Understanding Mixer Settlers: Design and Functionality

The Anatomy of a Mixer Settler

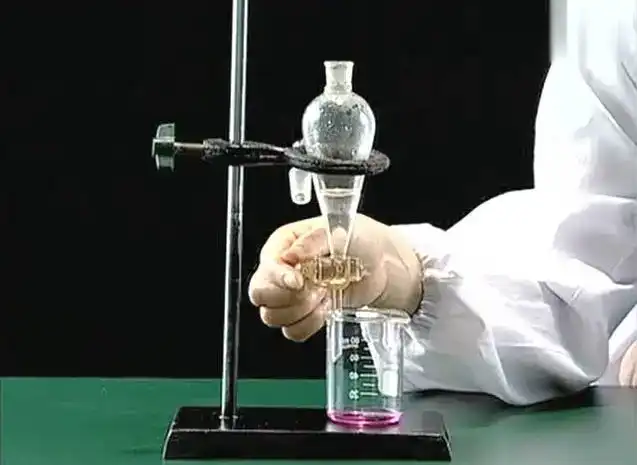

Mixer settlers are ingeniously designed extraction devices consisting of two primary components: the mixing chamber and the settling chamber. In the mixing chamber, immiscible liquids are vigorously agitated to promote mass transfer between phases. This is typically achieved through the use of impellers or baffles that create turbulent flow patterns. The settling chamber, on the other hand, provides a quiescent environment where gravity separation occurs, allowing the two phases to separate based on their density differences.

The design of mixer settlers can vary depending on the specific application and manufacturer. Some key features include:

- Adjustable weirs for precise control of phase interface height

- Baffles to prevent entrainment and improve phase separation

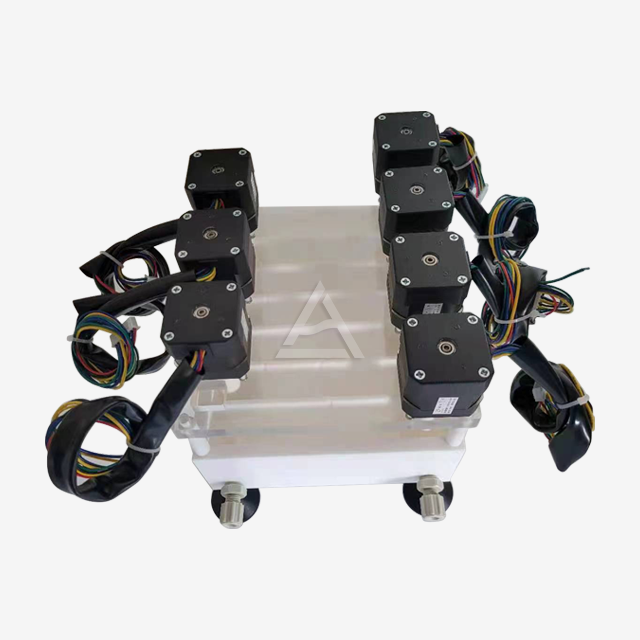

- Variable speed agitators for optimized mixing intensity

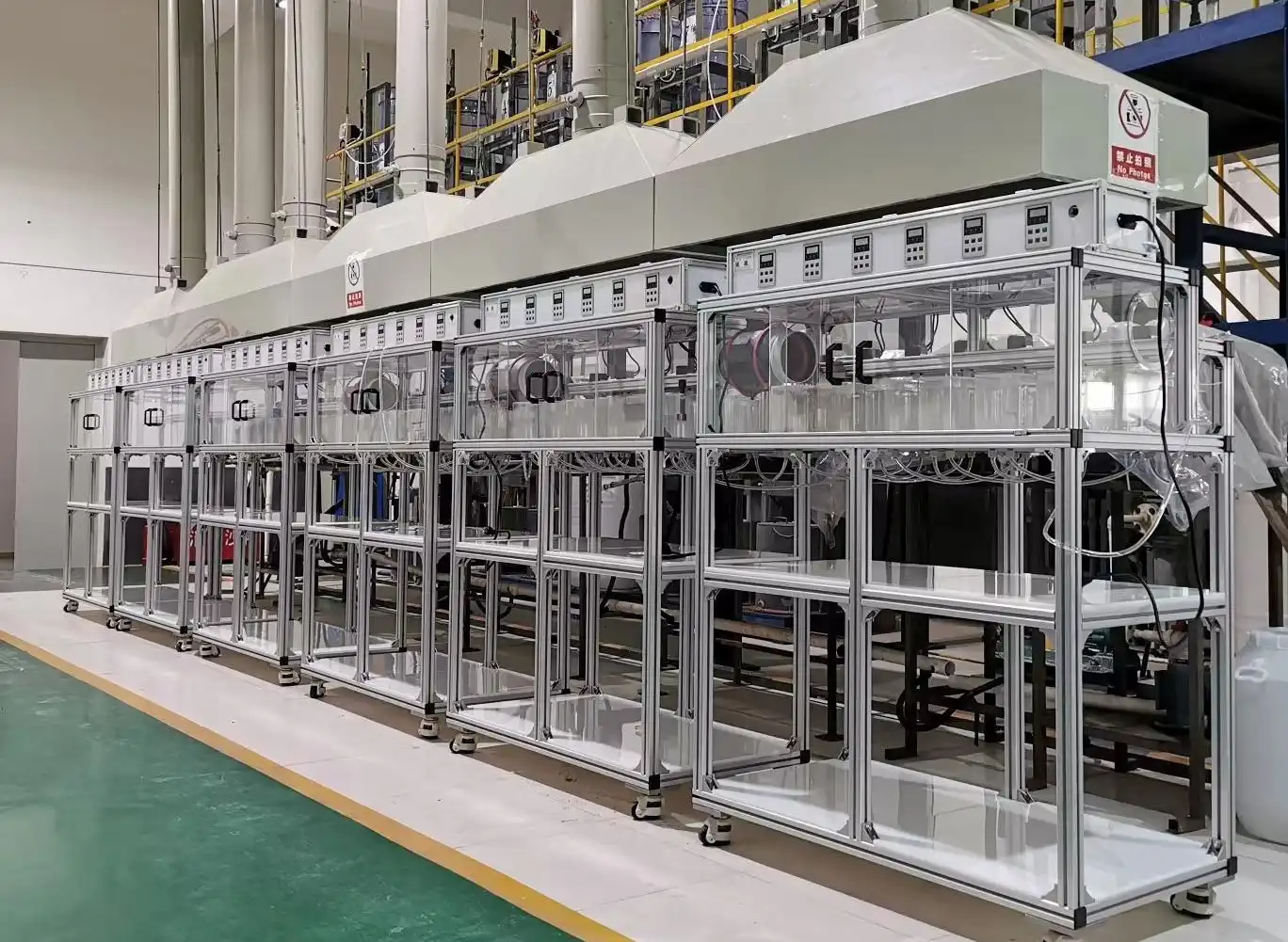

- Modular construction allowing for easy scaling and maintenance

Operating Principles and Mass Transfer

The operation of a mixer settler relies on the principle of liquid-liquid extraction. When two immiscible liquids are brought into contact, solutes can transfer from one phase to another based on their relative solubilities. In the mixing stage, the large interfacial area created by agitation enhances this mass transfer process. The efficiency of extraction is influenced by factors such as contact time, interfacial area, and the distribution coefficient of the solute between phases.

During the settling stage, the mixed phases separate under the influence of gravity. The heavier phase settles to the bottom, while the lighter phase rises to the top. The clear interface between these phases allows for easy withdrawal of the purified streams. By connecting multiple mixer settler units in series, multi-stage extraction processes can be achieved, significantly improving overall separation efficiency.

Customization and Adaptability

One of the hallmarks of mixer settlers is their adaptability to various process requirements. Manufacturers like Cuiyan Technology offer a range of customization options, including:

- Material selection (e.g., PP, PTFE, SUS316L) for compatibility with different chemical environments

- Mixing volumes from 200ml to 3L or custom sizes

- Optional features such as temperature control devices and pH adjustment systems

- Transparent construction materials (e.g., PMMA) for process visualization

This flexibility allows engineers to tailor mixer settler configurations to specific separation challenges, optimizing performance for each unique application.

Comparative Analysis: Mixer Settlers vs. Alternative Extraction Technologies

Mixer Settlers and Centrifugal Extractors

Centrifugal extractors represent another class of liquid-liquid extraction equipment, utilizing centrifugal force to enhance phase separation. While both technologies have their merits, they differ significantly in operation and application:

Mixer Settlers:

- Lower capital cost and energy consumption

- Simpler design with fewer moving parts, leading to easier maintenance

- Better suited for processes with longer residence time requirements

- Excellent for handling systems with high interfacial tension

Centrifugal Extractors:

- Faster separation times, ideal for time-sensitive processes

- Smaller footprint, beneficial in space-constrained environments

- Better performance with emulsion-prone systems

- Higher throughput capacity per unit volume

Packed Columns and Mixer Settlers: A Side-by-Side Comparison

Packed columns are vertical extraction units filled with packing material to increase interfacial area. Comparing these with mixer settlers reveals distinct operational characteristics:

Mixer Settlers:

- Discrete stages allow for easier process control and optimization

- More flexible in handling varying flow rates and ratios

- Lower pressure drop across the system

- Easier scale-up from laboratory to industrial scale

Packed Columns:

- Continuous operation with potential for higher efficiency in some applications

- Better suited for systems with low density differences between phases

- Can achieve higher theoretical stages per unit height

- More compact for high-throughput operations

Membrane-Based Extraction vs. Mixer Settlers

Membrane-based extraction techniques, such as supported liquid membranes or hollow fiber contactors, offer an alternative approach to traditional liquid-liquid extraction. Comparing these with mixer settlers highlights some interesting contrasts:

Mixer Settlers:

- No membrane fouling issues, leading to more consistent long-term performance

- Capable of handling a wider range of solvent systems

- Easier to clean and maintain in industrial settings

- Better suited for high-throughput applications

Membrane-Based Extraction:

- Potential for higher selectivity in certain applications

- Reduced solvent inventory and lower organic phase losses

- Ability to handle systems with similar densities more effectively

- Potential for process intensification in some cases

Application-Specific Performance: Mixer Settlers in Various Industries

Rare Earth Element Extraction

The extraction and purification of rare earth elements present unique challenges due to their similar chemical properties. Mixer settlers have proven particularly effective in this domain:

- Multi-stage configurations allow for efficient separation of closely related lanthanides

- Adjustable residence times accommodate the slow kinetics often encountered in rare earth separations

- Corrosion-resistant materials (e.g., PTFE-lined units) handle aggressive extractants and acidic conditions

- Real-time monitoring capabilities enable precise control of extraction efficiency

Case studies have shown that mixer settler circuits can achieve high-purity separations of elements like neodymium and dysprosium, critical for advanced magnet production in the renewable energy sector.

Nuclear Fuel Reprocessing

In the nuclear industry, the separation of uranium and plutonium from spent fuel is a critical and highly regulated process. Mixer settlers offer several advantages in this application:

- Modular design allows for easy implementation of safeguards and containment measures

- Precise control over phase ratios and residence times optimizes extraction efficiency

- Robust construction materials (e.g., high-grade stainless steel) withstand radiation exposure

- Multiple stages enable high decontamination factors for product streams

The use of mixer settlers in nuclear fuel reprocessing has been well-established, with facilities worldwide relying on this technology for efficient and safe separations.

Wastewater Treatment and Metal Recovery

In environmental applications, mixer settlers play a crucial role in removing contaminants from wastewater and recovering valuable metals. Their effectiveness in these processes stems from:

- Flexibility in handling varying feed compositions and flow rates

- Ability to integrate with other treatment processes (e.g., precipitation, ion exchange)

- Low shear environment preserves integrity of extractants and minimizes emulsion formation

- Easy retrofitting and scaling for evolving treatment needs

Successful implementations have demonstrated the ability of mixer settlers to achieve high removal efficiencies for heavy metals like copper and zinc, meeting stringent environmental regulations while also enabling resource recovery.

Conclusion

This comparative study has illuminated the unique position of mixer settlers in the landscape of extraction technologies. While each method has its strengths, mixer settlers offer a compelling combination of flexibility, efficiency, and reliability across a wide range of applications. Their ability to handle complex separations, coupled with customizable designs and operational parameters, makes them a versatile choice for many industries. As chemical processes continue to evolve, the adaptability of mixer settlers positions them as a key technology for meeting future separation challenges.

Contact US

Ready to optimize your extraction processes? Cuiyan Technology offers state-of-the-art mixer settler solutions tailored to your specific needs. From rare earth purification to wastewater treatment, our expert team can help you achieve superior separation results. Contact us today at wangzhijun@cuiyan-tec.com to discover how our innovative technology can enhance your operations.