Enhanced Extraction Efficiency and Process Control

Optimized Mixing and Settling Dynamics

PP mixer settlers excel in creating ideal conditions for efficient liquid-liquid extraction. The mixing chamber's design promotes thorough blending of immiscible phases, while the settling zone's laminar flow characteristics facilitate rapid phase separation. This optimized design allows for extraction rates up to 95%, significantly outperforming traditional methods. The ability to adjust agitator speed and phase interface height provides operators with precise control over the extraction process, enabling them to fine-tune parameters for specific chemical compositions and desired outcomes.

Customizable Multi-stage Configuration

One of the key advantages of PP mixer settlers is their modular nature, allowing for easy configuration of multi-stage extraction processes. This flexibility enables companies to adapt their setup to varying production requirements or different chemical compounds without significant downtime or equipment changes. The ability to add or remove stages as needed ensures that the extraction process can be optimized for maximum efficiency and product purity, regardless of the complexity of the separation task at hand.

Real-time Monitoring and Adjustment

Advanced PP mixer settler systems often come equipped with integrated sensors for monitoring crucial parameters such as pH, temperature, and liquid levels in real-time. This continuous data stream allows operators to make immediate adjustments to maintain optimal extraction conditions. The ability to respond quickly to process variations not only improves overall efficiency but also helps prevent costly errors and ensures consistent product quality. Additionally, this real-time monitoring capability contributes to enhanced safety protocols and regulatory compliance in chemical processing facilities.

Material Superiority and Design Innovations

Exceptional Chemical Resistance

The use of polypropylene as the primary material in PP mixer settlers offers significant advantages in terms of chemical resistance. PP can withstand a wide pH range (1-14), making it suitable for both highly acidic and alkaline environments commonly encountered in chemical extraction processes. This broad chemical compatibility allows a single PP mixer settler to be used for various extraction tasks, reducing the need for multiple specialized units. The material's resistance to corrosion and degradation also contributes to an extended operational lifespan, typically ranging from 8 to 10 years, thereby lowering long-term equipment costs.

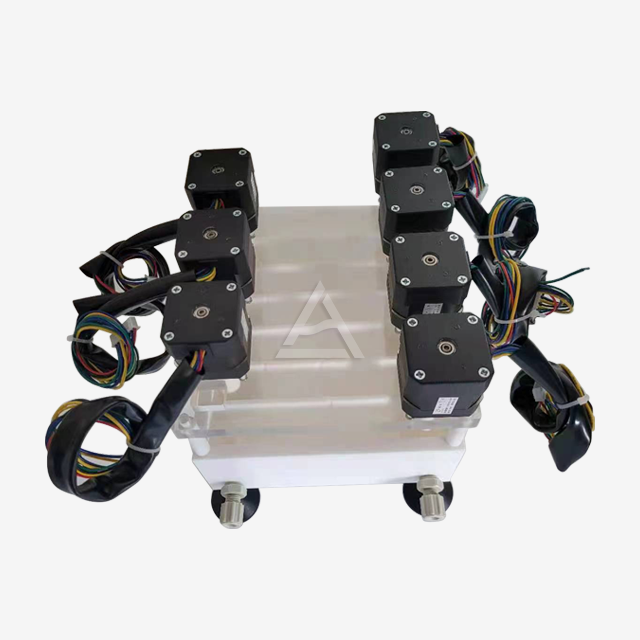

Advanced Fabrication Techniques

The manufacturing process of PP mixer settlers incorporates cutting-edge fabrication techniques that enhance their performance and reliability. Precision laser-cutting ensures exact component dimensions, while ultrasonic welding creates seamless joints that eliminate the risk of leaks. These advanced fabrication methods result in a robust, leak-proof design that can withstand the rigors of continuous operation in demanding industrial environments. The attention to detail in construction not only improves the equipment's durability but also contributes to safer working conditions by minimizing the risk of chemical spills or equipment failures.

Innovative Anti-Bubbling Design

A standout feature of modern PP mixer settlers is their innovative anti-bubbling design. This engineering advancement allows for stable phase separation even at high agitation speeds of up to 1,200 rpm. The ability to maintain clear phase boundaries at such high mixing rates significantly enhances the extraction efficiency without compromising the settling process. This design innovation enables operators to push the boundaries of extraction speed without sacrificing separation quality, leading to increased throughput and improved overall process efficiency in chemical extraction operations.

Versatility and Application Range

Adaptability to Various Chemical Processes

PP mixer settlers demonstrate remarkable versatility across a wide spectrum of chemical industry applications. In metallurgy, they excel in the extraction of rare earth elements, nickel, cobalt, and rubidium, adapting to the unique challenges posed by each element's chemical properties. The equipment's flexibility allows for easy reconfiguration to handle different ore compositions or extraction solvents, making it an invaluable tool in modern metallurgical processes. Beyond metal extraction, PP mixer settlers have proven equally effective in complex separation tasks such as nuclear material processing and isotope extraction, showcasing their adaptability to highly specialized chemical operations.

Revolutionizing Battery Recycling

The growing importance of battery recycling has found a powerful ally in PP mixer settler technology. These systems are particularly adept at handling the complex chemical processes involved in recovering valuable materials from spent lithium-ion, vanadium redox flow, and other types of batteries. The ability to precisely control extraction parameters allows for efficient separation of lithium, cobalt, nickel, and other critical elements from battery waste. This application not only contributes to sustainable resource management but also plays a crucial role in reducing the environmental impact of electronic waste, aligning with global efforts towards a circular economy in the energy storage sector.

Environmental Remediation and Wastewater Treatment

PP mixer settlers are making significant contributions to environmental protection efforts, particularly in the treatment of industrial wastewater and contaminated sites. Their efficiency in removing heavy metals such as lead, arsenic, and mercury from aqueous solutions makes them invaluable in water purification processes. The equipment's resistance to corrosive chemicals allows for the use of aggressive extraction agents when necessary, enhancing the removal of persistent pollutants. Moreover, the scalability of PP mixer settler systems enables their deployment in both large-scale industrial wastewater treatment plants and smaller, on-site remediation projects, offering versatile solutions for a wide range of environmental challenges.

Conclusion

PP mixer settlers represent a significant advancement in chemical extraction technology, offering a combination of efficiency, versatility, and durability that is unmatched by traditional separation methods. Their ability to handle a wide range of chemical processes, from rare earth extraction to environmental remediation, makes them an invaluable asset in the modern chemical industry. As companies continue to seek ways to optimize their operations, reduce environmental impact, and improve product quality, PP mixer settlers stand out as a solution that addresses these needs comprehensively, paving the way for more sustainable and efficient chemical processing practices.

Contact Us

Ready to revolutionize your chemical extraction processes? Cuiyan Technology offers cutting-edge PP mixer settler solutions tailored to your specific needs. Experience the benefits of enhanced efficiency, versatility, and control in your operations. Contact us today at wangzhijun@cuiyan-tec.com to explore how our advanced extraction equipment can transform your chemical processing capabilities.