Proper Installation Techniques for Mixer Settlers

Site Preparation and Equipment Placement

Before installing a mixer settler, careful site preparation is essential. Choose a location with ample space for the unit and associated equipment, ensuring easy access for maintenance and operation. The foundation should be level and capable of supporting the full weight of the mixer settler when filled with liquids. Consider factors such as vibration isolation and chemical resistance when selecting flooring materials.

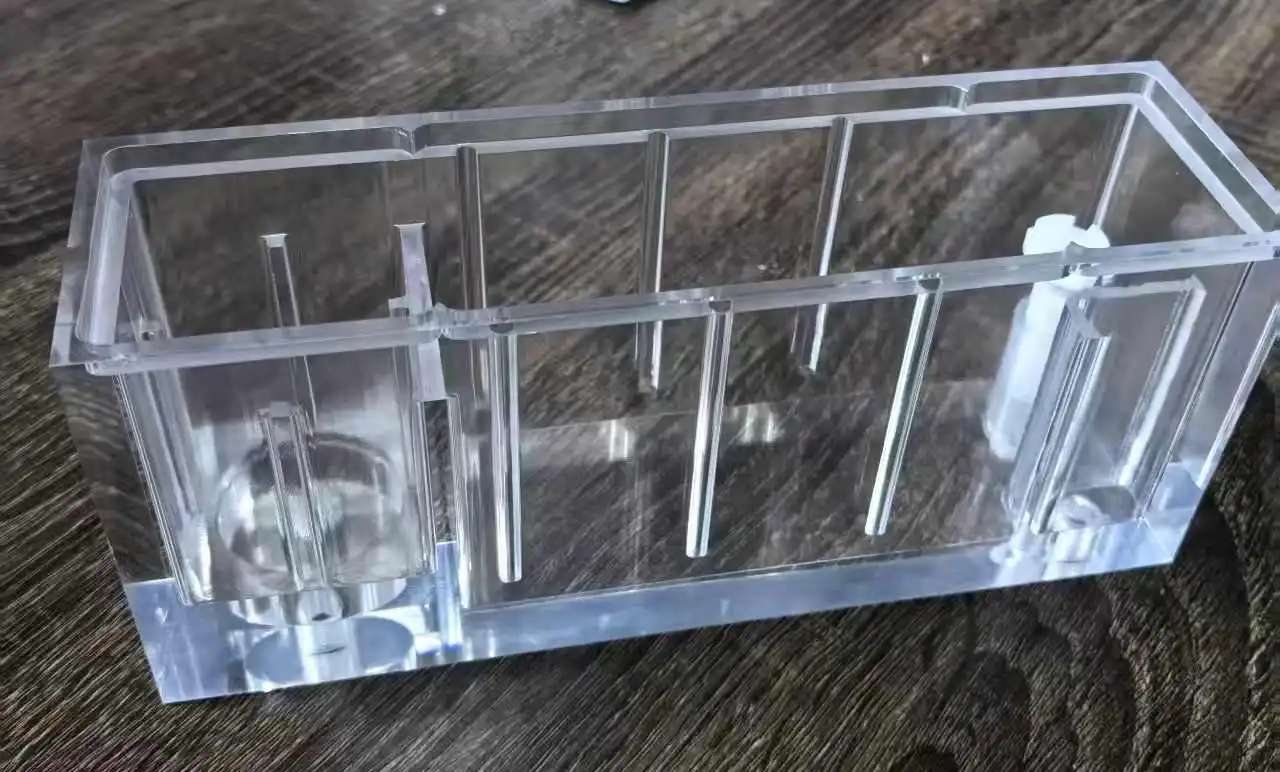

When positioning the mixer settler, allow sufficient clearance around the unit for air circulation and operator movement. If installing multiple units, arrange them in a logical sequence that optimizes process flow. For units with transparent PMMA components, avoid direct sunlight exposure to prevent degradation of the material over time.

Piping and Connections

Proper piping installation is crucial for the safe and efficient operation of a mixer settler. Use materials compatible with the process fluids, such as PP, PVC, or PTFE, depending on the application. Ensure all connections are leak-free by using appropriate gaskets and sealing methods. Install valves at strategic points to allow for easy isolation of individual stages during maintenance.

When connecting inlet and outlet lines, consider using flexible couplings to minimize stress on the mixer settler's fittings. Implement a proper support system for piping to prevent excessive load on the unit. For temperature-controlled processes, insulate piping to maintain thermal efficiency and prevent heat loss or gain.

Electrical and Control System Integration

Integrating the mixer settler's electrical and control systems requires careful planning and execution. Install all electrical components according to local codes and regulations, ensuring proper grounding and protection against potential chemical exposure. For units with advanced features like PLC controls or sensor integration, work with qualified technicians to set up and calibrate the system.

Implement safety interlocks to prevent operation under unsafe conditions, such as low liquid levels or excessive temperatures. Consider installing emergency stop buttons at easily accessible locations around the unit. For applications requiring precise control, such as pH adjustment or temperature regulation, calibrate sensors and control loops to ensure accurate and reliable operation.

Safe Operating Procedures for Mixer Settlers

Startup and Shutdown Protocols

Developing comprehensive startup and shutdown procedures is essential for safe mixer settler operation. Begin the startup process by verifying that all valves are in their correct positions and that the unit is free from debris or foreign objects. Gradually introduce process fluids to prevent sudden pressure changes or air entrapment. Monitor agitator speed and phase interface height closely during initial operation, making adjustments as needed to achieve optimal performance.

For shutdown, implement a stepwise procedure that includes flushing the system with an appropriate cleaning solution to remove residual process fluids. This helps prevent corrosion and contamination between batches. Ensure that all power sources are properly isolated and that the unit is depressurized before performing any maintenance tasks.

Monitoring and Adjustment Techniques

Effective monitoring is key to maintaining safe and efficient mixer settler operation. Train operators to regularly check critical parameters such as flow rates, agitator speed, and phase interface height. For units equipped with sensors, establish clear guidelines for interpreting data and responding to deviations from normal operating ranges.

Implement a system for recording operational data, which can be valuable for troubleshooting and process optimization. When adjustments are necessary, make changes incrementally and observe the system's response before making further modifications. This approach helps prevent sudden disruptions to the extraction process and reduces the risk of accidents.

Emergency Response and Troubleshooting

Preparing for potential emergencies is a crucial aspect of safe mixer settler operation. Develop and regularly review emergency response plans that cover scenarios such as chemical spills, equipment failures, and power outages. Conduct periodic drills to ensure all personnel are familiar with emergency procedures and can respond quickly and effectively.

For troubleshooting, create a comprehensive guide that addresses common issues such as poor phase separation, unexpected pressure drops, or agitator malfunctions. Equip operators with the knowledge and tools to perform basic troubleshooting tasks safely. For more complex problems, establish clear protocols for escalation to maintenance or engineering teams.

Maintenance and Safety Considerations for Mixer Settlers

Routine Inspection and Preventive Maintenance

Implementing a robust preventive maintenance program is essential for ensuring the long-term safety and reliability of mixer settlers. Develop a schedule for regular inspections of critical components such as seals, agitators, and weirs. Check for signs of wear, corrosion, or material degradation, particularly in areas exposed to harsh chemicals or high temperatures.

Pay special attention to the condition of transparent components like PMMA windows, as these can provide early indications of internal issues. Regularly calibrate sensors and control systems to maintain accuracy in process monitoring. Keep detailed records of all maintenance activities and observations to track equipment performance over time and identify potential areas for improvement.

Personal Protective Equipment and Safety Protocols

Ensuring operator safety is paramount when working with mixer settlers, particularly those handling hazardous materials. Establish clear guidelines for the use of appropriate personal protective equipment (PPE) based on the specific chemicals and processes involved. This may include chemical-resistant gloves, safety goggles, face shields, and protective clothing.

Implement rigorous safety protocols for tasks such as sampling, adjusting phase interface height, or performing maintenance. Provide comprehensive training on the proper use of PPE and the importance of following safety procedures at all times. Regularly review and update safety protocols to reflect any changes in equipment, processes, or regulatory requirements.

Handling and Disposal of Chemicals

Safe handling and disposal of chemicals used in mixer settler operations is critical for protecting both personnel and the environment. Develop detailed procedures for the safe transfer of process fluids to and from the mixer settler, including the use of appropriate containment systems and spill response equipment.

Establish clear guidelines for the disposal of waste materials, ensuring compliance with local environmental regulations. This may involve neutralization, treatment, or proper containerization of waste streams. Train operators on the specific hazards associated with the chemicals used in their processes and the appropriate actions to take in case of exposure or spills.

Conclusion

Safe installation and operation of mixer settlers require a comprehensive approach that encompasses proper equipment setup, thorough operator training, and rigorous safety protocols. By focusing on site preparation, careful system integration, and ongoing maintenance, organizations can maximize the efficiency and longevity of their mixer settlers while minimizing risks. Regular monitoring, proactive troubleshooting, and a strong emphasis on safety culture are key to ensuring smooth operations. As extraction processes continue to evolve, staying informed about best practices and emerging technologies will be crucial for maintaining safe and effective mixer settler operations.

Contact Us

Take your extraction processes to the next level with Cuiyan Technology's advanced mixer settlers. Our customizable, energy-efficient designs meet global compliance standards and offer unparalleled performance across various applications. Experience the benefits of our zero-leak technology and expert support. Contact us today at wangzhijun@cuiyan-tec.com to discuss your specific extraction needs and discover how our solutions can optimize your operations.