When sourcing extraction equipment for chemical processing, industry professionals seek reliable, high-performance systems that deliver precision and scalability. Extraction equipment is critical for separating valuable components from complex mixtures, ensuring consistent quality and compliance across pharmaceuticals, food and beverage, cosmetics, and industrial sectors. Leading suppliers provide cutting-edge solutions designed to optimize throughput, maintain regulatory standards, and reduce environmental impact. This article explores key suppliers renowned for their innovative extraction systems, including liquid extraction options by Shaanxi Cuiyan Technology Co., Ltd., a trusted manufacturer dedicated to customization, efficiency, and long-term support.

Understanding Extraction Equipment

What is Extraction Equipment?

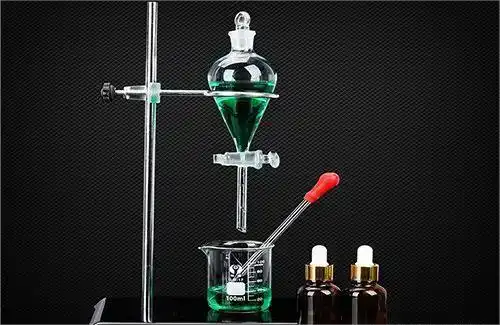

Extraction equipment refers to the machinery used to separate desired substances from raw materials or mixtures through physical or chemical means. This equipment often includes vessels, mixers, separators, and control units, designed specifically for processes like liquid-liquid extraction, solvent extraction, or mechanical pressing. Extraction systems play a foundational role in diverse industries - from isolating active botanical compounds in pharmaceuticals to recovering metals in industrial recycling. Key components such as mixer-settlers, centrifugal extractors, and extraction towers facilitate stable phase separation and efficient compound recovery. Understanding these elements is essential before selecting or investing in appropriate equipment.

How Does Extraction Equipment Work?

Extraction equipment operates based on principles such as solubility differences, density variations, and selective mass transfer between phases. Typically, the process begins with mixing two immiscible liquids - one containing the target compound and a solvent - enhanced by adjustable agitators. After intimate contact, the mixture proceeds to settling zones where gravity or centrifugal forces separate phases, enabling collection of purified extracts. Parameters like mixing volume, agitator speed, mixer-settler stages, and phase interface height are meticulously controlled for optimal efficiency. Integration of temperature and pH control devices further refines extraction precision. Visual aids like flowcharts can clarify these stages for process engineers.

Types of Extraction Equipment

Common Types of Extraction Equipment

Two predominant categories dominate chemical processing extraction: solvent extraction equipment and mechanical extraction equipment. Solvent extraction systems utilize liquid solvents to selectively dissolve compounds, commonly applied in pharmaceuticals for botanical extracts and metal recovery. Mechanical extraction employs physical methods such as pressing or milling to separate substances, prevalent in food and beverage industries for essential oils and flavors. Each method addresses different operational needs - solvent extraction excels in purity and complexity, while mechanical extraction offers simplicity and speed. Comparative analyses help facilities determine the best fit based on throughput requirements and product specifications.

Specialized Extraction Equipment

Specialized extraction equipment caters to niche industrial challenges, incorporating innovations like centrifugal extractors for high-volume solvent recovery or box-type extraction tanks suitable for precious metal recycling. Advanced materials (e.g., PTFE, SUS) and manufacturing techniques (welding, injection molding) ensure chemical resistance and system longevity. Customized configurations - including desktop to industrial-scale options - support diverse workflows, from laboratory pilot programs to full-scale hydrometallurgical production lines. Implementing temperature-controlled jackets, anti-overflow tanks, and real-time monitoring sensors enhances operational control in demanding environments such as nuclear extraction or battery recycling sectors.

Benefits and Features of Extraction Equipment

Advantages of Using Extraction Equipment

Employing extraction equipment significantly boosts chemical processing through enhanced efficiency and improved product quality. Automation and precise control minimize human error and reduce waste, aligning manufacturing with stringent GMP and food-grade safety standards. Environmental benefits arise via solvent recovery and energy-saving system designs that lower carbon footprints. Safe construction materials and leak-proof engineering protect workers and reduce hazards associated with chemical handling. Ultimately, this technology accelerates scalability and repeatability, vital for pharmaceutical and nutraceutical R&D and commercial production alike.

Key Features to Consider

When selecting extraction equipment, durability and reliability stand out as critical features to prevent downtime and costly repairs. Material choices such as corrosion-resistant alloys and FDA-compliant polymers enable operation with aggressive chemicals while maintaining product purity. Adjustable mixer-settler stages and agitator speeds allow fine-tuning for varied extraction tasks. Additional options, including temperature and pH regulation, anti-bubbling technology, and integrated liquid level monitoring, ensure consistent processing outcomes. Evaluating cost versus added value requires attention to system modularity and long-term service support, as upfront investment often pays dividends in productivity and compliance.

Comparison and Decision-Making

Comparing Extraction Equipment Options

Reviews and comparisons of extraction equipment reveal that no single model fits all industry demands. Systems from market leaders like Bühler, GEA, and Andritz offer robust solutions with proven track records, while specialized providers like Shaanxi Cuiyan emphasize customizability and niche applications. Pros and cons vary by factors such as throughput capacity, automation level, and adaptability to harsh chemicals. User testimonials highlight the importance of responsive technical support and easy integration into existing operations. Side-by-side feature matrices and case study summaries assist in pinpointing the ideal setup for specific extraction goals.

Decision-Making Criteria

Selecting appropriate extraction equipment involves weighing production scale, industry-specific regulatory requirements, and budget constraints. Key considerations include the system’s compliance certifications (e.g., GMP, FDA), flexibility for future process changes, and energy efficiency. Process compatibility, such as suitability for rare earth elements, bio-waste recycling, or natural product extraction, ensures operational longevity. Procurement decisions benefit from input across R&D, plant management, and maintenance teams, fostering alignment on technical specifications and anticipated return on investment.

Top Suppliers of Extraction Equipment

Leading Brands and Manufacturers

Market-leading extraction equipment suppliers differentiate themselves through innovation, quality certifications, and global service networks. Shaanxi Cuiyan Technology Co., Ltd. has firmly established itself with over a decade of experience providing liquid extraction systems tailored for lab to industrial applications. Their portfolio encompasses box-type tanks, tubular extractors, and centrifugal units designed with modularity and sustainability in mind. Certification adherence and real-world client success stories underpin these firms' reliability in complex chemical processing environments.

Supplier Evaluation and Selection

Choosing the best extraction equipment supplier depends on comprehensive evaluation criteria: product quality, customization capabilities, after-sale support, and proven project success. Shaanxi Cuiyan's collaborative approach ensures each client receives bespoke solutions matched to processes involving rare earth metals, battery recycling, or bio-waste treatment. Case studies reveal significant gains in extraction efficiency (often surpassing 95%) and operational uptime facilitated by their patented anti-bubbling strategies and automated controls. Regular training and technical advisory services enhance customer confidence and drive continuous improvement.

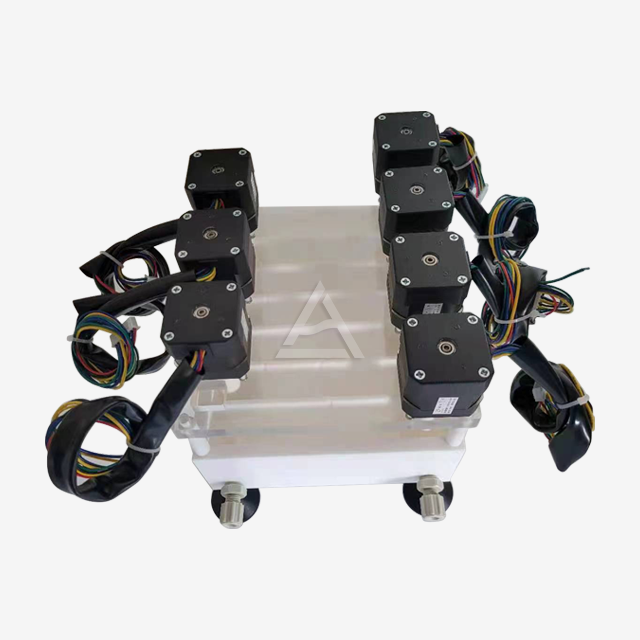

Shaanxi Cuiyan Extraction Equipment Solutions

Since 2012, Shaanxi Cuiyan Technology Co., Ltd has delivered laboratory to pilot-scale liquid extraction equipment notable for precision, durability, and versatility. Their desktop base edition and environmentally friendly high edition accommodate mixing volumes from 200ml to 3 liters, using high-quality materials such as SUS316L, PTFE, and biocompatible polymers. Production processes like welding, injection molding, and CNC bending guarantee tight seals with no leakage risk. The equipment's user-friendly interface supports adjustable mixer stages, agitation speeds, and phase interface heights, ensuring tailored separations across applications including rare earth recovery and lithium battery recycling.

Here are the core advantages of this device:

- High extraction efficiency exceeding 95%, optimizing raw material utilization and throughput

- Perfect phase separation achieved via anti-bubbling technology and stable settling zones

- Durability ensured through corrosion-resistant materials suitable for harsh chemical environments

- Highly customizable configurations supporting optional functions like temperature and pH control

- Easy operation and maintenance backed by comprehensive customer service

These advantages can effectively solve production challenges such as leakage, low extraction yields, and scalability hurdles faced by R&D labs and industrial manufacturers.

Conclusion

Choosing the right supplier for extraction equipment is pivotal for optimizing chemical processing workflows across various industries. Companies like Shaanxi Cuiyan Technology Co., Ltd excel by combining advanced engineering, customizable solutions, and proven process expertise. Their liquid extraction equipment supports a wide range of critical applications from pharmaceutical extracts to metal recycling, delivering consistent high-quality separation and operational reliability. By focusing on precision, compliance, and customer-centric service, suppliers can empower R&D and production teams to meet both present challenges and future innovations.

FAQs

What are the maintenance tips for extraction equipment?

Routine inspections to detect wear or corrosion, regular cleaning to prevent residue buildup, and calibration of sensors enhance longevity and consistent performance. Adhering to manufacturer-recommended safety protocols safeguards operators and equipment integrity.

How does extraction equipment compare to traditional methods?

Modern extraction systems provide superior extraction efficiencies with less solvent use and energy consumption. Automation and closed-loop designs reduce environmental impact compared to manual batch processing while ensuring repeatable outcomes.

What are the financing and leasing options for extraction equipment?

Many suppliers offer flexible financing plans including installment payments and leasing options. These alternatives allow businesses to access advanced machinery without large upfront capital expenditures, facilitating technology upgrades aligned with production growth.

Where to Buy Extraction Equipment?

To acquire extraction equipment tailored to your chemical processing needs, consider partnering with Shaanxi Cuiyan Technology Co., Ltd, a premier manufacturer renowned for their innovative and customizable solutions. Their expertise spans lab-to-industrial scale systems, ensuring quality and scalability. Reach out for consultations or inquiries regarding product specifications and services by contacting us at wangzhijun@cuiyan-tec.com. Discover how our cutting-edge extraction equipment can enhance your operational efficiency and compliance.

References

Smith, J. & Lee, A. (2020). Advances in Liquid Extraction Technology for Chemical Processing. Journal of Chemical Engineering.

Brown, M. et al. (2019). Industrial Applications of Mixer-Settler Extraction Equipment. AIChE Symposium Series.

Wilson, K. & Johnson, R. (2021). Materials and Design Considerations for Extraction Equipment in the Pharmaceutical Sector. Pharmaceutical Technology Review.

Anderson, P. (2018). Sustainable Solvent Extraction Techniques in Food and Beverage Manufacturing. Food Processing Journal.

Chen, L. & Davies, S. (2022). Modular Extraction Systems: Enhancing Flexibility in Chemical Recycling. Chemical Industry Digest.

Garcia, F. et al. (2023). Innovations in Battery Recycling Extraction Technologies. Journal of Environmental Chemistry.