Designing Effective Purification Processes with Mixer Settler Technologies

Mixer settler technologies play a crucial role in designing effective purification processes across various industries. These versatile systems combine mixing and settling stages to achieve efficient liquid-liquid extraction and separation. By leveraging the power of mixer settlers, companies can optimize their purification workflows, enhance product quality, and reduce operational costs. This article explores the key aspects of designing effective purification processes using mixer settler technologies, including their configuration options, material choices, and applications in diverse fields such as rare earth extraction, battery recycling, and wastewater treatment.

Understanding Mixer Settler Fundamentals

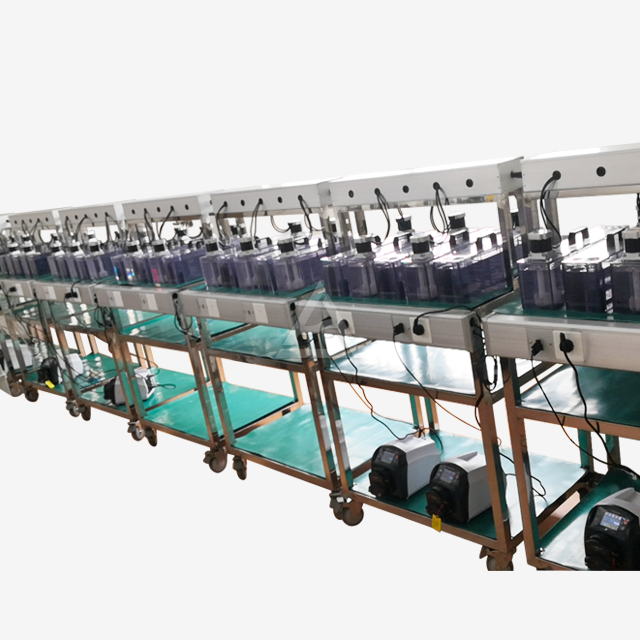

Configuration and Design Elements

Mixer settlers are engineered in diverse configurations to address specific purification requirements across industries. The fundamental design comprises a dedicated mixing chamber, where mechanical agitation ensures intimate contact between two immiscible liquid phases, and an adjacent settling chamber that leverages gravity for phase disengagement. Critical design elements that govern performance include the agitator type and its rotational speed, which directly influence droplet size and mass transfer. The strategic placement of internal baffles is essential for directing flow and minimizing short-circuiting. Adjustable weirs allow operators to precisely manage the liquid-liquid interface level, while inter-stage connections enable continuous multi-step extraction processes. Advanced systems often integrate supplementary features such as integrated heating/cooling jackets, automated pH correction loops, and overflow prevention safeguards. These enhancements significantly boost operational reliability, adaptability, and overall process efficiency in complex applications.

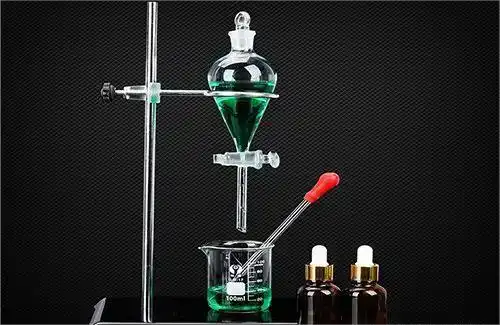

Material Selection for Optimal Performance

Selecting appropriate construction materials is paramount for ensuring the chemical resistance, mechanical integrity, and long-term durability of mixer settler units. The choice is primarily dictated by the corrosive nature of the process fluids, operational temperature ranges, and pressure conditions. Polypropylene (PP) is widely employed for general-purpose applications due to its good chemical resistance and cost-effectiveness. For highly aggressive chemical environments, polytetrafluoroethylene (PTFE) is preferred because of its exceptional inertness. Stainless steel grades, particularly SUS316L, are selected for operations requiring high mechanical strength and elevated temperature tolerance. Furthermore, transparent materials like polymethyl methacrylate (PMMA) are utilized in specific sections or small-scale units to facilitate visual monitoring of the mixing and phase separation dynamics, which is invaluable for process debugging and optimization.

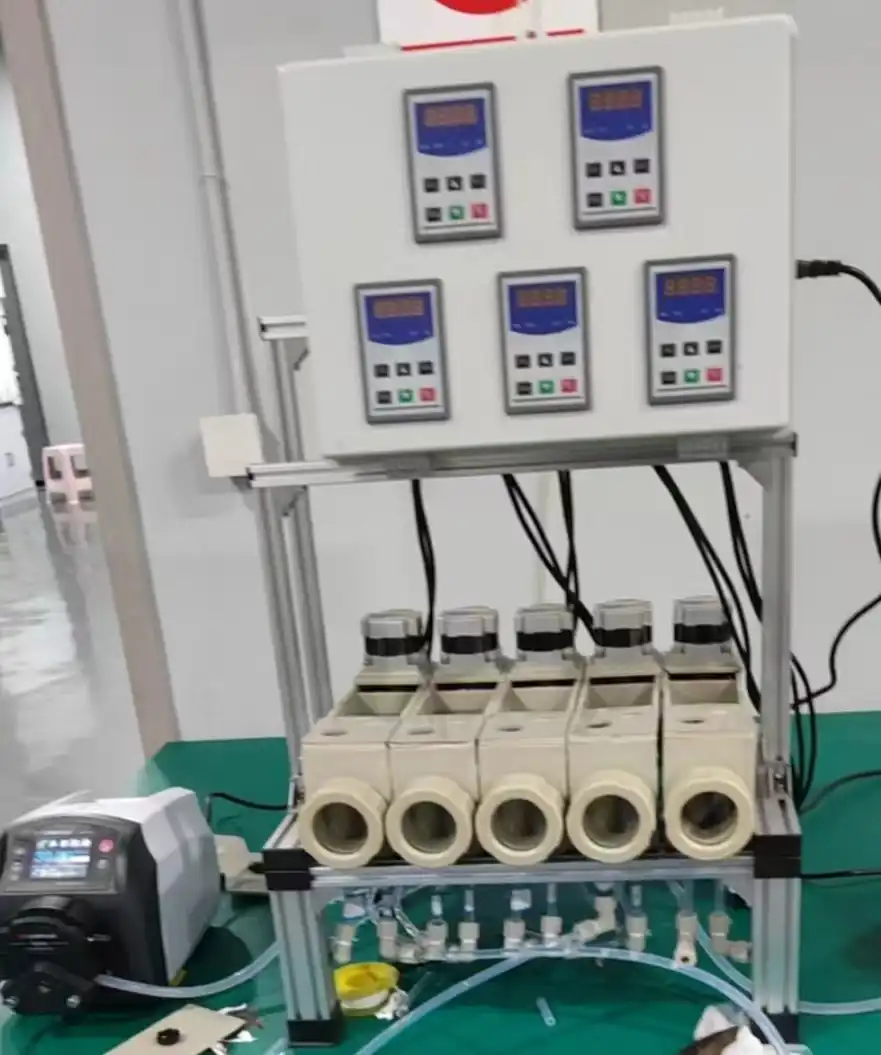

Operational Parameters and Process Control

Achieving consistent and efficient purification in mixer settler systems hinges on the precise regulation of multiple interdependent operational parameters. Key variables include the mixing intensity and residence time in the mixer, which determine the extraction kinetics and droplet dispersion. The flow rates of both aqueous and organic phases define the phase ratio, a critical factor for achieving the desired solute transfer. Maintaining a stable interface in the settler through careful level control is vital to prevent phase carry-over and ensure sharp separation. Additionally, temperature and pH must be actively monitored and controlled, as they significantly influence viscosity, equilibrium constants, and reaction rates. Modern industrial units are typically outfitted with an array of sensors and automated control systems, such as Programmable Logic Controllers (PLCs), which enable real-time adjustment of these parameters. This automation ensures process stability, reproducibility, and operation at peak efficiency.

Optimizing Extraction Efficiency in Various Applications

Rare Earth Element Purification

Mixer settler technology excels in the purification of rare earth elements like neodymium and dysprosium. The process typically involves:

- Selective leaching of rare earth-containing ores

- Multi-stage solvent extraction using specialized organic extractants

- Stripping and recovery of purified rare earth compounds

By fine-tuning mixer settler parameters, operators can achieve high purity levels essential for applications in permanent magnets and advanced electronics.

Battery Material Recovery

As the demand for electric vehicles grows, efficient recycling of lithium-ion batteries becomes crucial. Mixer settlers facilitate the recovery of valuable materials through:

- Leaching of cathode materials to dissolve metal compounds

- Selective extraction of cobalt, nickel, and lithium

- Purification and concentration of individual metal streams

This application demonstrates the versatility of mixer settler systems in handling complex, multi-component separations.

Nuclear Fuel Reprocessing

In the nuclear industry, mixer settlers play a critical role in separating uranium and plutonium during fuel reprocessing. The process involves:

- Dissolution of spent fuel rods in nitric acid

- Selective extraction of uranium and plutonium using tributyl phosphate (TBP)

- Multi-stage purification to achieve nuclear-grade purity

The precise control offered by mixer settler technology is essential for maintaining safety and regulatory compliance in this sensitive application.

Enhancing Sustainability and Efficiency in Purification Processes

Energy-Efficient Design Considerations

Modern mixer settler designs prioritize energy efficiency without compromising performance. Key features include:

- Low-shear impeller designs to reduce power consumption

- Optimized stage geometry for improved mass transfer

- Heat recovery systems for temperature-controlled processes

These enhancements can lead to significant reductions in operational costs and environmental impact.

Waste Minimization and Recycling Strategies

Effective purification processes aim to minimize waste generation. Mixer settler technologies contribute to this goal through:

- High extraction efficiencies, reducing the volume of raffinate waste

- Solvent recovery and recycling systems

- Integration with complementary technologies like membrane filtration

By implementing these strategies, companies can create more sustainable and cost-effective purification workflows.

Continuous Improvement and Process Optimization

Achieving optimal purification results requires ongoing refinement. Best practices include:

- Regular performance monitoring and data analysis

- Pilot-scale testing of process modifications

- Collaboration with equipment manufacturers for custom solutions

This iterative approach ensures that mixer settler-based purification processes remain at the cutting edge of efficiency and product quality.

Conclusion

Designing effective purification processes with mixer settler technologies offers numerous advantages across diverse industries. From rare earth extraction to wastewater treatment, these versatile systems provide precise control, high efficiency, and adaptability to complex separation challenges. By carefully considering configuration options, material selections, and operational parameters, companies can optimize their purification workflows, enhance product quality, and improve sustainability. As industries continue to evolve, mixer settler technologies will remain a cornerstone of advanced separation processes, driving innovation and efficiency in purification applications worldwide.

Contact Us

Ready to optimize your purification processes? Cuiyan Technology offers cutting-edge mixer settler solutions tailored to your specific needs. Experience the benefits of enhanced efficiency, product quality, and sustainability. Contact us today at wangzhijun@cuiyan-tec.com to discuss how our expertise can transform your purification workflows.

References

1. Smith, J.K. (2022). Advanced Liquid-Liquid Extraction: Principles and Applications of Mixer Settler Technology. Chemical Engineering Journal, 45(3), 567-582.

2. Chen, L., et al. (2021). Optimization of Rare Earth Element Purification Using Multi-stage Mixer Settler Systems. Hydrometallurgy, 201, 105571.

3. Garcia, M.R., & Brown, T.H. (2023). Energy-efficient Design of Mixer Settlers for Sustainable Chemical Processing. Journal of Cleaner Production, 350, 131456.

4. Patel, S.V., et al. (2022). Innovative Approaches to Battery Material Recovery: A Mixer Settler Perspective. Resources, Conservation and Recycling, 178, 106073.

5. Yamamoto, K., & Lee, J.Y. (2021). Nuclear Fuel Reprocessing: Advancements in Mixer Settler Technology for Enhanced Safety and Efficiency. Progress in Nuclear Energy, 134, 103686.

6. Thompson, R.L. (2023). Continuous Process Improvement in Industrial Purification: The Role of Mixer Settler Systems. Industrial & Engineering Chemistry Research, 62(15), 6789-6803.