In the realm of chemical engineering, equipment that optimizes separation processes is invaluable. Among these, the mixer settler stands out as an indispensable tool, especially in liquid-liquid extraction tasks. A mixer settler efficiently combines two immiscible liquids, enabling high-purity separation crucial for many industries. Its enduring presence across sectors emphasizes its importance in enhancing process effectiveness while maintaining compliance with strict industrial standards.

Understanding Mixer Settlers

What Are Mixer Settlers?

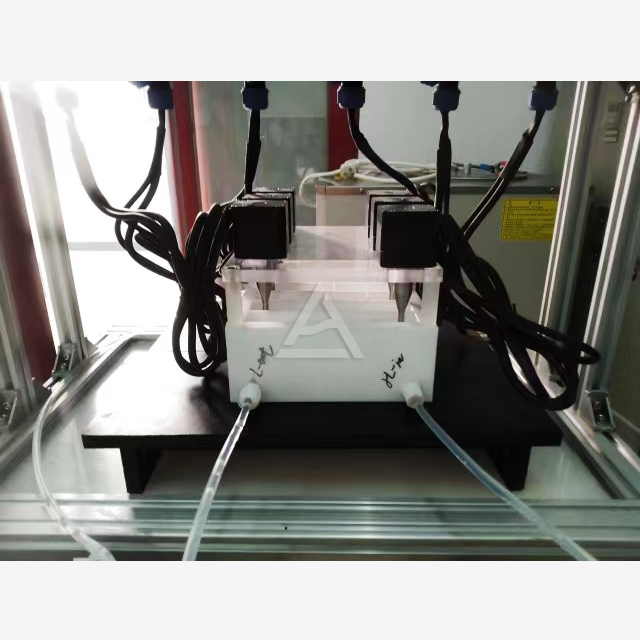

A mixer settler is specialized chemical engineering equipment designed for liquid-liquid extraction. It works by blending two immiscible liquids, like an organic solvent and an aqueous solution, to facilitate the transfer of target compounds from one phase to the other. After mixing, the liquids flow into a settling section where gravity separation occurs, allowing the phases to separate cleanly. This equipment evolved from simple extraction methods to sophisticated systems providing higher extraction efficiency, scalability, and customization. Historically, mixer settlers revolutionized industrial extraction operations in fields like metallurgy and pharmaceuticals, becoming fundamental in processes requiring precise separation with minimal contamination.

How Mixer Settlers Work?

The operation of a mixer settler involves two key components: the mixer and the settler. The mixer agitates the feed streams, ensuring intimate contact between the phases and enhancing mass transfer. Once mixed, the fluid enters the settler section, where downward flow slows, enabling gravity to separate the denser phase from the lighter one. Adjustable parameters such as agitator speed, residence time, and interface height optimize separation efficiency. A typical flowchart of the process illustrates continuous liquid introduction, mixing, settling, and extraction, offering a seamless and controllable workflow ideal for sensitive chemical operations.

Mixer Settler Design and Applications

Mixer Settler Design Principles

Designing a mixer settler demands careful consideration of several factors to achieve optimal performance. These include the flow rate of the process fluids, material compatibility to resist corrosion or fouling, and energy consumption for mixing. Compared to alternative separation techniques like centrifugation or distillation, mixer settlers provide a more gentle method critical to preserving delicate compounds. The configuration often includes modular stages, enabling scalability and flexible throughput adjustment. Materials such as polypropylene (PP), stainless steel (SUS316L), and PTFE offer robust corrosion resistance, extending the operational lifespan. Energy efficiency is enhanced by advanced mixing mechanisms that lower the required agitation power without sacrificing extraction rate, underscoring the design’s balance between effectiveness and sustainability.

Applications in Chemical Engineering

Mixer settlers are highly versatile and find applications in diverse chemical engineering fields. Pharmaceuticals and nutraceuticals rely on them for extracting precise botanical compounds with GMP compliance. In food and beverage production, mixer settlers ensure food-grade safety while preserving fragile aroma and flavor molecules in essential oils and natural colors. Cosmetics manufacturers utilize gentle extraction modes to maintain the bioactivity of ingredients for skincare and perfumes. Industrial sectors employ heavy-duty mixer settlers for processes like rare earth element extraction, lithium battery recycling, and wastewater treatment. These real-world applications demonstrate their adaptability and reliability across complex operations demanding both purity and throughput.

Advantages of Mixer Settlers

Efficiency and Performance

The efficiency of mixer settlers surpasses many conventional separation technologies due to the precise control of mixing and settling stages. They deliver high extraction rates through adjustable agitator speeds and controlled residence times, minimizing losses and enhancing yield. Studies indicate energy savings up to 20% with modular designs compared to legacy equipment, reducing operational costs significantly. Patented features like anti-bubbling baffles ensure stable phase interfaces, preventing emulsions and facilitating clearer separation. This reliable performance is particularly critical in pharmaceutical and nuclear industries, where cross-contamination and low purity can have severe consequences.

Cost-Effectiveness

Investment in advanced mixer settlers brings measurable long-term economic benefits. The robust construction using corrosion-resistant materials decreases maintenance frequency and downtime. Modular assembly and plug-in sensors reduce installation time and facilitate easier upgrades. By cutting energy consumption through optimized mixing mechanisms, operational expenses decrease noticeably. The adaptable stage number allows tailoring equipment capacity to evolving production demands, which maximizes asset utilization without unnecessary spending. Additionally, a zero-leak design achieved via seamless welding and PTFE seals reduces contamination risks and saves costs related to losses or cleanup. Overall, this technological sophistication translates into a strong ROI for process engineers and plant managers.

Selecting the Right Mixer Settler

Features to Consider

Choosing an appropriate mixer settler involves evaluating features aligned with specific operational needs. Capacity should match process volumes, ranging from laboratory-scale 200ml to industrial 3L and beyond, with options for customization. Compatibility of wetted materials is essential - PP, PVC, and titanium are selected depending on the chemical environment's aggressiveness. Functionality enhancements include temperature control devices, pH adjustment, water-bath jackets, and overflow prevention tanks, enabling precise process regulation. When compared with centrifuges or distillation columns, mixer settlers excel in processing sensitive materials without inducing thermal degradation or excessive shear stress. A comprehensive feature comparison emphasizes ease of operation, maintenance, and scalability potential.

Supplier and Cost Analysis

Supplier reliability greatly influences the successful deployment of mixer settlers. Key factors include proven experience, adherence to international standards like ASME and ISO, and after-sales support availability. Shaanxi Cuiyan Technology Co., Ltd, a recognized industry leader since 2012, exemplifies these qualities by delivering patented, high-performance mixer settlers tailored to complex applications such as rare earth extraction and battery recycling. Pricing transparently reflects customization and quality assurances, with options for modular expansion enabling cost management. Engaging with reputed suppliers ensures access to engineering expertise, installation guidance, and troubleshooting support, building operational confidence and minimizing total cost of ownership.

Company Introduction and Product Services

Our company specializes in providing high-quality mixer settlers tailored to meet the specific needs of chemical engineering industries. With a focus on innovation and customer satisfaction, we offer a range of services including installation, maintenance, and custom solutions to ensure optimal performance and efficiency.

Conclusion

The mixer settler remains a cornerstone in chemical engineering separation processes, delivering precision, efficiency, and reliability across various industries. Its design versatility - from material composition to customizable features - allows it to meet stringent requirements in pharmaceutical purification, battery material recovery, and wastewater treatment. When paired with a trusted manufacturer like Shaanxi Cuiyan Technology Co., Ltd, operators gain solutions backed by innovation, compliance, and comprehensive support. Investing in scientifically engineered mixer settlers is a decisive step toward boosting process quality while controlling costs.

FAQs

What is the difference between a mixer settler and a centrifuge?

While both equipment types separate immiscible liquids, mixer settlers separate based on gravity settling after gentle mixing, preserving sensitive compounds. Centrifuges use high rotational forces to accelerate separation but may induce shear stress. Mixer settlers offer continuous, controlled extraction suitable for delicate processes, whereas centrifuges are more suited for rapid, high-throughput separations where physical robustness is essential.

How do I maintain a mixer settler?

Routine maintenance includes cleaning with deionized water to remove residues, inspecting seals for wear, and annual replacement of gaskets to prevent leaks. Calibrating agitator speeds and checking sensors for pH and temperature accuracy optimize performance. Preventive upkeep emphasizes avoiding contamination and mechanical failure, ensuring consistent process outcomes and extending equipment lifespan.

Can mixer settlers be customized for specific applications?

Yes, mixer settlers offer extensive customization. Options range from adjustable stage quantities, variable agitator speed control, to incorporation of temperature or pH control devices. Material selection can be tailored to resist corrosive media, and design variations accommodate space constraints. This adaptability allows clients to optimize the equipment for diverse industrial processes, from nuclear fuel reprocessing to rare earth recovery.

Where to Buy Mixer Settler?

Considering a mixer settler for your industrial needs? Shaanxi Cuiyan Technology Co., Ltd offers a broad portfolio of configurable mixer settlers designed to meet rigorous chemical processing challenges. With decades of industry experience and a dedication to quality, they provide machines combining innovation with operational excellence. Reach out to discuss your application requirements or request a quote by contacting us at wangzhijun@cuiyan-tec.com. Let us partner with you to optimize your separation solutions.

References

Geankoplis, C. J. "Transport Processes and Separation Process Principles." Prentice Hall, 2003.

King, C. J. "Separation Processes." McGraw-Hill, 2008.

Perry, R. H., Green, D. W., & Maloney, J. O. "Perry's Chemical Engineers' Handbook." McGraw-Hill, 1997.

Dutta, B. K. "Principles of Mass Transfer and Separation Processes." PHI Learning, 2010.

Seader, J. D., Henley, E. J., & Roper, D. K. "Separation Process Principles." Wiley, 2011.

Konduru, R., Stevens, G. & Marchetti, S. "Advanced Extraction Techniques in Chemical Engineering." Elsevier, 2019.