Understanding Lab Scale Mixer Settler Technology

Principles of Operation

Lab-scale mixer settlers utilize differences in liquid densities to achieve separation between immiscible phases. In the mixing chamber, intense agitation created by rotating impellers enhances interfacial contact, facilitating efficient mass transfer of solutes from one phase to the other. The resulting emulsion then transitions into the settling chamber, where gravitational forces promote phase disengagement. Here, adjustable baffles and weirs help maintain a stable interface level while regulating flow velocity and residence time. This controlled separation process allows for consistent performance and high extraction efficiency, making the system particularly useful for continuous small-scale liquid-liquid extraction processes.

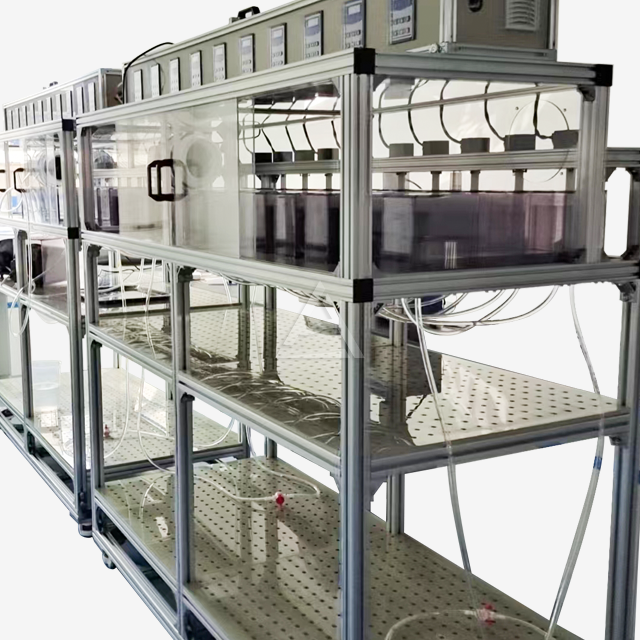

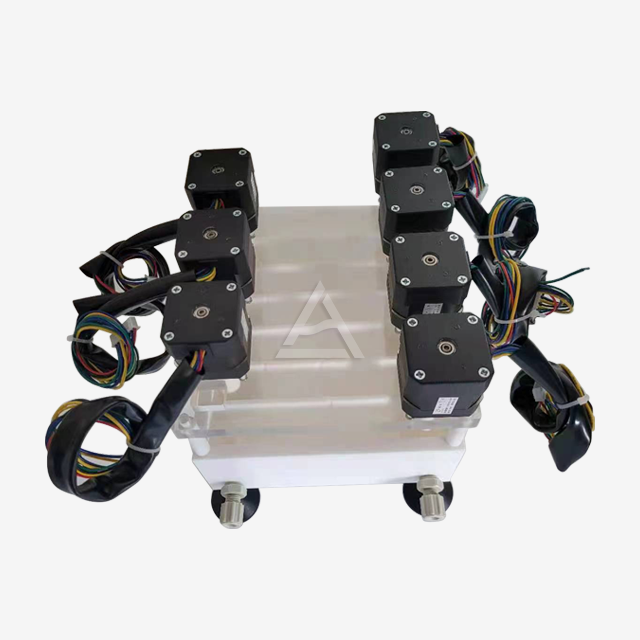

Key Components and Design Features

Modern lab mixer settlers integrate several critical components designed to improve functionality and user control. These include precision-engineered impellers that generate reproducible mixing intensity, transparent acrylic sections for real-time visual monitoring of phase dispersion and separation, and integrated sensors for tracking parameters such as pH, temperature, and interface level. Additional elements such as anti-overflow mechanisms prevent accidental cross-contamination or loss of valuable samples, while modular design supports flexible multi-stage configurations. These features collectively enhance operational reliability and facilitate more accurate process scaling from bench-level experiments to pilot systems.

Advantages Over Other Extraction Methods

Compared to conventional techniques such as separatory funnels or batch extraction systems, lab mixer settlers provide significant benefits in terms of efficiency and process control. Their continuous operational capability reduces downtime and improves throughput, while engineered mixing enhances mass transfer rates through optimal droplet formation. The designed settling chambers allow sharper phase separation with minimal entrainment. Furthermore, the system offers improved scalability, enabling direct translation of laboratory results to larger industrial processes. Automation options also reduce manual intervention, thereby lowering contamination risks and increasing reproducibility in sensitive applications.

Material Selection and Compatibility Considerations

Chemical Resistance of Common Materials

The selection of chemically compatible materials is critical to ensuring the long-term functionality and reliability of laboratory mixer settlers. PTFE (polytetrafluoroethylene) stands out due to its near-universal resistance to aggressive solvents, acids, and bases, making it ideal for highly corrosive applications. PVC (polyvinyl chloride) offers an economical alternative for less demanding conditions and allows visual monitoring through transparent variants. SUS316L stainless steel provides mechanical strength and good corrosion resistance, particularly against chlorides, while facilitating easy cleaning and sterilization. PEEK (polyether ether ketone) is valued for its ability to withstand high temperatures and resist a wide range of organic solvents, contributing to both safety and operational flexibility in complex extraction processes.

Impact of Material Choice on Extraction Efficiency

Material selection in lab scale mixer settler directly affects extraction performance beyond mere equipment durability. The surface wettability of the material can influence phase separation efficiency and emulsion formation. Leaching of additives or ions from certain plastics or metals may contaminate sensitive samples, compromising purity. Thermal conductivity also plays a role in temperature-sensitive processes, where inefficient heat transfer could alter kinetics or recovery rates. Furthermore, optical clarity in materials like glass or transparent polymers enables real-time monitoring and analysis, supporting better process control and reproducibility in multiphase systems.

Specialized Coatings and Surface Treatments

Advanced surface treatments significantly enhance mixer settler performance under challenging conditions. Fluoropolymer coatings extend chemical resistance to materials otherwise susceptible to degradation. Electropolishing stainless steel surfaces reduces roughness, minimizing product adhesion and simplifying cleaning. Hydrophobic surface treatments help prevent unwanted carryover of aqueous phases into organic streams, improving separation accuracy. Anti-fouling coatings further reduce scaling and particulate buildup, maintaining consistent operational efficiency and reducing downtime in continuous processes.

Customization and Scalability Features

Adjustable Parameters for Process Optimization

Versatile lab mixer settlers offer numerous tunable variables:

- Agitation speed control (typically 50-800 RPM)

- Residence time adjustment through baffle positioning

- Interface level regulation via weir height modification

- Temperature control through integrated heating/cooling jackets

- pH monitoring and adjustment capabilities

Modular Designs for Multi-Stage Extraction

Scalable mixer settler systems allow researchers to:

- Connect multiple units in series for counter-current extraction

- Easily add or remove stages to optimize separation

- Evaluate different flow configurations (e.g., cross-flow, co-current)

- Simulate industrial-scale processes at the laboratory level

Integration with Data Acquisition Systems

Modern lab mixer settlers often feature:

- Digital interfaces for precise parameter control

- Data logging capabilities compatible with laboratory software (e.g., LabView)

- Real-time monitoring of critical process variables

- Remote operation options for automated experimental runs

- Integration with LIMS (Laboratory Information Management Systems) for streamlined workflow

Conclusion

Choosing the right lab scale mixer settler is a critical decision that can significantly impact research outcomes and process development efficiency. By carefully considering factors such as material compatibility, customization options, and scalability features, researchers can select a system that meets their current needs while providing flexibility for future applications. High-quality lab mixer settlers offer precise control over extraction parameters, enabling optimization at the bench scale before committing to larger pilot or industrial-scale operations.

Contact Us

Elevate your liquid-liquid extraction research with Cuiyan Technology's advanced lab scale mixer settlers. Our patented designs ensure superior extraction rates and unmatched flexibility. Contact us atwangzhijun@cuiyan-tec.com to discuss how our customizable solutions can accelerate your R&D efforts.