When evaluating purification technologies, mixer settlers stand out as versatile and precise equipment crucial for liquid-liquid extraction. They offer seamless integration in processes requiring the separation of complex mixtures, ensuring high purity and efficiency. Choosing the right mixer settler from an array of configurations demands understanding how their features align with industrial requirements like scalability, compliance, and customization. This article explores mixing settler options in detail, assisting professionals from pharmaceuticals to chemical industries in selecting optimized solutions.

Understanding Mixer Settlers

What is a Mixer Settler?

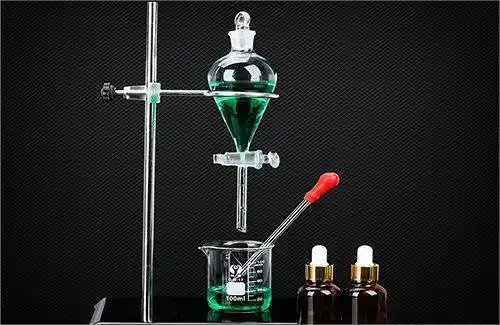

A mixer settler is a specialized device designed to facilitate liquid-liquid extraction by providing two distinct zones: a mixing chamber where immiscible liquids are thoroughly blended and a settling compartment where gravity allows phases to separate. This technology harnesses agitation to promote mass transfer of solutes between phases, followed by quiescent conditions that enable clear phase disengagement. Its modular design, often represented by multiple stages, allows sequential extractions with high efficiency. Industries ranging from pharmaceuticals producing botanical extracts to nuclear processing rely on this adaptability to achieve precise separations.

The internal mechanics can include adjustable agitator speeds and configurable phase interface heights, offering the control needed to maintain consistent extraction conditions. Materials range widely - from corrosion-resistant stainless steel (SUS316L) to transparent polymers like PMMA, enabling real-time observation. These features make mixer settlers remarkably suitable for processes that demand stringent quality standards and gentle handling of delicate compounds.

Advantages and Disadvantages of Mixer Settlers

Mixer settlers bring multiple advantages that address core purification challenges. Among these, the high extraction rates and reliable phase separation ensure minimal product loss and improved yield. The ability to customize stages and operational parameters lends adaptability across diverse applications, from high-throughput essential oil extraction to complex isotopic separations in nuclear industries. The sealed design, including PTFE seals and precise welding, virtually eliminates leakage risks, thus complying with GMP standards and reducing contamination.

On the other hand, mixer settlers may require considerable footprint in facilities with space limitations, and designing rigs for extremely large-scale continuous production can be more complex compared to column extraction technologies. Maintenance demands, including regular cleaning and seal replacement, must be anticipated to sustain long-term operational integrity. Despite these nuances, the operational ease and robust construction often outbalance drawbacks, especially where extraction precision and product purity dominate priorities.

Mixer Settler Applications

Common Industries Using Mixer Settlers

Mixer settlers have ingrained themselves as fundamental equipment in various industrial sectors. In pharmaceuticals and nutraceuticals, researchers and plant managers require high-purity, GMP-compliant systems to extract active botanical compounds reliably - a need perfectly met by adjustable and high-efficiency products. The food and beverage sector also benefits, using mixer settlers to preserve sensitive aromas and flavors within essential oils, spices, and natural colors, ensuring food-grade safety without compromising throughput.

The cosmetics and personal care industry leverages gentle extraction methods, like CO2-assisted separations supported by mixer settlers, preserving bioactive ingredients essential for high-quality skincare and perfumes. Moreover, in chemical and industrial applications, mixer settlers facilitate solvent recovery and high-volume processes in areas like lithium battery recycling or specialty chemical manufacturing. Their versatility is proven essential, handling complex separations from rare earth extraction to wastewater heavy metal removal with efficiency and reliability.

Performance and Efficiency

When considering mixer settlers, understanding their operational efficiency compared to alternative technologies is key for informed selection. Mixer settlers commonly achieve extraction efficiencies exceeding 95%, with throughput customizable through mixing volume options ranging from 200 ml to 3 liters or tailored capacities. Adjustable agitator speeds (100-800 RPM) and stage counts align operational flow with process demands.

The integration of modular stages enabled by precise fabrication techniques – like CNC machining and robotic welding – enhances scalability without compromising process stability. Compared to centrifugal extractors, mixer settlers present advantages in ease of maintenance and lower energy consumption, with innovative designs reducing power use by 15-20% relative to traditional models. Moreover, corrosion-resistant materials such as PTFE and SUS316L allow stable operation across a wide pH spectrum (1-14), critical in diverse chemical environments.

Comparing Mixer Settlers with Other Technologies

Mixer Settler vs. Column

Columns and mixer settlers both aim to separate liquid phases but differ in mechanisms and applications. Mixer settlers excel in processes requiring discrete extraction and settling phases, offering controllable agitation and physical separation in compact modular units. Columns provide a continuous operation with high surface area contact through packing materials or trays, often favoring equilibrium separation rather than mass transfer intensity.

From a maintenance perspective, mixer settlers typically allow easier cleaning and inspection due to their accessible settling tanks and transparent parts. Capital costs vary; while columns may provide economies at large scale, the products afford greater flexibility in adjusting stage numbers and configurations to meet varying throughput demands. This adaptability often results in faster process optimization and reduced downtime.

Mixer Settler vs. Centrifugal Extractor

Centrifugal extractors offer rapid phase separation by applying centrifugal force, allowing continuous processing at high throughput. However, they often entail higher energy consumption and more intricate maintenance protocols compared to mixer settlers. Their mechanical complexity may challenge robustness in demanding chemical environments, leading industries processing corrosive or variable feedstocks to favor the products.

Mixer settlers provide easier adjustability of mixing intensity and phase interface, supporting sensitive extractions of botanical actives or rare earth metals. They also minimize shear stress, preserving delicate compound integrity - critical for cosmetics and nutraceutical sectors. For budget-conscious operations, the products prove cost-effective over lifecycle due to lower wear and simpler part replacement.

Data-driven analyses emphasize:

- Mixer settlers' zero-leak designs and corrosion-resistant materials enable safer operation handling aggressive solvents.

- Centrifugal technologies excel in handling large volumes quickly but lack the customization granularity available in products.

- Modular mixer settlers meet diverse process optimization criteria with energy savings and operational consistency.

The decision depends on process priorities - maintenance agility and product delicacy often tilt preference toward products.

Procurement Considerations for Mixer Settlers

Buying Guide for Mixer Settlers

Acquiring mixer settlers entails a thorough evaluation of technical specifications, facility integration capabilities, and service support. Important considerations include mixing volume options, plate thickness ranging from 5 mm to 10 mm for optimal separation, and construction materials matched to process chemistry (options include PP, PPH, PVC, PMMA, PTFE, PEEK, stainless steel, and titanium).

Additional features such as temperature control devices, pH adjustment units, and anti-overflow tanks enhance operational control and safety. Evaluation frameworks prioritize:

- Customizability of agitator speed, stage number, and interface height to fit evolving process needs.

- Fabrication processes like welding or injection molding ensuring integrity and longevity.

- Vendor support for installation, training, and maintenance documentation.

Aligning procurement with compliance standards (ASME, ISO, REACH) aids regulatory approval and export potential. Selecting the right product partner can drive efficiency gains and reduce long-term operational costs.

Top Mixer Settler Brands and Suppliers

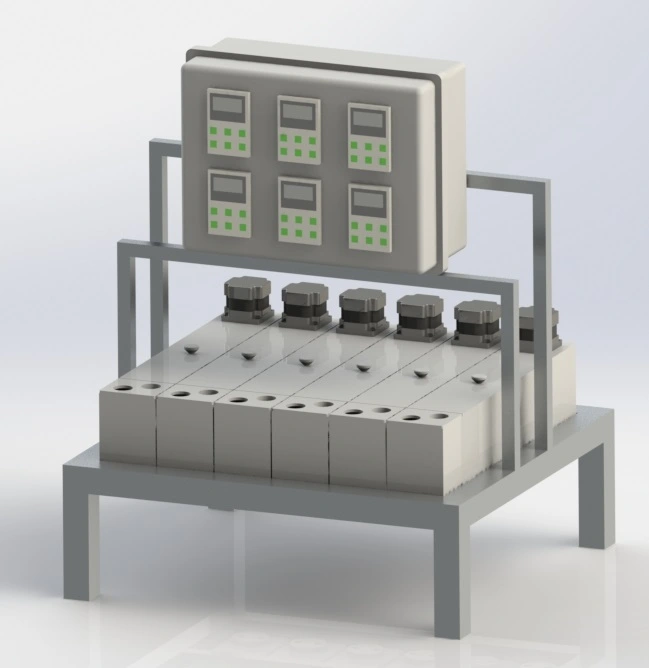

When selecting a manufacturer, industry professionals weigh factors like innovation portfolio, customization capabilities, and proven service excellence. Shaanxi Cuiyan Technology Co., Ltd stands as an exemplary supplier, delivering advanced mixer settler systems since 2012. Their integration of automation, modular construction, and corrosion-resistant materials supports diverse purification needs in rare earth extraction, lithium battery recycling, and beyond.

Testimonials emphasize Shaanxi Cuiyan's highly customizable workflows, intuitive control interfaces, and rigorous zero-leak design. Their commitment to global quality standards ensures compatibility with international projects, fostering trust among pharmaceutical, food, and chemical industry partners. Industry reports highlight their patented baffle designs that stabilize phase separation and sensor integration for real-time monitoring - elements crucial for sustaining process integrity.

Partnering with experienced suppliers like Shaanxi Cuiyan guarantees access to tailored extraction solutions tuned to precise process parameters, supported by expert consultation and robust after-sales support.

Company Introduction and Product/Service Information

Shaanxi Cuiyan Technology Co., Ltd specializes in the research, development, and manufacturing of advanced extraction equipment. Their portfolio includes mixer settlers configured for desktop base editions to environmentally friendly high-performance models with mixing volumes customizable from 200 ml up to 3 liters or tailored capacities. Plates vary in thickness from 5 to 10 mm, fabricated from a diverse palette of materials designed for corrosion resistance and structural strength.

Production methods range from precision welding and bonding to injection molding and integral forming. Optional functions enhance process control, including temperature regulation, pH adjustment, water-bath jackets, anti-overflow tanks, and observation windows. Such comprehensive features offer these advantages:

- High extraction yields and near-perfect phase separation delivering superior purification results.

- Zero leakage risk combined with sturdy, aesthetically refined construction facilitating reliable and easy operation.

- Fine electro-mechanical control - adjusting agitator speed, stage count, and phase interface height - enabling tailored performance.

Shaanxi Cuiyan's decades of expertise, supported by over 100 patents and a team of 37 experts, has produced extraction systems employed in a spectrum of applications, including rare earth element purification, nuclear fuel reprocessing, lithium battery recycling, and biological wastewater management.

Conclusion

Selecting the right mixer settler is pivotal for industries aiming to optimize purification processes while upholding quality and compliance. Shaanxi Cuiyan Technology Co., Ltd offers highly customizable, efficient, and reliable mixer settlers supported by decades of industry experience and innovation. Their solutions not only meet operational demands across pharmaceuticals, food, cosmetics, and chemical sectors but also promote sustainable, scalable extractions with minimized downtime and environmental impact.

FAQs

What are the main components of a mixer settler?

Mixer settlers primarily consist of a mixing chamber where immiscible liquids are vigorously agitated to promote mass transfer, a settling tank where gravitational separation occurs, and peripheral equipment such as pumps. Adjustable weirs and phase interface height controls aid optimal performance, while the construction materials protect against corrosion and ensure durability.

How does a mixer settler improve purification efficiency?

By creating controlled mixing conditions and a quiescent settling zone, mixer settlers optimize the transfer of target solutes between phases, minimizing cross-contamination and maximizing yield. The modular stage design allows for sequential extractions, improving purification quality and reducing solvent consumption compared to single-stage methods.

What maintenance is required for optimal mixer settler performance?

Regular cleaning with deionized water post-operation, routine inspection and replacement of seals, and calibration of agitator speeds and sensor systems are essential. Annual servicing of mechanical parts and vigilance for any leaks or corrosion maintains continuous efficiency and prolongs equipment lifespan.

Where to Buy Mixer Settler?

Shaanxi Cuiyan Technology Co., Ltd presents itself as a premier source for advanced mixer settlers tailored to stringent purification requirements. Their product lines include desktop base editions, mobile units, and environmentally friendly high-efficiency setups with customizable specifications to suit varied industrial processes. Interested professionals are encouraged to contact the company directly to discuss detailed requirements and explore custom solutions. Reach out via email at wangzhijun@cuiyan-tec.com to initiate a consultation with expert representatives and discover how Shaanxi Cuiyan's mixer settlers can elevate your production capabilities.

References

King, C. J. "Separation Processes." McGraw-Hill, 1980.

Treip, C., and Nidiry, R. "Advances in Liquid-Liquid Extraction Technology." Chemical Engineering Journal, 2015.

Smith, R. "Chemical Process Design and Integration." Wiley, 2005.

Gupta, R., and Kumar, S. "Optimizing Mixer Settler Parameters for Rare Earth Recovery." Separation Science and Technology, 2018.

Patel, D., and Scott, M. "Sustainable Extraction Methods for Botanical Compounds." Journal of Pharmaceutical Sciences, 2020.

Martinez, L. "Comparative Study of Mixer Settlers and Centrifugal Extractors in Industrial Applications." Industrial & Engineering Chemistry Research, 2017.