cost savings in the long run.

Operational Costs and Resource Efficiency

One of the primary advantages of pilot scale mixer settlers is their operational efficiency. These systems typically consume less energy and require fewer resources compared to full-scale industrial extractors. Key operational costs to consider include:

- Energy consumption for agitation and pumping

- Chemical reagents and solvents

- Maintenance and replacement parts

- Labor for operation and monitoring

By optimizing processes at the pilot scale, companies can significantly reduce wastage of valuable chemicals and minimize energy consumption when scaling up. This not only cuts costs but also aligns with sustainable manufacturing practices.

Return on Investment (ROI) Calculation

To assess the financial viability of implementing a pilot scale mixer settler, it's crucial to calculate the expected return on investment. Consider the following factors:

- Projected increase in product yield or quality

- Reduction in full-scale process development time

- Savings from avoiding costly mistakes in large-scale implementation

- Potential for new product development or market expansion

A well-executed pilot study can lead to ROI within months, especially for high-value products or when optimizing existing processes. For instance, in rare earth extraction, even a small improvement in efficiency can translate to substantial financial gains when scaled up.

Enhancing Extraction Efficiency with Pilot Scale Technology

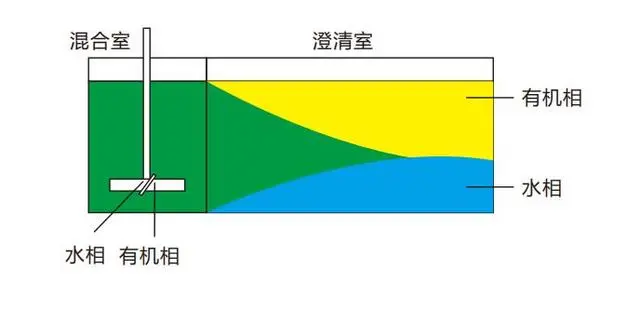

Optimizing Mixing and Settling Parameters

Pilot scale mixer settlers offer unparalleled flexibility in fine-tuning extraction processes. By adjusting parameters such as agitation speed, phase ratios, and residence times, operators can achieve optimal mass transfer and phase separation. This level of control allows for:

- Improved extraction rates of target compounds

- Reduced emulsion formation and faster phase disengagement

- Minimized carryover of unwanted substances

Through systematic experimentation, companies can determine the ideal operating conditions that maximize efficiency while minimizing resource consumption.

Scaling Considerations and Process Validation

One of the key advantages of pilot scale mixer settlers is their ability to bridge the gap between laboratory experiments and full-scale production. When scaling up, consider these factors:

- Geometric similarity of mixing and settling chambers

- Maintaining optimal flow patterns and residence times

- Adjusting for changes in surface area to volume ratios

By validating processes at the pilot scale, companies can confidently predict performance at industrial scales, reducing the risk of costly failures during scale-up.

Advanced Monitoring and Control Systems

Modern pilot scale mixer settlers often incorporate sophisticated monitoring and control systems. These can include:

- Real-time pH and temperature sensors

- Inline spectroscopic analysis for composition monitoring

- Automated interface level control

- Data logging and process trend analysis

By leveraging these advanced features, operators can gain deeper insights into the extraction process, enabling rapid optimization and troubleshooting. This data-driven approach not only improves efficiency but also enhances process reliability and reproducibility.

Case Studies: Successful Implementation of Pilot Scale Mixer Settlers

Rare Earth Element Extraction Optimization

A leading rare earth processing company implemented a pilot scale mixer settler to optimize their solvent extraction process. By fine-tuning the organic-to-aqueous phase ratio and adjusting settler residence times, they achieved:

- 15% increase in rare earth recovery

- 20% reduction in organic solvent consumption

- Improved selectivity for high-value heavy rare earth elements

These improvements, when scaled to their industrial operations, resulted in annual savings of over $2 million and a significant boost in product quality.

Pharmaceutical API Purification Enhancement

A pharmaceutical manufacturer utilized a pilot scale mixer settler to develop a more efficient purification process for a high-value active pharmaceutical ingredient (API). Through systematic experimentation, they:

- Reduced the number of extraction stages from 6 to 4

- Increased API yield by 8%

- Decreased solvent waste by 30%

These optimizations not only improved process economics but also aligned with green chemistry principles, enhancing the company's sustainability profile.

Battery Recycling Process Development

An innovative battery recycling startup leveraged pilot scale mixer settler technology to develop a novel process for recovering lithium and cobalt from spent lithium-ion batteries. Their pilot studies enabled:

- Rapid iteration of extraction conditions for multiple metal recovery

- Optimization of reagent concentrations to minimize environmental impact

- Demonstration of process viability for investor funding

The success of their pilot-scale work led to securing $10 million in funding for a full-scale recycling facility, positioning the company as a leader in sustainable battery technology.

Conclusion

Pilot scale mixer settlers offer a powerful tool for optimizing extraction processes across various industries. By providing a cost-effective platform for experimentation and validation, these systems enable companies to improve efficiency, reduce operational costs, and accelerate innovation. The case studies presented demonstrate the tangible benefits of implementing pilot scale technology, from rare earth extraction to pharmaceutical purification and battery recycling. As industries continue to seek more sustainable and efficient processes, the role of pilot scale mixer settlers in driving technological advancements and economic success becomes increasingly crucial.

Contact Us

Ready to optimize your extraction processes? Cuiyan Technology offers cutting-edge pilot scale mixer settler solutions tailored to your specific needs. Our expert team can guide you through process development, ensuring maximum efficiency and cost-effectiveness. Contact us today at wangzhijun@cuiyan-tec.com to explore how our technology can transform your operations.