Understanding the Fundamentals of Mixer Settler Technology

The Anatomy of a Mixer Settler Unit

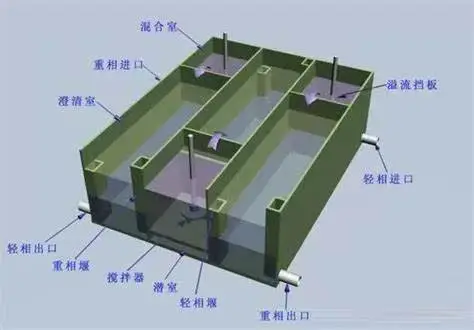

A typical mixer settler unit consists of two main components: the mixing chamber and the settling chamber. The mixing chamber houses an agitator that vigorously blends two immiscible liquids, creating a large interfacial area for mass transfer. This emulsion then flows into the settling chamber, where gravity separates the phases based on density differences. Baffles and weirs in the settler guide the flow and maintain a stable interface between the separated liquids.

Principles of Operation

The operation of a mixer settler revolves around the concept of liquid-liquid extraction. In the mixing stage, solutes are transferred between the two immiscible phases based on their relative solubilities. The settling stage allows for the physical separation of these phases, with the heavier phase settling to the bottom and the lighter phase rising to the top. This process can be repeated in multiple stages to achieve high levels of extraction or purification.

Key Design Considerations

Effective mixer settler design requires careful consideration of several factors. The mixing intensity must be sufficient for thorough phase contact without creating emulsions that are difficult to separate. Settler dimensions need to provide adequate residence time for complete phase separation. Material selection is crucial, with options ranging from polypropylene for corrosive environments to stainless steel for high-temperature applications. Advanced features like adjustable weirs and interface level controls enhance operational flexibility.

Applications and Advantages of Mixer Settler Systems

Diverse Industrial Applications

Mixer settlers find applications across a wide spectrum of industries. In hydrometallurgy, they're used for extracting and purifying metals like copper, nickel, and rare earth elements. The pharmaceutical industry employs them for solvent extraction in drug manufacturing processes. Environmental applications include the removal of contaminants from wastewater streams. Nuclear fuel processing relies on mixer settlers for the separation of uranium and plutonium isotopes.

Advantages Over Other Separation Technologies

Compared to other liquid-liquid extraction technologies, mixer settlers offer several distinct advantages. They provide excellent mass transfer efficiency due to intense mixing, coupled with clear phase separation in the settler. The modular nature of mixer settler units allows for easy scaling and process flexibility. Their simple design translates to lower capital and operating costs compared to complex column extractors. Additionally, mixer settlers can handle a wide range of flow rates and viscosities, making them versatile for various process conditions.

Energy Efficiency and Environmental Considerations

Modern mixer settler designs prioritize energy efficiency and environmental sustainability. Advanced agitator designs reduce power consumption while maintaining mixing effectiveness. Some models incorporate energy recovery systems to utilize the potential energy of flowing liquids. From an environmental perspective, the efficient separation achieved by mixer settlers minimizes solvent losses and reduces waste generation. This not only improves process economics but also aligns with increasingly stringent environmental regulations.

Optimizing Performance and Future Trends in Mixer Settler Technology

Process Optimization Strategies

Maximizing the performance of mixer settler systems involves a multifaceted approach. Fine-tuning the agitation speed and settler residence time can significantly improve extraction efficiency. Implementing feedback control systems allows for real-time adjustments based on process parameters like interface level and phase composition. Advanced computational fluid dynamics (CFD) modeling helps optimize flow patterns and baffle designs, reducing dead zones and improving overall system performance.

Emerging Technologies and Innovations

The field of mixer settler technology continues to evolve with new innovations. Microfluidic mixer settlers are being developed for applications requiring precise control over small volumes, such as in pharmaceutical research. Smart mixer settlers equipped with inline sensors and machine learning algorithms can adapt to changing process conditions autonomously. Novel materials like advanced polymers and composites are expanding the range of chemical compatibilities and operating conditions for mixer settler units.

Future Outlook and Research Directions

Looking ahead, mixer settler technology is poised for further advancements. Research is focused on developing more compact and intensified designs to reduce footprint and increase throughput. Integration with other separation technologies, such as membrane processes, could lead to hybrid systems with enhanced capabilities. As sustainability becomes increasingly important, there's a growing emphasis on designing mixer settlers that minimize solvent usage and energy consumption. The application of artificial intelligence for predictive maintenance and process optimization represents another exciting frontier in the evolution of mixer settler technology.

Conclusion

Mixer settler technology has proven to be a versatile and efficient solution for liquid-liquid extraction across various industries. Its ability to combine intense mixing with effective separation makes it invaluable for processes ranging from metal purification to pharmaceutical production. As we look to the future, ongoing innovations in design, materials, and control systems promise to further enhance the capabilities of mixer settlers, cementing their role as a cornerstone of modern chemical processing. By continuing to optimize and innovate, mixer settler technology will play a crucial part in meeting the evolving challenges of efficient and sustainable chemical separations.

Contact Us

Ready to revolutionize your chemical processes? Cuiyan Technology offers cutting-edge mixer settler solutions tailored to your specific needs. Experience enhanced efficiency, improved product purity, and reduced operational costs. Contact us today at wangzhijun@cuiyan-tec.com to discover how our expertise can transform your operations.