Maximizing Mixing and Settling Performance

Optimizing Agitation Parameters

The performance of a mixer settler is fundamentally determined by the efficiency of its mixing stage. To maximize this, agitation parameters must be carefully optimized. The agitator speed - typically adjustable within a range of 100 to 800 RPM - should be calibrated to produce an ideal droplet size distribution. This maximizes the interfacial area available for mass transfer while avoiding the formation of stable emulsions that hinder separation. Utilizing computational fluid dynamics (CFD) simulations can help accurately predict the required agitation intensity tailored to your specific system properties and process objectives.

Enhancing Phase Separation

Efficient phase separation in the settling stage is critical to the overall performance of a mixer settler. Incorporating a patented baffle design can significantly reduce turbulence and bubbling, promoting clearer and more stable separation between phases. Adjustable weirs offer further control by allowing operators to fine-tune the interface level, thereby optimizing separation efficiency. In challenging applications such as those involving high-viscosity fluids or emulsion-prone mixtures, the integration of coalescers or pulsed columns may be necessary to accelerate phase disengagement and improve overall clarity.

Residence Time Optimization

Achieving an optimal residence time in both mixing and settling stages is essential for process efficiency. Insufficient time in the mixer can lead to incomplete extraction, while excessively long durations may reduce throughput and increase operational costs. Tracer studies or real-time monitoring systems are highly recommended to accurately determine the ideal residence time based on the specific chemical system and extraction kinetics involved. It is important to note that the optimal duration may vary significantly depending on the target solute and its mass transfer characteristics.

Advanced Design and Material Considerations

Material Selection for Corrosion Resistance

Choosing the right materials is paramount for longevity and performance. For highly corrosive media (pH 1-14), opt for SUS316L stainless steel or PTFE-lined components. In less aggressive environments, consider more cost-effective options like PP or PVC. For processes requiring visual inspection, transparent PMMA sections can be invaluable. Always factor in chemical compatibility, temperature resistance, and mechanical strength when selecting materials.

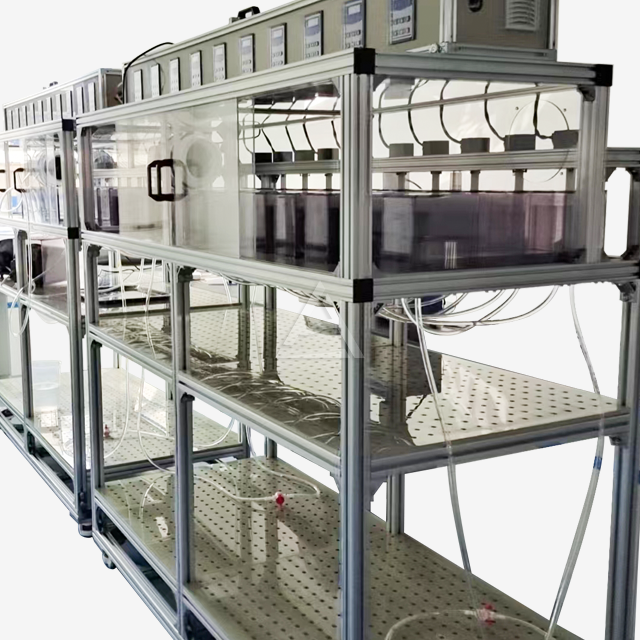

Modular Design for Flexibility

Embrace a modular design philosophy to enhance adaptability. This allows for easy adjustment of the number of mixer settler stages, accommodating changes in process requirements or scaling up operations. Modular designs also facilitate maintenance and reduce downtime during repairs or upgrades. Consider implementing a plug-and-play approach for sensors and control devices to simplify future enhancements.

Innovative Fabrication Techniques

Leverage advanced fabrication methods to improve mixer settler performance. Precision CNC machining ensures tight tolerances, while robotic welding minimizes the risk of leaks. For complex geometries or custom internals, consider additive manufacturing techniques. These methods can create optimized flow paths or intricate baffle designs that are difficult to achieve with traditional fabrication methods.

Process Control and Monitoring Strategies

Implementing Advanced Sensor Systems

Integrate a comprehensive sensor array to monitor critical parameters in real-time. pH probes, temperature sensors, and liquid level detectors connected to a PLC system provide invaluable data for process optimization. Consider implementing inline spectroscopy for continuous monitoring of extraction efficiency. This data-driven approach allows for rapid adjustments to maintain peak performance across varying feed conditions.

Automated Flow Control

Precise control over flow rates is essential for maintaining optimal phase ratios and residence times in mixer settlers. Implement automated flow control systems with feedback loops to ensure consistent performance. Variable frequency drives (VFDs) on pumps allow for fine-tuning of flow rates, while mass flow controllers can maintain accurate phase ratios even with fluctuating feed compositions.

Predictive Maintenance Protocols

Develop a robust predictive maintenance strategy to prevent unplanned downtime and maintain peak efficiency. Utilize vibration analysis on agitators to detect early signs of bearing wear. Implement corrosion monitoring systems, especially in critical areas prone to chemical attack. Regular inspections and proactive replacement of wear items, such as seals and gaskets, can significantly extend the operational life of your mixer settler units.

Conclusion

Optimizing mixer settler performance is a multifaceted endeavor that requires attention to design, materials, and operational strategies. By focusing on agitation parameters, phase separation techniques, and residence time optimization, you can significantly enhance extraction efficiency. Advanced material selection, modular design approaches, and innovative fabrication methods further contribute to improved performance and longevity. Implementing comprehensive process control and monitoring systems enables data-driven optimization and predictive maintenance, ensuring your mixer settler operates at peak efficiency consistently.

Contact Us

Ready to elevate your extraction processes? Cuiyan Technology offers cutting-edge mixer settler solutions tailored to your specific needs. Our expertly engineered systems combine advanced design features with robust materials to deliver unparalleled extraction efficiency. Contact us today at wangzhijun@cuiyan-tec.com to discover how our innovative technology can transform your operations.