Factors Influencing Material Selection for Copper Solvent Extraction Equipment

Chemical Compatibility and Corrosion Resistance

In copper solvent extraction, the equipment faces constant exposure to harsh chemicals and corrosive substances. The chosen material must withstand these conditions without degradation. Stainless steel alloys, particularly SUS316L, exhibit remarkable resistance to a wide range of acids and bases commonly used in copper extraction processes. This grade of stainless steel contains molybdenum, which enhances its corrosion resistance, especially against chlorides and sulfuric acid - prevalent in copper leaching solutions.

PTFE, on the other hand, boasts near-universal chemical resistance. Its inert nature makes it impervious to almost all chemicals used in copper extraction, including strong acids, bases, and organic solvents. This exceptional chemical compatibility ensures that PTFE components maintain their integrity over extended periods, reducing the risk of contamination and equipment failure.

Mechanical Properties and Durability

The mechanical strength of the mixer settler material plays a crucial role in its performance and longevity. Stainless steel excels in this aspect, offering high tensile strength and excellent wear resistance. This robustness allows for the construction of larger-scale extraction units capable of handling higher pressures and flow rates. The durability of stainless steel also translates to lower maintenance requirements and extended equipment lifespan.

While PTFE may not match the mechanical strength of stainless steel, it compensates with its unique properties. PTFE's low coefficient of friction reduces wear on moving parts, enhancing the overall efficiency of the extraction process. Additionally, its non-stick surface prevents the buildup of deposits, simplifying cleaning procedures and minimizing downtime.

Thermal Stability and Operating Temperature Range

Copper solvent extraction often involves elevated temperatures, making the thermal stability of materials a critical consideration. Stainless steel maintains its structural integrity across a wide temperature range, from cryogenic conditions to several hundred degrees Celsius. This versatility allows for flexibility in process design and operation.

PTFE, while not suitable for extremely high temperatures, remains stable up to about 260°C (500°F). This temperature range adequately covers most copper extraction processes. PTFE's low thermal conductivity can also be advantageous in maintaining temperature stability within the extraction system, potentially leading to energy savings in temperature-controlled operations.

Comparative Analysis of Materials for Copper Solvent Extraction

Stainless Steel (SUS316L) Performance in Copper Extraction

SUS316L stainless steel has proven its worth in numerous copper solvent extraction installations worldwide. Its austenitic structure provides excellent toughness and ductility, crucial for withstanding the dynamic forces present in mixer settler units. The high chromium content (16-18%) forms a protective oxide layer, continuously regenerating upon damage and offering sustained corrosion resistance.

In practical applications, SUS316L mixer settlers have demonstrated impressive longevity, often serving for decades with proper maintenance. The material's ability to resist pitting and crevice corrosion, common challenges in copper extraction environments, contributes significantly to this extended service life. Moreover, the smooth surface finish achievable with stainless steel promotes efficient phase separation, a critical factor in extraction performance.

PTFE's Unique Advantages in Solvent Extraction Processes

PTFE brings a set of distinctive benefits to copper solvent extraction equipment. Its hydrophobic nature prevents aqueous solutions from adhering to surfaces, facilitating cleaner phase separation and reducing carryover between stages. This property is particularly valuable in achieving high copper recovery rates and maintaining extract purity.

The material's exceptional chemical inertness extends beyond corrosion resistance. PTFE does not catalyze unwanted side reactions or leach contaminants into the process streams, ensuring the integrity of the extracted copper. In scenarios where ultra-high purity is required, such as in electronic-grade copper production, PTFE components can be instrumental in meeting stringent quality standards.

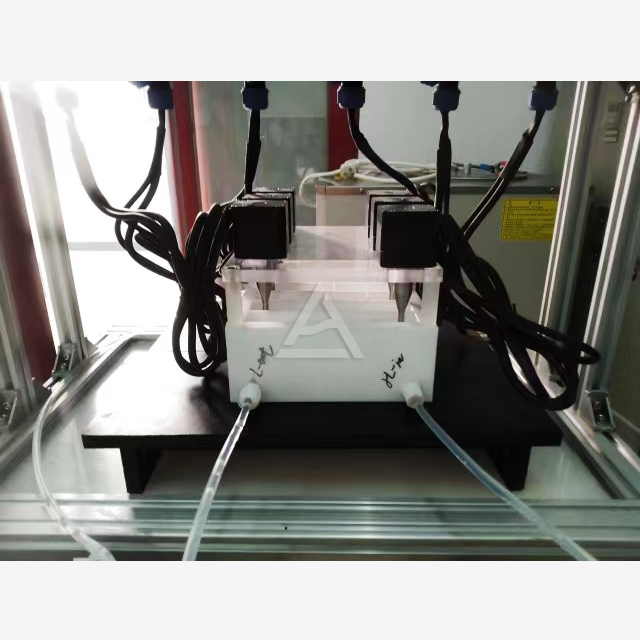

Hybrid Material Solutions for Optimized Performance

Innovative approaches in mixer settler design often incorporate hybrid material solutions, leveraging the strengths of both stainless steel and PTFE. For instance, a stainless steel frame might provide structural support and mechanical strength, while PTFE-lined internals offer superior chemical resistance in critical areas. This combination allows for larger, more robust extraction units that maintain excellent chemical compatibility.

Advanced manufacturing techniques, such as PTFE spray coating or sheet lining on stainless steel surfaces, have enabled the development of hybrid mixer settlers that outperform single-material designs. These hybrid solutions often result in equipment that combines the best attributes of both materials - the structural integrity and heat transfer capabilities of stainless steel with the chemical resistance and non-stick properties of PTFE.

Practical Considerations for Material Selection in Copper Extraction Equipment

Cost-Benefit Analysis of Different Materials

When evaluating materials for copper solvent extraction equipment, initial costs must be weighed against long-term benefits. Stainless steel, while potentially more expensive upfront, offers excellent durability and a proven track record in industrial applications. Its longevity often translates to lower total cost of ownership over the equipment's lifecycle. Additionally, the recyclability of stainless steel aligns with sustainability goals, an increasingly important factor in modern industrial processes.

PTFE components, though typically more expensive per unit than stainless steel, can offer significant savings in specific scenarios. Their superior chemical resistance may reduce the frequency of replacements and downtime, particularly in highly corrosive environments. The non-stick properties of PTFE can also lead to operational savings by reducing cleaning requirements and minimizing product loss due to adhesion.

Maintenance and Lifecycle Considerations

The maintenance requirements and expected lifecycle of mixer settler materials significantly impact their suitability for copper extraction processes. Stainless steel equipment generally requires minimal maintenance, often limited to routine inspections and occasional cleaning. Its resistance to wear and corrosion contributes to extended service life, reducing the frequency of major repairs or replacements.

PTFE components, while highly resistant to chemical attack, may require more careful handling during maintenance due to their softer nature. However, their non-stick properties can simplify cleaning procedures, potentially reducing maintenance time and chemical usage. The lifecycle of PTFE equipment in copper extraction can be remarkably long, provided it's not subjected to mechanical stresses beyond its design limits.

Regulatory Compliance and Industry Standards

Material selection for copper solvent extraction must also consider relevant regulatory requirements and industry standards. Both stainless steel and PTFE are widely accepted materials in the chemical processing industry, complying with various international standards. Stainless steel, particularly SUS316L, meets ASME, ISO, and REACH standards, facilitating its use in global projects.

PTFE's inertness and non-toxicity make it compliant with stringent food and pharmaceutical grade standards, which can be relevant in high-purity copper extraction for specialized applications. When selecting materials, it's crucial to consider not only current regulations but also anticipated future standards, ensuring the longevity and compliance of the extraction equipment.

Conclusion

The choice of material for copper solvent extraction equipment is a critical decision that impacts operational efficiency, product quality, and long-term costs. While both stainless steel (SUS316L) and PTFE offer distinct advantages, the optimal selection often depends on specific process requirements, environmental conditions, and operational goals. In many cases, a hybrid approach combining the strengths of both materials yields the best results. As copper extraction technologies continue to evolve, ongoing research into advanced materials and innovative designs will further enhance the efficiency and sustainability of these critical industrial processes.

Contact Us

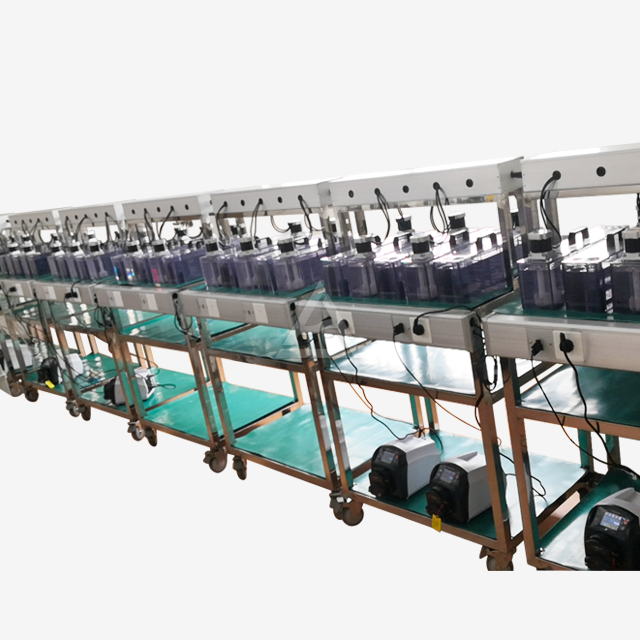

Ready to optimize your copper solvent extraction process? Cuiyan Technology offers cutting-edge mixer settler solutions tailored to your specific needs. Our expert team can guide you through material selection, ensuring maximum efficiency and longevity for your extraction equipment. Experience the benefits of advanced technology and superior performance. Contact us today at wangzhijun@cuiyan-tec.com to discuss how we can elevate your copper extraction operations.