How to Set Up Continuous Extractor?

Setting up a continuous extractor can feel daunting, but it's a straightforward process when broken down into manageable steps. Begin by selecting a suitable location with ample space and proper ventilation. Next, assemble the extractor components, ensuring all parts, such as the solvent reservoir, extraction chamber, and collection vessel, are securely connected. Calibrate the system by adjusting flow rates and pressure settings according to your specific extraction needs. Test the setup with a small batch to confirm smooth operation, monitoring for leaks or irregularities. Once everything runs seamlessly, you're ready to scale up production. With careful attention to detail, your continuous extractor will deliver efficient and consistent results every time.

Understanding the Basics of Continuous Extraction

Continuous extraction is a powerful technique used across industries to isolate valuable compounds from raw materials. Whether you're working with metals, chemicals, or natural products, mastering this process can significantly enhance efficiency.

What Is a Continuous Extractor?

A continuous extractor is a specialized piece of equipment designed to perform uninterrupted extraction, separating desired substances from a mixture without halting the process. Unlike batch systems, which require stopping and restarting, this technology allows for a steady flow of materials, boosting productivity. It's widely used in industries like hydrometallurgy, pharmaceuticals, and food processing, where time and precision are critical. By maintaining a consistent operation, this equipment minimizes downtime and maximizes output, making it a cornerstone for large-scale production.

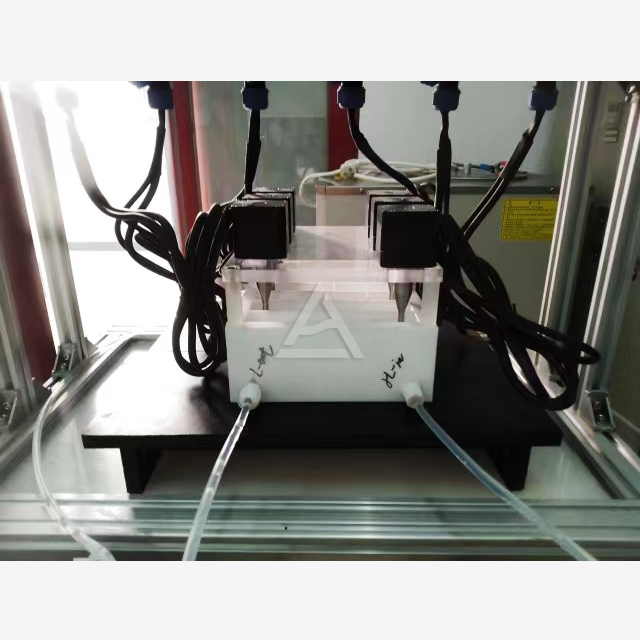

Key Components of Continuous Extraction Systems

Every continuous extraction system comprises several integral parts working in harmony. The continuous extractor includes a solvent reservoir that holds the liquid used to dissolve target compounds, while the extraction chamber is where the magic happens - materials meet the solvent for separation. A collection vessel gathers the extracted product, and a series of pumps and valves regulates the flow. Understanding these components is vital, as improper assembly or calibration can lead to inefficiencies or equipment failure. Familiarizing yourself with each part of the continuous extractor ensures you're equipped to handle setup and troubleshooting with confidence.

Benefits of Using Continuous Extraction Over Batch Methods

Why choose continuous extraction over traditional batch methods? The answer lies in efficiency and scalability. Continuous systems reduce labor by automating the process, allowing for higher throughput with less manual intervention. They also provide consistent quality, as the steady-state operation minimizes variations in output. Energy consumption is often lower, as there's no need to repeatedly heat or cool the system between batches. For industries handling large volumes, such as metal recovery or chemical synthesis, this approach offers a cost-effective and sustainable solution, making it a preferred choice globally.

Step-by-Step Guide to Setting Up Your Continuous Extractor

Now that you understand the fundamentals, it's time to roll up your sleeves and set up your continuous extractor. This section provides a detailed roadmap, ensuring you avoid common pitfalls and achieve optimal performance.

Choosing the Right Location and Environment

The success of your continuous extraction system begins with selecting an ideal location. Opt for a space that's well-ventilated to handle solvent vapors, as poor air circulation can pose safety risks. Ensure the area is free from dust and contaminants, especially if you're working with sensitive materials like pharmaceuticals or precious metals. Temperature control is also crucial - extreme heat or cold can affect solvent performance and equipment longevity. Check that the floor is level to prevent vibrations, which could disrupt the steady flow of materials. Accessibility is another factor; you'll need room to monitor and maintain the system without obstruction.

Assembling and Calibrating the Equipment

With the location secured, it's time to assemble your continuous extractor. Start by laying out all components and cross-referencing them with the manufacturer's manual to ensure nothing is missing. Connect the solvent reservoir to the extraction chamber, ensuring all fittings are tight to prevent leaks. Attach the collection vessel and secure the pumps and valves, paying close attention to their alignment. Once assembled, calibrate the system by setting the flow rate and pressure according to your material and solvent specifications. Run a preliminary test with water or a safe solvent to check for irregularities, adjusting as needed to achieve smooth operation.

Testing and Optimizing the System

Before diving into full-scale production, testing is essential to confirm your setup is flawless. Begin with a small batch of your target material, monitoring the system for consistent flow and output quality. Watch for signs of trouble, such as pressure drops, unusual noises, or solvent leaks, which could indicate loose connections or improper calibration. Analyze the extracted product to ensure it meets your quality standards, adjusting parameters like solvent concentration or flow speed if necessary. Once satisfied, gradually increase the volume, keeping a close eye on performance. Regular maintenance, such as cleaning filters and inspecting seals, will keep your system running at peak efficiency.

Advanced Tips for Maximizing Continuous Extractor Efficiency

Setting up your continuous extractor is just the beginning - optimizing its performance is where true value lies. This section explores advanced strategies to enhance productivity, reduce waste, and ensure long-term reliability.

Selecting the Right Solvent for Your Needs

The solvent you choose can make or break your extraction process. It must effectively dissolve the target compound while remaining compatible with your equipment materials. Consider the solvent's polarity, boiling point, and toxicity, as these factors influence both efficiency and safety. For example, in hydrometallurgical applications, acidic solvents are often used to extract metals from ores, while organic solvents may be better suited for natural product extraction. Test multiple options in small batches to determine which yields the best results without compromising equipment integrity. Always prioritize environmentally friendly solvents to align with sustainability goals and regulatory standards.

Monitoring and Adjusting Process Parameters

A continuous extractor thrives on precision, and monitoring key parameters is the key to maintaining it. Regularly check the flow rate, pressure, and temperature, as even slight deviations can affect output quality. Use automated sensors and control systems to track these variables in real time, allowing for immediate adjustments. For instance, if the pressure rises unexpectedly, it may indicate a blockage in the extraction chamber, requiring prompt intervention. Keep detailed logs of your settings and outcomes to identify patterns and refine your process over time. This proactive approach minimizes downtime and ensures consistent, high-quality results.

Troubleshooting Common Issues

Even with meticulous setup and monitoring, issues can arise. One common problem is solvent carryover, where excess liquid ends up in the collection vessel, diluting the product. This can often be resolved by adjusting the flow rate or installing a more efficient separator. Another frequent challenge is equipment fouling, where residues build up in the extraction chamber, reducing efficiency. Regular cleaning with appropriate solvents can mitigate this, but prevention is better - choose materials and solvents that minimize residue formation. If output quality drops, revisit your calibration settings and solvent choice, as these are often the culprits. Addressing issues swiftly keeps your system running smoothly.

Conclusion

Mastering the setup of a continuous extractor opens the door to efficient, high-quality extraction, whether you're recovering precious metals or producing chemical compounds. By understanding the basics, following a detailed setup process, and applying advanced optimization techniques, you can achieve consistent results while minimizing waste and downtime. Remember, the key lies in careful planning, regular monitoring, and proactive troubleshooting. With these strategies, your extraction process will not only meet but exceed expectations, delivering value to your operations.

Contact Us

Ready to elevate your extraction process? Cuiyan Technology offers cutting-edge continuous extractors tailored to your needs, backed by years of expertise in equipment design and process development. Contact us today at wangzhijun@cuiyan-tec.com to explore how we can help you achieve unparalleled efficiency and quality.

References

Smith, J. A. (2019). "Principles of Industrial Extraction Systems." Chemical Engineering Journal, Volume 45, Issue 3, pp. 123-135.

Patel, R. K. (2020). "Optimizing Continuous Extraction Processes." Journal of Process Engineering, Volume 12, Issue 1, pp. 56-72.

Nguyen, T. H. (2018). "Solvent Selection in Continuous Extraction Applications." Industrial Chemistry Review, Volume 33, Issue 4, pp. 89-102.

Brown, L. M. (2021). "Troubleshooting Extraction Equipment: A Practical Guide." Engineering Today, Volume 19, Issue 2, pp. 34-47.

Garcia, E. S. (2022). "Advances in Continuous Extraction Technology." International Journal of Chemical Processes, Volume 27, Issue 5, pp. 67-81.

Lee, H. Y. (2017). "Energy Efficiency in Continuous Extraction Systems." Sustainable Engineering Reports, Volume 8, Issue 3, pp. 15-28.

VIEW MORECounter Current Extractor

VIEW MORECounter Current Extractor VIEW MORECounter Current Mixer Settler

VIEW MORECounter Current Mixer Settler VIEW MOREMixer Settler For Liquid Liquid Extraction

VIEW MOREMixer Settler For Liquid Liquid Extraction VIEW MOREVanadium Battery Industry Mixer Settler

VIEW MOREVanadium Battery Industry Mixer Settler VIEW MORECopper Electroplating Industry Mixer Settler

VIEW MORECopper Electroplating Industry Mixer Settler VIEW MOREBiological Wastewater Industry Mixer Settler

VIEW MOREBiological Wastewater Industry Mixer Settler VIEW MOREPilot Liquid Liquid Extractor

VIEW MOREPilot Liquid Liquid Extractor VIEW MOREMicro Mixer Settler Unit

VIEW MOREMicro Mixer Settler Unit