Understanding the Mixer Settler Technology

The Anatomy of a Mixer Settler

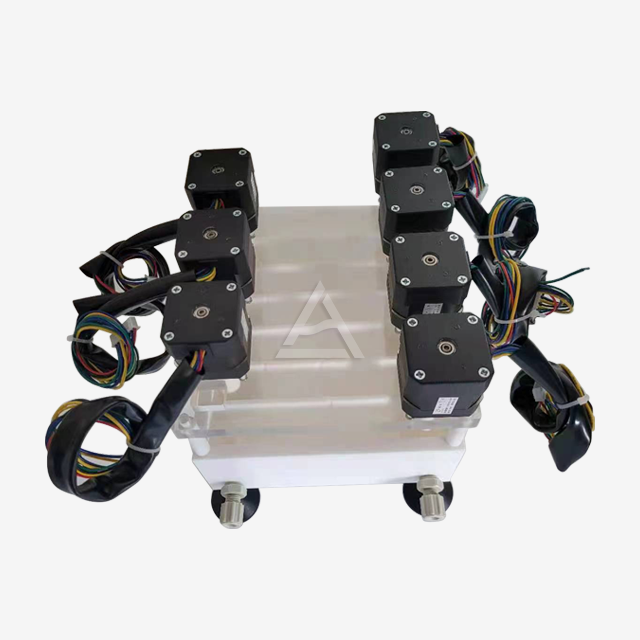

Mixer settlers are ingeniously designed separation units that consist of two main compartments: the mixer and the settler. The mixer section is where the magic begins. Here, an agitator vigorously blends two immiscible liquids, creating a dispersion that promotes mass transfer between the phases. This mixing action is crucial for extracting desired compounds from one phase into another.

Following the mixer, we have the settler section. This is where gravity takes over, allowing the mixed phases to separate based on their density differences. The settler is designed with baffles and weirs that guide the flow and maintain a stable interface between the separated phases. This careful engineering ensures that the two liquids exit the unit cleanly separated, ready for the next stage of processing or collection.

The Science Behind the Separation

The effectiveness of mixer settlers lies in their ability to harness fundamental principles of chemistry and physics. Liquid-liquid extraction, the core process at work, relies on the different solubilities of compounds in two immiscible liquids. By choosing the right combination of solvents and adjusting operating parameters, we can selectively extract target molecules from complex mixtures.

The mixing stage creates a large interfacial area between the two liquids, accelerating the mass transfer of solutes. Factors such as agitation speed, temperature, and pH can be fine-tuned to optimize this transfer. In the settling stage, the difference in density between the phases drives separation, with lighter components rising to the top while heavier ones sink.

Customization and Flexibility

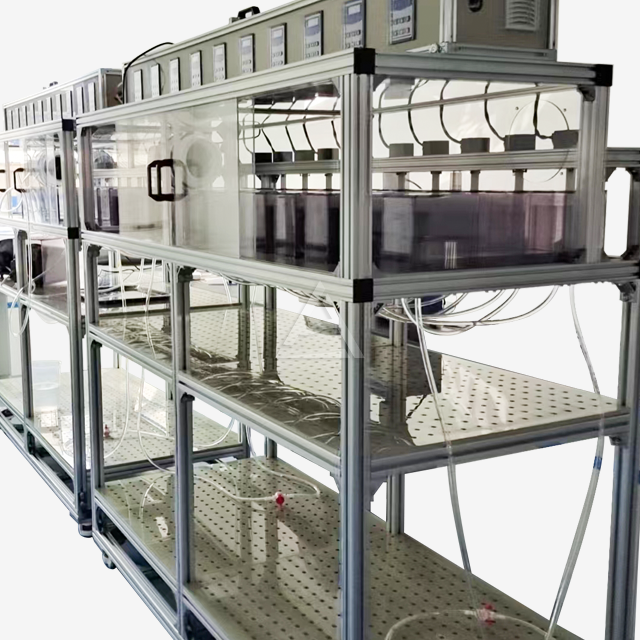

One of the most compelling aspects of mixer settler technology is its adaptability. These units can be tailored to meet specific process requirements. The mixing volume can range from a modest 200ml to a substantial 3L, or even be custom-designed for unique applications. Plate thickness options (5mm, 6mm, 8mm, 10mm) allow for different levels of structural integrity based on the corrosiveness or pressure of the fluids being handled.

Material selection is another crucial aspect of customization. Depending on the chemical environment, mixer settlers can be constructed from a variety of materials including PP, PVC, PMMA, PTFE, and even exotic alloys like titanium for extreme conditions. This flexibility ensures that mixer settlers can be deployed in diverse industries, from nuclear processing to food-grade extractions.

Applications Across Industries

Rare Earth Element Extraction

In the realm of rare earth element extraction, mixer settlers have become indispensable tools. These devices excel in separating valuable elements like neodymium and dysprosium from complex ore matrices. The process begins with leaching, where the rare earth-containing ore is dissolved in an aqueous solution. This solution then enters a series of mixer settler stages.

In each stage, the aqueous phase is mixed with an organic solvent specifically chosen to selectively extract the desired rare earth elements. The mixer ensures thorough contact between the phases, while the settler allows for clean separation. By carefully controlling pH, temperature, and phase ratios, operators can achieve high purity separations, often recovering over 99% of the target elements.

Battery Recycling and Metal Recovery

As the world shifts towards electric vehicles and renewable energy storage, the demand for efficient battery recycling technologies has skyrocketed. Mixer settlers play a crucial role in this emerging field, particularly in recovering valuable metals like lithium and cobalt from spent batteries.

The process typically involves first mechanically breaking down the batteries and leaching the metals into an aqueous solution. This solution is then fed into a mixer settler system where specific organic extractants are used to selectively remove lithium and cobalt. The multi-stage nature of mixer settlers allows for high purity recovery, with each stage refining the separation further. This not only reduces waste but also provides a sustainable source of critical battery materials.

Wastewater Treatment and Environmental Applications

In the battle against water pollution, mixer settlers are proving to be formidable allies. These units are particularly effective in removing heavy metals and other contaminants from industrial wastewater. For instance, in treating copper-containing waste streams, a series of mixer settlers can be employed to extract copper ions using specialized chelating agents.

The process begins with pH adjustment in the mixer to optimize extraction conditions. As the solution flows through multiple stages, copper is progressively removed, leaving behind cleaner water. The extracted copper can then be recovered from the organic phase, often through electrowinning, creating a circular economy approach to waste management. This application of mixer settlers not only helps industries meet stringent environmental regulations but also recovers valuable resources that would otherwise be lost.

Optimizing Mixer Settler Performance

Key Design Considerations

Achieving peak performance from mixer settlers requires careful attention to design details. One critical factor is the mixer-to-settler volume ratio. Typically, the settler volume is 2-3 times larger than the mixer to ensure adequate separation time. The shape of the settler is also crucial, with sloped bottoms facilitating phase separation and preventing dead zones where particles might accumulate.

Baffle design within the settler is another area where innovation can lead to significant improvements. Advanced baffle configurations can enhance phase separation by promoting laminar flow and reducing turbulence at the interface. Some designs incorporate coalescence-promoting materials to accelerate droplet formation and separation.

Process Control and Automation

Modern mixer settler operations benefit greatly from advanced process control systems. Real-time monitoring of key parameters such as flow rates, interface levels, and phase compositions allows for dynamic adjustments to maintain optimal performance. PLC-based control systems can integrate data from multiple sensors, including pH probes, conductivity meters, and optical sensors, to provide a comprehensive view of the extraction process.

Automated sampling and analysis systems can be incorporated to provide continuous feedback on extraction efficiency and product purity. This data-driven approach not only improves consistency but also allows for predictive maintenance, reducing downtime and extending equipment life.

Enhancing Efficiency and Sustainability

As industries strive for greater sustainability, mixer settler technology is evolving to meet these demands. Energy efficiency is a key focus, with newer designs incorporating features like variable speed drives for agitators, allowing power consumption to be optimized based on process requirements. Some advanced systems even recover energy from the fluid flow between stages, further reducing overall energy costs.

Water conservation is another area where mixer settlers are making strides. Closed-loop systems that recycle process water and innovative solvent recovery techniques are helping to minimize the environmental footprint of extraction operations. Additionally, the development of bio-based and environmentally friendly extractants is opening up new possibilities for green chemistry applications in mixer settler technology.

Conclusion

Mixer settlers represent a pinnacle of efficiency in separation technology, offering unparalleled versatility across numerous industries. From rare earth extraction to wastewater treatment, these devices continue to prove their worth through high extraction rates, perfect separation effects, and adaptability to diverse chemical environments. As we've explored, the key to their success lies in the careful balance of mixing dynamics and gravitational separation, coupled with the ability to fine-tune operational parameters. With ongoing advancements in materials, design, and process control, mixer settlers are poised to play an even more significant role in addressing future industrial and environmental challenges.

Contact Us

Ready to revolutionize your separation processes? Cuiyan Technology offers cutting-edge mixer settler solutions tailored to your specific needs. Experience the benefits of high efficiency, customizability, and expert support. Contact us today at wangzhijun@cuiyan-tec.com to discover how our mixer settler technology can transform your operations.