Advancements in Mixer Settler Technology

Innovative Design Features

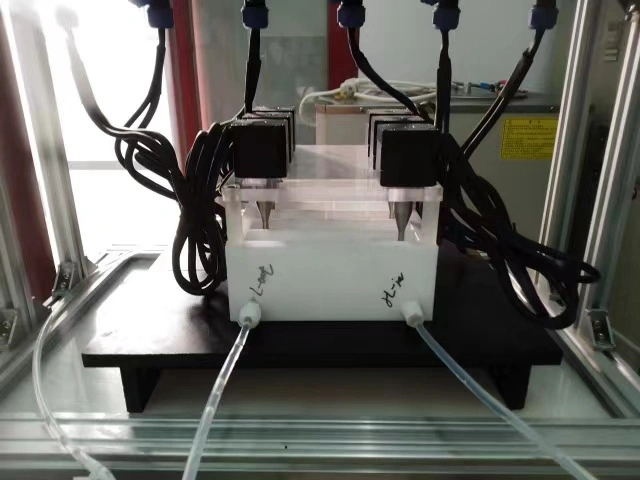

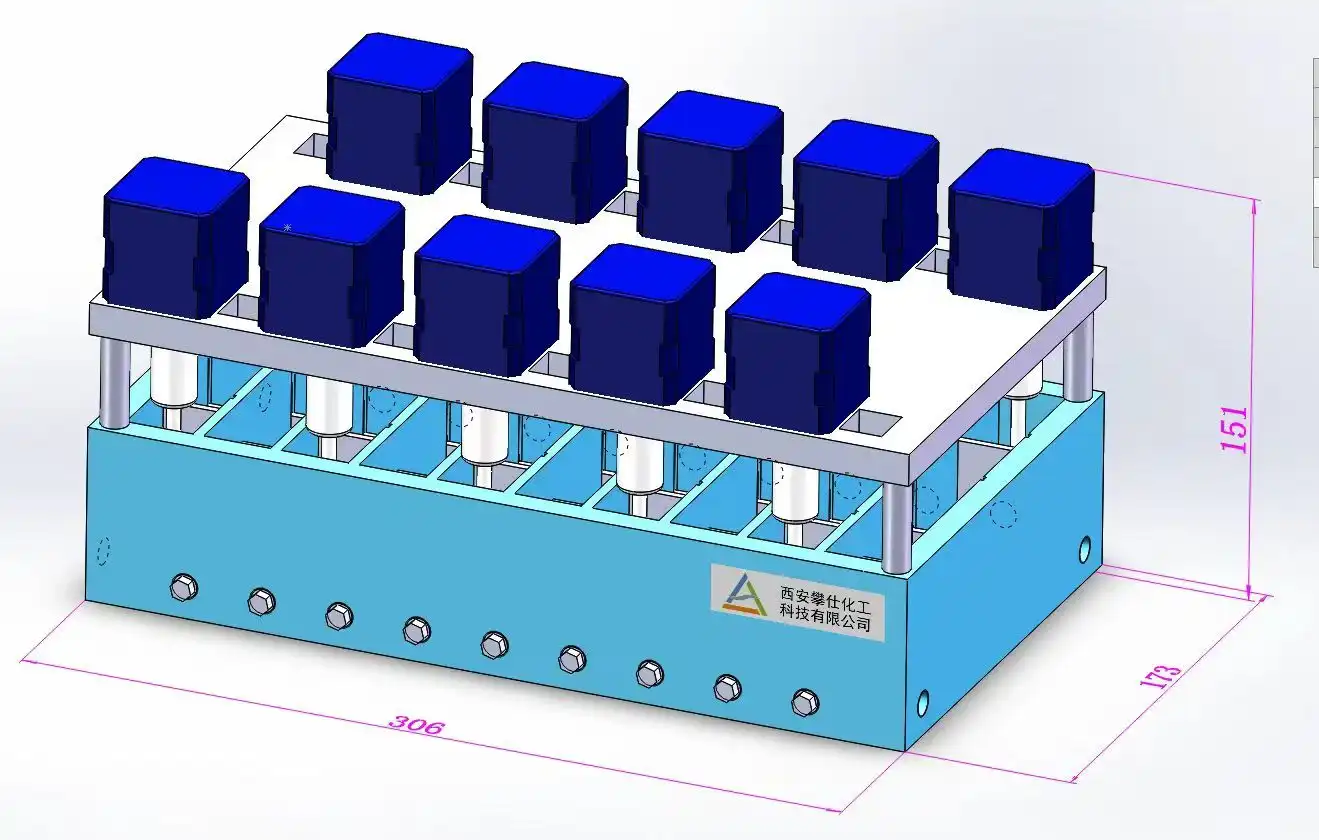

Modern mixer settlers have undergone significant design improvements to enhance their performance and versatility. Manufacturers now offer customizable configurations, including desktop base editions for laboratory use and environmentally friendly high editions for industrial applications. The mixing volume ranges from 200ml to 3L, with options for customization to suit specific process requirements. Plate thickness variations (5mm to 10mm) and a wide selection of materials (PP, PVC, PMMA, PTFE, SUS, Ti) allow for tailored solutions to handle diverse chemical environments.

Advanced fabrication techniques such as precision welding, bonding, and injection molding ensure structural integrity and leak-free operation. The integration of optional features like temperature control devices, pH adjustment mechanisms, and water-bath jackets further expands the capabilities of these systems. Anti-overflow tanks and watch windows add layers of safety and process monitoring, crucial for handling sensitive or hazardous materials.

Enhanced Separation Efficiency

The core advantage of modern mixer settlers lies in their high extraction rates and superior separation effects. Adjustable parameters such as agitator speed, phase interface height, and the number of stages allow operators to fine-tune the process for optimal results. This flexibility is particularly valuable when dealing with complex mixtures or when purity requirements are stringent.

Patented baffle designs have been introduced to prevent bubbling, ensuring stable phase separation even under challenging conditions. This innovation, combined with precision-engineered weirs, contributes to the mixer settler's ability to handle a wide range of liquid-liquid extraction tasks efficiently. The result is a purification process that achieves high product purity with minimal energy input and reduced processing time.

Integration of Smart Technologies

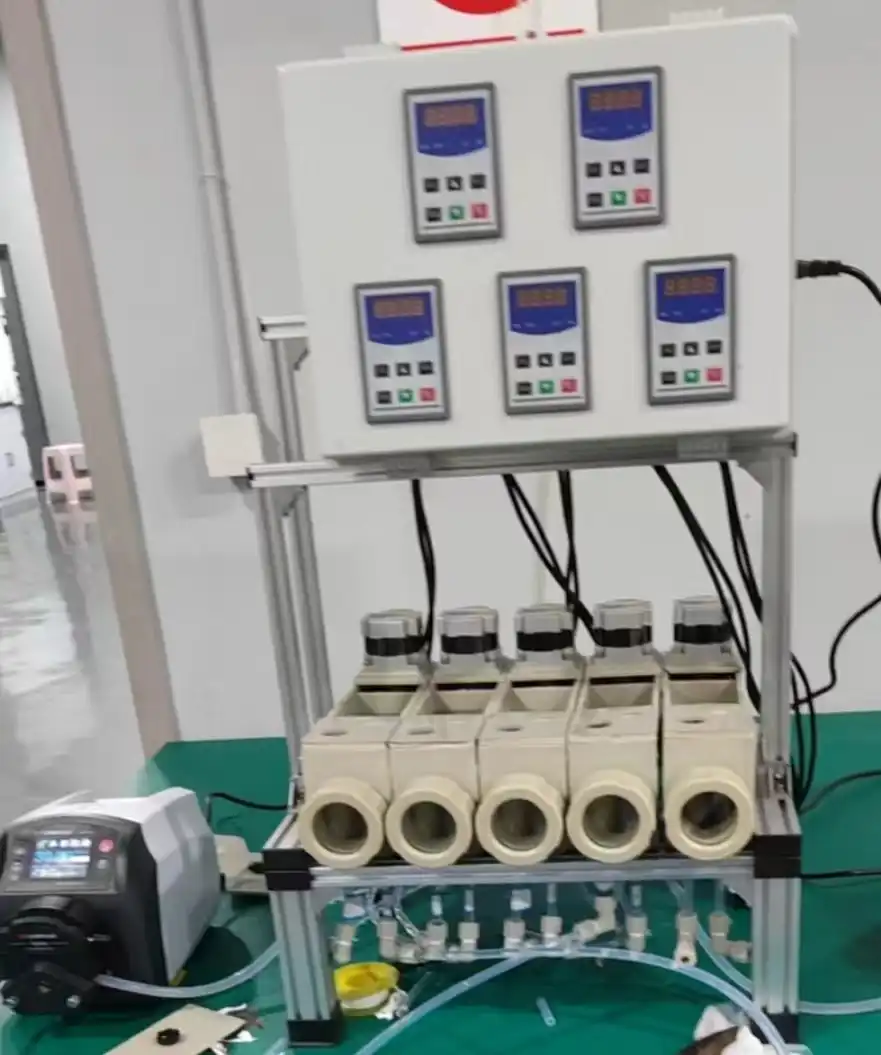

The latest generation of mixer settlers incorporates smart technologies to enhance control and monitoring capabilities. Sensor integration allows for real-time tracking of critical parameters such as pH, temperature, and liquid levels. These data points can be fed into programmable logic controllers (PLCs), enabling automated adjustments and maintaining optimal operating conditions throughout the extraction process.

Energy efficiency has also been a focus of recent developments. Modular designs and optimized flow patterns have resulted in power consumption reductions of 15-20% compared to traditional models. This not only lowers operational costs but also aligns with global sustainability initiatives. Furthermore, compliance with international standards such as ASME, ISO, and REACH ensures that these advanced mixer settlers can be deployed in cross-border projects, meeting the stringent requirements of global industries.

Applications Across Diverse Industries

Rare Earth Element Extraction

The purification of rare earth elements like neodymium and dysprosium has become increasingly critical in the production of high-performance magnets for electric vehicles and advanced electronics. Mixer settlers play a pivotal role in this process, enabling the separation of these valuable elements from complex ore matrices. The multi-stage capability of mixer settlers allows for the implementation of sophisticated extraction sequences, resulting in high-purity rare earth products.

In a typical rare earth purification process, crushed ore undergoes initial leaching to create a mixed rare earth solution. This solution is then fed into a series of mixer settlers, where organic solvents selectively extract specific rare earth elements. The ability to precisely control mixing intensity and settling time in each stage ensures optimal mass transfer and phase separation. As the mixture progresses through the system, impurities are progressively removed, and individual rare earth elements are isolated. This level of separation precision was previously unattainable with conventional methods, making mixer settlers indispensable in meeting the growing demand for high-purity rare earth materials.

Battery Recycling and Resource Recovery

The surge in electric vehicle adoption has brought the challenge of battery recycling to the forefront of environmental concerns. Mixer settlers have emerged as a key technology in recovering valuable materials such as lithium and cobalt from spent batteries. The process begins with the mechanical dismantling of battery packs, followed by chemical leaching to dissolve the target metals. Mixer settlers then come into play, facilitating the selective extraction and purification of these critical elements.

In lithium-ion battery recycling, mixer settlers enable the separation of lithium, cobalt, and other valuable metals through a series of solvent extraction steps. The ability to handle large volumes continuously makes this technology particularly suited for industrial-scale recycling operations. By recovering these materials efficiently, mixer settlers contribute to the circular economy, reducing the need for primary mining and minimizing the environmental impact of battery production. This application showcases how mixer settlers are not only advancing purification processes but also playing a crucial role in sustainable resource management.

Wastewater Treatment and Environmental Remediation

Mixer settlers have found important applications in the treatment of industrial wastewater and environmental remediation projects. Their ability to remove heavy metals and other contaminants from aqueous solutions has made them invaluable in ensuring compliance with stringent environmental regulations. In wastewater treatment, mixer settlers are employed to extract pollutants such as copper, zinc, and other heavy metals through a process known as solvent extraction.

The versatility of mixer settlers allows for the treatment of diverse waste streams, from electroplating effluents to mining runoff. By using specifically tailored extractants, these systems can selectively remove target contaminants, often achieving purification levels that meet or exceed regulatory standards. The continuous operation capability of mixer settlers enables the processing of large volumes of wastewater efficiently, making them suitable for both centralized treatment facilities and on-site industrial applications. This technology not only helps in protecting water resources but also opens up possibilities for recovering valuable materials from waste streams, turning environmental challenges into economic opportunities.

Future Trends and Innovations

Advanced Materials and Nanotechnology

The future of mixer settler technology is closely tied to advancements in materials science and nanotechnology. Researchers are exploring novel materials with enhanced chemical resistance and improved surface properties to boost extraction efficiency. Nanostructured surfaces within mixer settlers could dramatically increase the interfacial area between immiscible liquids, potentially revolutionizing mass transfer rates and separation capabilities.

Emerging materials such as graphene-based composites and advanced ceramics are being investigated for their potential to create more durable and chemically inert mixer settler components. These materials could extend the operational life of equipment and allow for the processing of even more aggressive chemical mixtures. Additionally, the development of smart materials that can change their properties in response to specific stimuli may lead to mixer settlers capable of self-adjusting their performance based on the composition of the mixture being processed.

Integration with Artificial Intelligence

The integration of artificial intelligence (AI) and machine learning algorithms into mixer settler control systems represents a significant leap forward in process optimization. AI-driven systems can analyze vast amounts of operational data in real-time, making predictive adjustments to maintain peak performance under varying conditions. This level of intelligent control can lead to improvements in product purity, energy efficiency, and overall process reliability.

Machine learning models trained on historical process data can identify subtle patterns and correlations that human operators might miss. This capability allows for preemptive maintenance, reducing downtime and extending equipment lifespan. Furthermore, AI-assisted process design could revolutionize how extraction sequences are developed, potentially uncovering novel and more efficient separation strategies for complex mixtures. As these technologies mature, we can expect to see mixer settlers that are not only more efficient but also more adaptable to changing feedstocks and production requirements.

Miniaturization and Process Intensification

The trend towards miniaturization in chemical processing is also influencing mixer settler design. Micro and nano-scale mixer settlers are being developed for applications in pharmaceuticals, fine chemicals, and analytical chemistry. These miniaturized systems offer advantages in terms of reduced reagent consumption, faster processing times, and improved control over reaction conditions. They are particularly valuable in the development of new drugs and materials, where small-scale, high-precision separations are critical.

Process intensification techniques are being applied to mixer settler technology to increase throughput and reduce equipment footprint. This includes the development of high-intensity mixers that can achieve complete phase dispersion in a fraction of the time required by conventional designs. Coupled with advanced settling zone configurations, these innovations could lead to mixer settlers capable of processing significantly larger volumes in compact, modular units. Such advancements would not only improve efficiency but also make mixer settler technology more accessible to a broader range of industries and applications.

Conclusion

Mixer settlers have proven to be transformative in modern purification processes, offering unparalleled efficiency and versatility across diverse industries. From rare earth element extraction to environmental remediation, these devices continue to evolve, incorporating advanced materials, intelligent control systems, and innovative designs. As industries face increasing demands for sustainability and resource efficiency, mixer settlers stand at the forefront of technological solutions. Their ability to adapt to complex separation challenges while maintaining high performance makes them indispensable in shaping the future of purification technologies. With ongoing research and development, mixer settlers are poised to play an even more crucial role in addressing global challenges in resource recovery and environmental protection.

Contact Us

Ready to revolutionize your purification processes? Cuiyan Technology offers cutting-edge mixer settler solutions tailored to your specific needs. Experience the benefits of high extraction rates, perfect separation, and customizable workflows. Contact us today at wangzhijun@cuiyan-tec.com to discover how our advanced mixer settler technology can transform your operations.