Industrial extraction processes often hinge on precise phase separation to obtain high-purity products. A mixer settler, a robust liquid-liquid extraction device, plays a pivotal role in this context by combining agitation and settling stages within a compact apparatus. It efficiently facilitates the separation of immiscible liquid phases, making it indispensable across multiple industries including pharmaceuticals, food and beverage, cosmetics, and chemical manufacturing. Through effective mass transfer and phase separation, mixer settlers enhance operational precision and scalability - key factors for any industrial application demanding compliance and high throughput.

Introduction to Mixer Settlers

Mixer settlers are solidly established in industrial extraction thanks to their simplicity and reliability. Structurally, the unit consists of two primary zones: a mixing compartment where the solvent and feed streams thoroughly interact, and a settling compartment where gravity enables phase separation. This design promotes effective contact between two immiscible liquids - usually an organic phase and an aqueous phase - allowing solutes to transfer selectively between them. The settling section provides residence time so that phases stratify cleanly without emulsification.

Their modularity and ease of customization suit a variety of extraction targets, from botanical compounds to metals and specialty chemicals. In chemical engineering applications, such units elegantly balance agitation intensity, residence time, and phase interface control to optimize yield and purity.

Comparing Mixer Settlers with Other Separation Technologies

Navigating the range of liquid-liquid extraction equipment requires clarity on where mixer settlers excel versus alternatives like extraction columns or centrifugal extractors. Mixer settlers offer direct and controllable mixing followed by gentle gravity settling, which reduces shear forces that could degrade sensitive compounds - a critical factor in pharmaceuticals and cosmetics.

Extraction columns provide continuous counter-current contact but typically require more footprint and may pose challenges in handling viscous or particulate-laden feeds. Centrifugal extractors offer rapid separation with smaller volume but come with mechanical complexity and greater energy consumption.

Choice of equipment depends heavily on process goals, throughput, and product stability. For example, in food-grade essential oil extraction, the gentle handling of mixer settlers helps preserve aroma integrity better than high-shear alternatives.

Consider these points illustrating mixer settler advantages:

- Efficiency and Control: Operators can adjust agitator speed, phase interface height, and the number of stages in mixer settlers, providing unparalleled precision in extraction dynamics.

- Cost-Effectiveness: The modular design simplifies maintenance and scaling, reducing downtime and capital expenditure compared to complex distillation or membrane systems.

- Versatility: Capable of handling corrosive media and hazardous solvents when constructed from materials like SUS316L and PTFE, mixer settlers adapt to diverse chemical environments.

These factors make mixer settlers a preferred option, balancing operational flexibility and product quality, especially when scaling from pilot production to full industrial volumes.

Design and Efficiency of Mixer Settlers

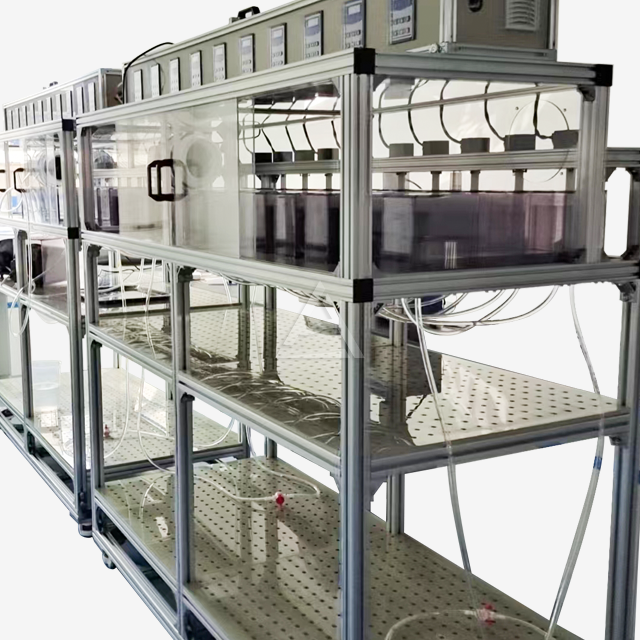

Customized design significantly influences mixer settler performance. Key elements include plate thickness, material selection, and optional accessories tailored to operational needs. Shaanxi Cuiyan Technology Co., Ltd., for example, offers mixer settler configurations from desktop base editions to environmentally friendly high editions, suiting varied industry demands.

Mixer volume options - from 200 ml laboratory units up to 3 liters or customized sizes - provide flexibility for laboratory testing and process scaling. Plate thickness can be chosen from 5mm to 10mm, determining structural durability and flow management. Material variety extends from polypropylene and PVC to premium choices like PTFE, PEEK, stainless steel (SUS), and titanium, enabling resistance against aggressive solvents and extreme pH ranges (1-14).

Production processes such as welding, bonding, bending, injection molding, and integral forming ensure equipment integrity and zero leakage risk - a critical consideration for GMP-compliant pharmaceutical and nutraceutical applications. Optional functions enhance process control:

- Temperature control devices maintain optimal extraction kinetics.

- pH adjustment devices allow precise chemistry tuning for selective solute separation.

- Water-bath jackets provide consistent thermal environments.

- Anti-overflow tanks prevent system upsets during sudden flow fluctuations.

- Watch window devices enable visual monitoring of phase behaviors in real-time.

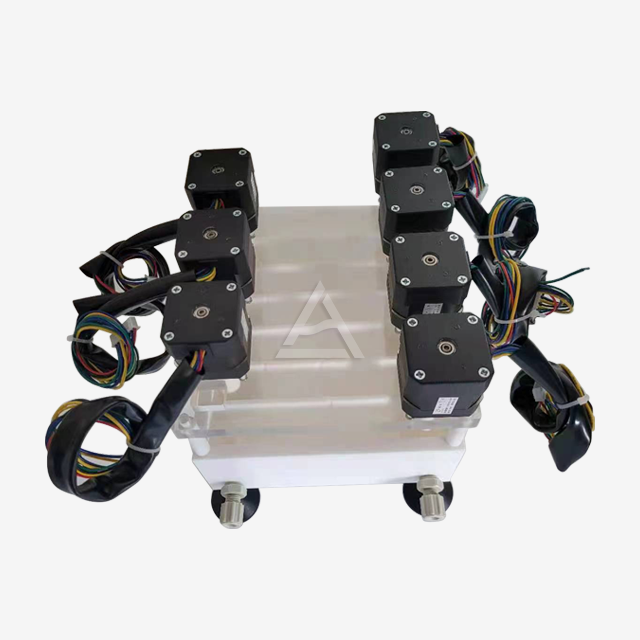

These sophisticated features contribute to remarkably high extraction rates and flawless phase separation, making operations smooth and reproducible. Adjustability of mixer settler stages, agitator speeds (100–800 RPM), and interface heights empower users to dial in exact process parameters, critical for complex separations such as rare earth element purification or lithium battery recycling.

Operating principles:

- The agitator blends feed and solvent phases to maximize mass transfer efficiency.

- Gravity separation occurs in settling compartments, augmented by patented baffle designs to prevent bubbling and phase mixing.

- Continuous multi-stage configurations enable sequential extractions within a compact footprint, reducing processing times.

Such design sophistication ensures energy efficiency, with modular setups cutting power consumption by up to 20% compared to legacy devices.

Purchasing and Cost Considerations

Selecting the right mixer settler involves balancing budget, technical requirements, and supplier reliability. Shaanxi Cuiyan Technology Co., Ltd stands out by offering tailored equipment aligned with international standards including ASME, ISO, and REACH - crucial for cross-border industrial projects.

When evaluating mixers settlers from suppliers, consider:

- The extent of customization - offering configurational flexibility affects equipment longevity and process optimization.

- Transparency and real-time monitoring capabilities (e.g., transparent PMMA materials) improve operational oversight and troubleshooting.

- After-sales support, warranty, and accessory availability impact overall lifecycle costs.

While initial prices vary by scale and options, investing in higher-quality, zero-leak designs with corrosion-resistant materials ultimately yields cost savings by reducing downtime and contamination risks.

Shaanxi Cuiyan’s experience across diverse applications - from rare earths to biological wastewater - confirms the value of investing in proven mixer settler technology backed by extensive patents and expert teams.

Shaanxi Cuiyan Technology Co., Ltd: Trusted Mixer Settler Solutions

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has been a pioneer in developing and manufacturing mixer settlers recognized for innovation, reliability, and scalability. Our comprehensive capabilities extend beyond equipment fabrication to include full extraction process development and hydrometallurgical line design. We specialize in handling complex industrial challenges like electroplating sludge treatment, precious metal waste recovery, and sustainable battery recycling.

Our products include desktop base editions, mobile standard units, and environmentally friendly high editions with volumes from small laboratory models (200 ml) to larger industrial units (3 L or customized). Constructed using advanced materials such as SUS316L, PTFE, and PMMA, our mixer settlers promise robust corrosion resistance and seamless operation. Process automation options and PLC sensor integrations enable precise monitoring of pH, temperature, and fluid levels in real-time.

Client testimonials underscore our commitment to delivering tailored solutions that optimize extraction yields while ensuring environmental compliance and user safety. Collaborating with Shaanxi Cuiyan means partnering with a team devoted to advancing your separation technologies with cutting-edge equipment backed by 100+ patents and a dedicated R&D team.

Conclusion

Mixer settlers embody a sophisticated yet accessible technology, crucial for liquid-liquid extraction across pharmaceuticals, food, cosmetics, and chemical industries. Their modular design, coupled with customizable features such as adjustable agitator speeds and corrosion-resistant materials, supports scalable, GMP-compliant, and food-grade operations. Shaanxi Cuiyan Technology Co., Ltd offers expertly engineered mixer settlers that marry precision with durability, making them an ideal choice for those seeking efficient, contamination-free extraction solutions. Integrating these units can significantly elevate your production quality while maintaining cost-effectiveness and environmental responsibility.

FAQs

What components make up a mixer settler?

A mixer settler primarily includes a mixing chamber equipped with an agitator to blend immiscible liquids and a settling compartment where the phases separate under gravity. Additional components may encompass adjustable weirs, temperature and pH control devices, overflow prevention tanks, and monitoring windows to optimize process control.

How does a mixer settler compare with distillation in extraction efficiency?

Mixer settlers perform liquid-liquid extraction efficiently by selective solute transfer without phase vaporization, preserving heat-sensitive compounds. Distillation involves phase change and can consume more energy while risking compound degradation. Therefore, mixer settlers are preferred for delicate botanical or pharmaceutical extractions requiring high purity and gentle handling.

What factors affect the efficiency of mixer settlers?

Efficiency depends on agitator speed, residence time, phase interface height, plate design, and materials resistant to corrosion. Proper adjustment of these parameters, along with maintaining zero leakage and stable phase separation, ensures optimal mass transfer and extraction yields.

Where to Buy Mixer Settler?

Shaanxi Cuiyan Technology Co., Ltd provides an extensive range of mixer settlers, including desktop base editions, mobile standard models, and environmentally friendly high editions tailored for various industrial applications. Our customizable options ensure that you find equipment perfectly suited to your operational scale and process requirements. To explore in-depth product details or request a personalized quote, contact us at wangzhijun@cuiyan-tec.com. Our experts are ready to guide you through selecting the ideal mixer settler solution that enhances the precision and efficiency of your extraction processes.

References

Kumar, P., & Singh, V. (2018). Liquid-Liquid Extraction: Fundamentals and Applications in Hydrometallurgy. Chemical Engineering Journal.

Lee, J. H., et al. (2020). Advances in Mixer Settler Design for Enhanced Phase Separation in Chemical Manufacturing. Separation and Purification Technology.

Smith, R. W. (2019). Industrial Extraction and Separation Processes: A Comprehensive Review. Journal of Chemical Technology and Biotechnology.

Zhang, Y., & Chen, L. (2021). Application of Mixer Settlers in Rare Earth Element Purification. Minerals Engineering.

Brown, A. & Wilson, T. (2017). Sustainable Battery Recycling: Chemical Extraction Technologies and Equipment. Journal of Cleaner Production.

Johnson, M. E., & Adams, S. J. (2019). Enhancing Wastewater Treatment through Efficient Heavy Metal Extraction Systems. Environmental Science & Technology Reports.