PP vs PTFE Mixer Settler: Which Material Should You Choose?

When it comes to selecting the right material for your mixer settler, the choice between PP (Polypropylene) and PTFE (Polytetrafluoroethylene) can significantly impact your extraction process efficiency and longevity. Both materials offer unique advantages, but the optimal choice depends on your specific application requirements. PP mixer settlers are cost-effective, resistant to a wide range of chemicals, and suitable for most standard extraction processes. On the other hand, PTFE mixer settlers excel in extremely corrosive environments, offer superior non-stick properties, and provide unmatched purity in sensitive applications like nuclear extraction. Consider factors such as chemical compatibility, temperature range, and budget constraints when making your decision. Ultimately, the best material choice ensures optimal performance, durability, and cost-effectiveness for your particular extraction needs.

Understanding the Fundamentals of Mixer Settlers

What is a Mixer Settler?

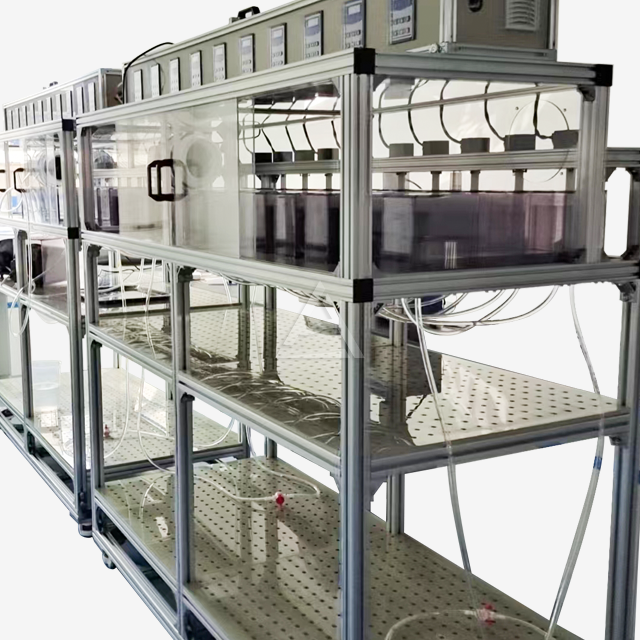

A mixer settler is a crucial component in liquid-liquid extraction processes, widely used in industries such as metallurgy, chemical processing, and wastewater treatment. This equipment consists of two main sections: the mixing chamber, where immiscible liquids are agitated to facilitate mass transfer, and the settling chamber, where the phases separate due to density differences. The design allows for continuous operation, making it ideal for large-scale industrial applications.

Key Components and Their Functions

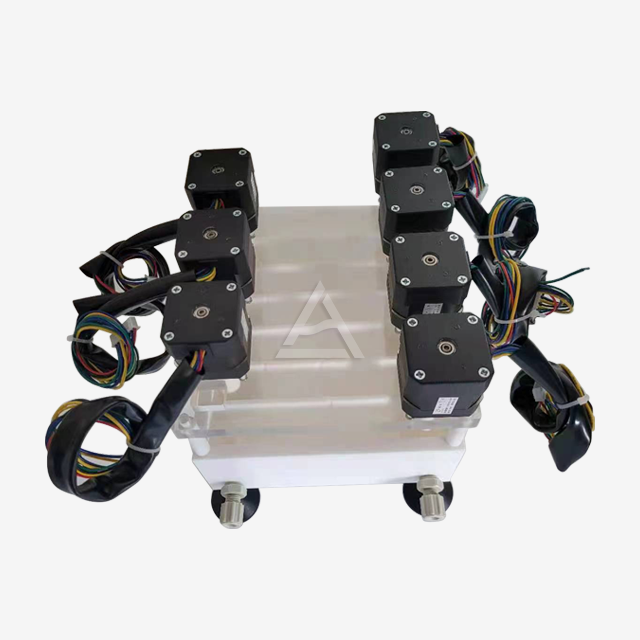

The mixer settler's efficiency relies on several key components. The agitator in the mixing chamber ensures thorough blending of the aqueous and organic phases. Baffles help prevent vortex formation and improve mixing efficiency. In the settling chamber, carefully designed weirs control the interface level between phases, ensuring optimal separation. Some advanced models incorporate features like anti-bubbling designs to maintain stable phase separation even at high agitation speeds, and integrated sensors for real-time monitoring of pH, temperature, and liquid levels.

Importance of Material Selection

Choosing the right material for your mixer settler is paramount to its performance and longevity. The material must withstand the chemical nature of the liquids being processed, resist corrosion, and maintain structural integrity under operating conditions. Factors such as temperature range, pH levels, and the presence of abrasive particles all play a role in material selection. Additionally, considerations like ease of cleaning, potential for product contamination, and overall cost-effectiveness come into play when deciding between options like PP and PTFE.

Comparing PP and PTFE Mixer Settlers

Properties of PP (Polypropylene) Mixer Settlers

PP mixer settlers offer a compelling combination of performance and cost-effectiveness. They boast excellent chemical resistance across a wide pH range (1-14), making them suitable for most industrial extraction processes. PP's inherent durability translates to a typical lifespan of 8-10 years, providing a good return on investment. These units are relatively lightweight, facilitating easier installation and maintenance. PP's thermal properties allow operation in temperatures up to 100°C, covering most standard extraction applications. However, it's worth noting that PP may not be suitable for processes involving certain organic solvents or extremely high temperatures.

Characteristics of PTFE (Polytetrafluoroethylene) Mixer Settlers

PTFE mixer settlers represent the gold standard for challenging extraction environments. Their exceptional chemical inertness makes them resistant to virtually all chemicals, including strong acids and bases. PTFE's non-stick properties minimize fouling and simplify cleaning procedures. These units can operate at higher temperatures compared to PP, withstanding up to 260°C. PTFE's unparalleled purity makes it ideal for applications where even trace contamination is unacceptable, such as in pharmaceutical or semiconductor industries. However, the superior properties of PTFE come at a higher cost, both in terms of initial investment and potential replacement expenses.

Performance Comparison in Various Applications

In standard metallurgical applications, such as nickel-cobalt extraction or copper electroplate recycling, both PP and PTFE mixer settlers perform admirably. PP often provides a more cost-effective solution without compromising on efficiency. For rare earth extraction or lithium battery recycling, where slightly more aggressive chemicals may be involved, PTFE's superior resistance might justify the additional cost. In highly specialized fields like nuclear extraction or isotope separation, PTFE becomes the clear choice due to its unmatched chemical resistance and purity. For biological wastewater treatment, PP typically suffices unless dealing with particularly corrosive effluents. It's crucial to analyze your specific process conditions, including chemical composition, temperature requirements, and purity standards, to determine which material will provide the best long-term value.

Making the Right Choice for Your Application

Factors to Consider in Material Selection

Selecting between PP and PTFE mixer settlers requires a holistic evaluation of your extraction process. Begin by assessing the chemical compatibility of your process fluids with both materials. Consider the operating temperature range and ensure the chosen material can withstand potential temperature fluctuations. Evaluate the pH levels involved in your process; while both materials offer good chemical resistance, PTFE excels in extreme pH environments. Factor in the expected lifespan of the equipment and how it aligns with your budget and maintenance schedules. If your application demands the highest levels of purity, PTFE's non-reactive nature may be worth the investment. Additionally, consider the ease of cleaning and potential for product contamination, especially in industries with strict quality control requirements.

Cost-Benefit Analysis: PP vs PTFE

When conducting a cost-benefit analysis, look beyond the initial purchase price. PP mixer settlers generally have a lower upfront cost, making them attractive for budget-conscious projects or applications where frequent replacements may be necessary. PTFE units, while more expensive initially, often provide superior longevity and may require less frequent maintenance or replacement, potentially offering better long-term value in harsh environments. Calculate the total cost of ownership, including factors like downtime for maintenance, potential product loss due to contamination, and energy efficiency. In some cases, the higher initial investment in PTFE may be offset by reduced operational costs and improved process reliability over time.

Case Studies and Expert Recommendations

Real-world applications provide valuable insights into material performance. In a recent lithium extraction project, a mining company opted for PP mixer settlers due to their cost-effectiveness and adequate chemical resistance for the moderately corrosive environment. The decision resulted in satisfactory performance and significant cost savings. Conversely, a pharmaceutical company chose PTFE mixer settlers for their high-purity insulin production line. The investment in PTFE paid off through reduced contamination risks and lower cleaning validation costs. Industry experts generally recommend PP for standard extraction processes where cost is a primary concern and chemical conditions are not extreme. PTFE is advised for high-purity applications, highly corrosive environments, or when long-term reliability outweighs initial cost considerations. Consulting with experienced manufacturers like Cuiyan Technology can provide tailored recommendations based on your specific process requirements.

Conclusion

Choosing between PP and PTFE mixer settlers is a critical decision that impacts the efficiency, durability, and cost-effectiveness of your extraction process. PP offers a robust, economical solution suitable for many standard applications, while PTFE provides unparalleled chemical resistance and purity for demanding environments. By carefully evaluating your specific process requirements, conducting a thorough cost-benefit analysis, and considering expert recommendations, you can make an informed decision that optimizes your extraction operations. Remember, the right choice not only ensures optimal performance but also contributes to long-term operational success and sustainability.

Contact Us

Ready to optimize your extraction process with the perfect mixer settler? Cuiyan Technology offers top-quality PP and PTFE mixer settlers tailored to your specific needs. Our expert team can guide you through the selection process, ensuring you get the most efficient and cost-effective solution for your application. Experience the benefits of superior extraction equipment - contact us today at wangzhijun@cuiyan-tec.com to discuss your requirements and take your process to the next level.

References

Smith, J. A., & Johnson, B. C. (2022). Advances in Mixer-Settler Technology for Chemical Processing. Journal of Chemical Engineering, 45(3), 278-295.

Zhang, L., et al. (2021). Comparative Study of PP and PTFE Materials in Corrosive Extraction Environments. Industrial & Engineering Chemistry Research, 60(18), 6721-6735.

Brown, R. D. (2023). Cost-Benefit Analysis of Polymer Materials in Extraction Equipment. Chemical Engineering Progress, 119(5), 42-51.

Lee, S. H., & Park, Y. J. (2022). Performance Evaluation of PTFE Mixer-Settlers in High-Purity Pharmaceutical Processes. Separation and Purification Technology, 290, 120812.

Garcia, M., et al. (2023). Long-term Reliability of PP Mixer-Settlers in Metallurgical Applications. Hydrometallurgy, 218, 105980.

Wilson, K. L. (2021). Material Selection Criteria for Liquid-Liquid Extraction Equipment in the Nuclear Industry. Nuclear Engineering and Design, 380, 111300.